There are many types of pallet roller conveyors, such as roller type, chain type, roller type, plate type, lifting table, etc. This picture shows the types of pallet roller conveyor systems. In addition to roller type, there are other types to meet your needs.

Description

Pallet Roller Conveyor

Pallet roller conveyor is a kind of equipment in pallet roller conveying system, and we use it for horizontal transportation of pallet goods. Its working principle mainly includes the following aspects.

First of all, the transmission mode of the pallet roller conveyor is roller or chain drive. It is through the motor to start the conveying chain or roller on the conveyor. The choice of transmission mode depends on the specific requirements of the work site and the type of conveyor.

Secondly, when the conveyor chain or roller starts to rotate, friction and gravity push the stacked goods placed on the conveyor forward. Certain guide devices are usually installed on the conveyor.

In addition, people need sort and merge palletized goods. People usually equip pallet conveyors with sorting devices or merging devices. The merging device merges the goods on multiple conveyor lines into one, improving logistics efficiency and reducing space occupancy.

Finally, there are equipment such as unloading stations or conveyor belts, which we usually install at the end of the conveyor belt. Finally, the goods are unloaded from the conveyor belt or transferred to subsequent workstations. So we can customize these equipment according to specific needs to ensure the safe and efficient transportation of goods.

In conclusion

To sum up, the working principle of the pallet conveyor is to use the motor to drive the conveyor chain or roller to start running. And use friction and gravity to push the goods forward. And then cooperate with the guide device to ensure that the goods run along the correct path. And cooperate with the sorting and merging device to realize the sorting and merging of goods.

Finally, the goods are unloaded or delivered through unloading stations or conveyor belts. It is widely used in warehousing logistics, production and manufacturing and other fields to improve logistics efficiency and reduce labor costs.

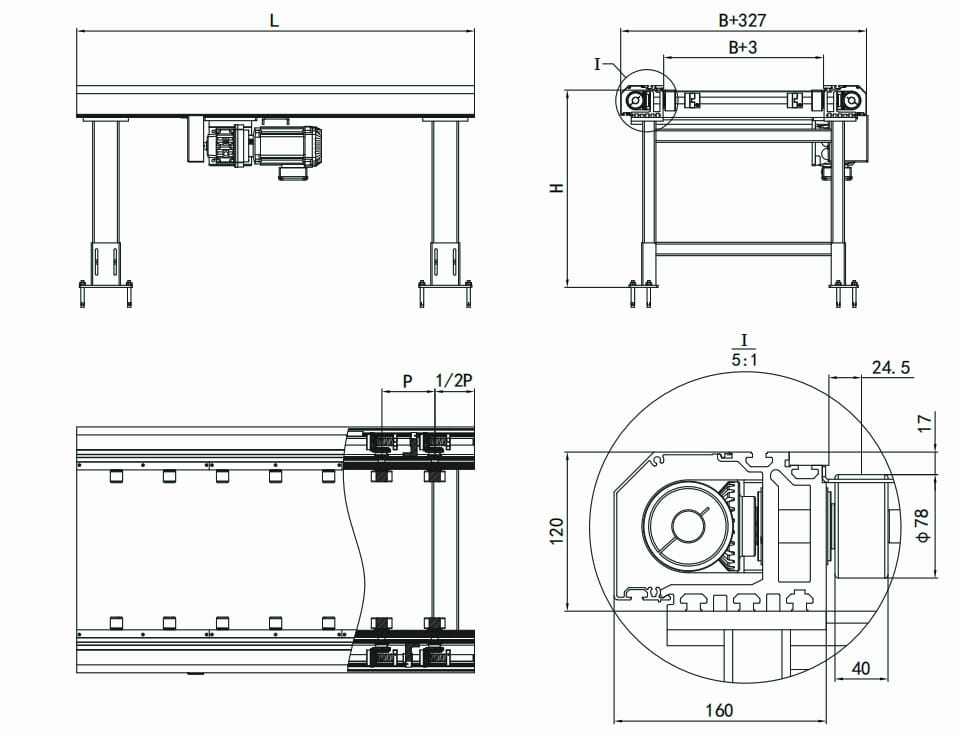

Pallet Roller Conveyor Specifications:

Model Conveyor length L Conveyor width W Conveyor height H Conveyor speed V Roller spacing P

TOSH-5-GC 1000~6000mm 300~1200mm As needed 3~15m/min 160/200/250mm

Product Features:

- High degree of modularization, complete supporting mechanism and easy maintenance.

- Conveying medium: roller.

- The production line frame is made of special high-strength aluminum profiles, connected by standardized profiles, with a double-sided cantilever structure and bevel gear transmission.

- Suitable for heavy pallet conveying, it can realize automatic circulation and flexible control of pallets.

- Total load ≤2500KG.

- Suitable for cumulative conveying.

Size Description

Pallet Roller Conveyor System Applications:

TOSH-5: Mainly used in heavy-load situations, with a sturdy structure and capable of withstanding large impact loads. So people often use it in automatic assembly production lines for automobile engines and gearboxes.

Purpose of Pallet Roller Conveyor

Pallet roller conveyor is a mechanical equipment in industrial production and logistics transportation. We mainly use it to transport various types of pallets, containers and other items. It can transport items quickly and efficiently on the production line or in the warehouse.

We widely use pallet roller conveyors and commonly find them in the manufacturing, logistics, food, chemical and other fields. In the manufacturing industry, people widely use them in production lines such as automobile manufacturing, electronic product manufacturing, and mechanical processing. In the logistics industry, they are important equipment for cargo transportation.

In the food and chemical industries, due to the involvement of dust, electronics and other factors, the use of pallet roller conveyors can avoid the harm of these factors to the human body, while ensuring the safety and hygiene of the goods.

Advantages of Pallet Roller Conveyors

1. Improve production efficiency

The pallet roller conveyor can realize the automatic operation of the production line. And it can reduce labor costs, and quickly and efficiently transfer items from the receiving point on one production line to the receiving point on another production line, greatly improving production efficiency.

2. Cost savings

The use of pallet roller conveyors can save a lot of labor costs, reduce the labor intensity and working hours of workers. And reduce the cost of machinery maintenance.

3. Improved security

The pallet roller conveyor adopts multiple safety measures such as emergency stop switch, limit switch, tensioning device, etc. to ensure safety during production and transportation.

4. Improve logistics efficiency

The use of pallet roller conveyors can enable items to be transported quickly and efficiently on the production line or in the warehouse, improving logistics efficiency.

5. Strong flexibility

People can set the conveying direction of the pallet roller conveyor flexibly to meet different conveying needs. At the same time, people can transport items of different shapes and sizes safely and quickly on the pallet roller conveyor.

In short, as an important mechanical equipment, pallet roller conveyor can help enterprises realize production automation. Besides, it can improve logistics efficiency. And it can reduce labor costs and machinery maintenance costs, ensure production safety. So it has a very broad application prospect.