Powered roller conveyor line is a motorized material handling system. We design it to transport goods swiftly and efficiently through production, packaging, or distribution environments. It’s a vital component in modern manufacturing, warehousing, and distribution operations, optimizing throughput, and minimizing the need for manual handling.

Description

Powered Roller Conveyor Line

Powered roller conveyor line is a common conveying equipment, mainly composed of powered rollers, brackets, driving devices and other accessories. Its working principle is to drive the motor to rotate the power drum, thereby driving the goods for transportation. This kind of conveyor line has the advantages of simple structure, easy maintenance and low cost, and is suitable for conveying goods of various weights, sizes and shapes.

Compared with other types of conveyor lines, power roller conveyor lines have higher conveying efficiency and are highly adaptable to various terrains and environments. However, due to its limited load-bearing capacity, powered roller conveyor lines are usually suitable for conveying small and medium-sized materials.

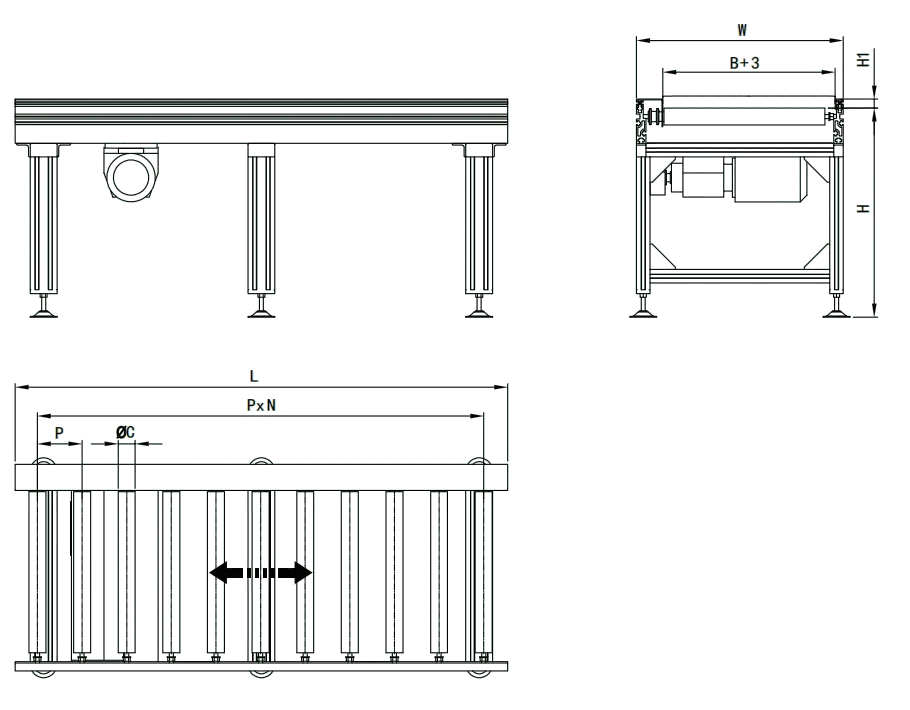

Specifications:

Model Conveyor Length L Conveyor Width W Conveyor Height H Conveyor Speed Roller Spacing P

TOSH-RL-P 600~6000mm 120~1200mm As needed Max 20m/min Selective

Product Features:

- Simple and reliable structure with low maintenance;

- Roller diameters: φ38, φ50.6, φ60, φ76, φ80, φ89… selectable based on requirements.

- Conveys mediums are made of materials such as carbon steel, stainless steel, plastic, etc. Surface options include rubber coating, selectable as needed.

- T -slot aluminum profiles frame for easy accessory attachment

- Maximum load of up to 250kg/m, capable of withstanding significant impact loads, catering to various conveying needs.

- Adjustable stacking force, suitable for accumulation conveying.

Dimensional Description:

Application of Powered Roller Conveyor Line

As we can learn, the power roller line is an efficient conveying equipment widely used in modern industrial production fields. The power drum line relies on the motor to drive the drum to rotate. The rotation of the drum drives the material to be transported, and the goods are transported smoothly. Let me share with you the application of power drum line:

- Warehousing and logistics: Power roller lines are widely used in modern warehouse management systems, especially automated three-dimensional warehouses and distribution centers.

- Express logistics: Powered roller lines play an important role in the field of express logistics, especially in express sorting centers. With the help of highly automated roller lines, a series of operations. Such as automatic sorting, weighing, billing, and packaging of express items can be realized, which greatly improves the efficiency of express logistics operations.

- Manufacturing industry: We usually use power roller lines widely in manufacturing production lines, such as home appliances, food, chemicals, stationery and other production and packaging operations. It can realize automatic transportation, buffering, accumulation, steering and other functions of materials, improving the automation and work efficiency of the production line.

- Convenience store warehousing industry: The power roller line can help the convenience store warehousing industry complete the transportation, sorting and transportation of various goods.

Advantages of Powered Roller Conveyor Line

1. Streamlined Material Delivery: Featuring rollers as its primary mechanism, the roller conveyor facilitates swift and consistent movement of items along its path. This leads to a superior level of efficiency in handling, making it an excellent choice for rapid transport needs in diverse settings.

2. Steady Material Handling: With rollers spaced at even intervals, materials are less likely to experience excessive jostling during transit, which helps maintain a stable journey along the conveyor. This attribute makes the roller conveyor particularly beneficial for the movement of items that are delicate or prone to damage.

3. Quiet Operation: The roller conveyor operates with a reduced level of sound, making it a discreet addition to environments where maintaining a low noise level is essential.

4. Hassle-free Upkeep: The straightforward design of the roller conveyor allows for easy maintenance. Regular inspections for roller wear and prompt replacement of any worn elements ensure the conveyor remains in top working condition.

5. Durable Construction: Crafted from premium materials, the roller conveyor boasts a lengthy operational life, exemplifying durability and reliability in material conveyance.

The Function of Powered Roller Conveyor Line

As we can see, the power drum line is a conveying equipment based on the principle of drum wheel motion. It mainly consists of rollers, drives and support structures. Through external power input, the rollers are driven to rotate, so that the items are transported along the direction of the rollers. Compared with traditional manual handling, lifting machinery, etc., the power drum line has the following two significant functions.

The Importance of Power Roller Conveyor Line

1. Improve Production Efficiency

Powered roller lines can realize automated transportation, making the transfer of items during the production process more efficient and faster. This equipment is suitable for transporting different types of items. Such as boxes, packages, tires, wooden boards, etc., and we can adjust conveying speed flexibly as needed.

Operators on the production line only need to place items on the power roller line. Then they can be transported automatically, thus saving a lot of labor and time costs.

2. Improve Production Safety

Besides, powered roller lines can effectively avoid potential dangers caused by manual handling of items through automated transportation. In this process, employees do not need to carry heavy objects manually. Thus avoiding adverse consequences such as occupational diseases and personal injuries.

At the same time, the power drum line can also be equipped with sound and light alarm prompts. Besides, emergency stopping measures as needed to ensure safer and more reliable transportation during transportation.

3. The Importance of Powered Roller Conveyor Line in the Logistics Industry

In the logistics industry, the power drum line is an essential piece of equipment. Its application in the field of high-tech logistics has become more and more widespread. It can not only improve the process and efficiency of the logistics supply chain. But also increase transportation safety and personnel health.

At the same time, as modern enterprises have increasingly higher requirements for product quality, power drum lines are receiving more and more attention. So it can make them one of the key equipment to improve the competitiveness of enterprises.

In Conclusion

As a common logistics conveying equipment, the power roller line plays an important role in modern manufacturing and logistics industries. Because it can improve production efficiency and production safety through automated transportation. At the same time, due to its increasingly prominent importance in logistics companies, companies need to pay more attention to the selection and maintenance of power drum lines to adapt to the rapidly developing business environment.