Flexible Chain Conveyor (Flexible Chain Conveyor) is a special conveying equipment composed of multiple chain links that can be used to transport and handle materials in manufacturing, logistics, warehousing and other fields.

Description

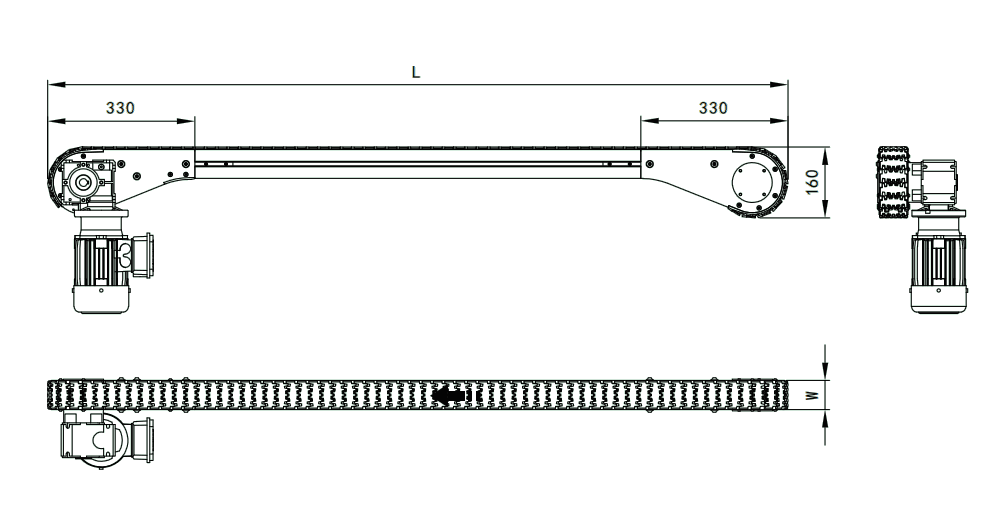

Aluminum Frame Chain Conveyor

With the continuous development of industrial production, flexible chain conveyors, as an efficient and practical conveying equipment, play an increasingly important role in modern production lines. This article will focus on the application fields, working principles, advantages and future development trends of flexible chain conveyors.

Working Principle of Flexible Chain Conveyor

Flexible chain conveyor consists of transmission device, chain, slideway, bracket and other parts. Its main working principle is to drive the chain to rotate through the motor. So that the materials on the slide are transported according to the preset path. The material and structure of the chain are selected according to different application situations. And material characteristics to ensure stability and reliability during the transportation process.

Specifications:

Model Conveyor Length L Conveyor Width W Conveyor Height H Conveyor Speed V

TOSH-FC 800~20000mm 44/63/83/103mm As needed Max 20m/min

Product Features:

- Simple and reliable structure with low maintenance;

- Conveys mediums are made of POM,Surface options include rubber coating, selectable as needed. ensuring smooth transportation with low friction.

- Available chain plate widths include 44/63/83/103, operating in one direction without the ability to reverse.

- T -slot aluminum profiles frame for easy accessory attachment

- Maximum load capacity of reaches 120kg, suitable for industries such as pharmaceuticals, food, cosmetics, etc.

- Flexible line layout, compact structure, small turning radius, enabling spatial layouts for turns and inclines

Dimensional Description:

Application Fields of Flexible Chain Conveyors

The flexible chain conveyor is a conveying equipment based on chain drive. So we use it widely in production lines in food, beverage, pharmaceutical, chemical, tobacco and other industries. Its main function is to transport materials from one station to another to achieve automated production. In modern production lines, flexible chain conveyors have become one of the indispensable and important equipment.

Advantages of Aluminum Frame Chain Conveyor

- High Efficiency and Stability: The flexible chain conveyor utilizes a chain-driven mechanism. So it offers superior transmission proficiency and consistent operation, well-suited for the demands of diverse production lines.

- Exceptional Adaptability: We can design to customize for various production layouts and material types, the flexible chain conveyor can handle substantial loads. and resist friction, making it capable of performing in a range of challenging environments.

- Simplified Maintenance: Fewer components and a straightforward structure make the flexible chain conveyor easy to upkeep. The durable chain material boasts resistance to wear and corrosion, enhancing the lifespan of the system.

- Dependable Safety: Operation of the flexible chain conveyor is smooth and reliable, greatly reducing risks associated with material spills and blockages. Thereby boosting the safety and dependability of production processes.

- Space Efficiency: The adjustable nature of the flexible chain conveyor allows for an efficient use of space within production lines, contributing to elevated operational efficiency.

- Tailor-Made Solutions: Flexible chain conveyors are fully customizable, with options for various lengths, widths, heights. And speeds to cater to the unique requirements of different businesses.

- Cost Savings: Adopting a modular design, we can assemble or disassemble the flexible chain conveyor system easily, curbing production and maintenance expenses. Plus, its stable and energy-efficient operation can further diminish overall production costs.

The Future Development Trend of Flexible Chain Conveyors

With the continuous development of Industry 4.0 and intelligent manufacturing, flexible chain conveyors will show the following development trends in the future:

- Intelligent: Flexible chain conveyors in the future will be more intelligent, capable of remote control, fault diagnosis, data monitoring and other functions. Besides, it can further improve the automation and intelligence level of the production line.

- Modularization: The modular design of the flexible chain conveyor will be more complete, facilitating rapid assembly and disassembly. And shortening production line debugging and maintenance time, and improving production efficiency.

- Green and environmentally friendly: Future flexible chain conveyors will pay more attention to environmental protection. Besides, energy-saving design, using low-noise, low-energy-consumption motors and materials to reduce the impact on the environment.

- Multi-functionality: In the future, flexible chain conveyors will have richer functions. They can not only realize the transmission of materials, but also realize various functions. Such as material processing and detection, further improving the degree of integration of the production line.

- Customized services: In the future, flexible chain conveyor companies will pay more attention to customer needs. And provide more personalized and customized services to meet the special needs of different industries and companies.

What are the Application Ranges of Flexible Chain Conveyors?

Its application scope includes but is not limited to the following aspects:

- Manufacturing: In manufacturing, we can use flexible chain conveyors to transport parts. Or assembled products from one workbench or workstation to another. Thereby enabling automation and continuous production of production lines. Besides, we can widely use in automobile manufacturing, electronic product assembly, home appliance production and other fields.

- Logistics and warehousing: In the field of logistics and warehousing, we can use flexible chain conveyors for sorting, loading, unloading, and long-distance transportation within warehouses. Moreover, it can greatly improve cargo handling efficiency and reduce manual handling costs. And is suitable for express sorting centers, logistics parks and other places.

- Food and Beverage Industry: In the food and beverage industry, we can use flexible chain conveyors to transport food packaging, bottled beverages, cans and other products from the production line to the packaging line, and we can also use it to transport packaged food products to storage areas or transport area.

- Pharmaceutical and chemical industry: In the pharmaceutical and chemical industry, we can use flexible chain conveyors to transport pharmaceuticals, chemicals and various raw materials, as well as transport finished products to packaging or sub-packaging areas.

- Electronics industry: In the electronics industry, we can use flexible chain conveyors to transport electronic components, electronic equipment, and assembled electronic products, such as mobile phones, computers, etc.

- E-commerce industry: In the e-commerce industry, we can use flexible chain conveyors for order processing, cargo sorting and packaging. It can improve warehousing and logistics efficiency, and meeting the need for fast delivery.

Conlusion

Generally speaking, flexible chain conveyors are suitable for places that require efficient, continuous, and automated material transportation. It can replace traditional manual handling methods, improve work efficiency, and reduce production costs. However, during selection and application, factors such as cargo type, size, weight, and transportation distance must be considered based on specific circumstances. So it can ensure that the appropriate flexible chain conveyor is selected to meet actual needs.