An Overhead Chain Conveyor is a high-efficiency material handling system designed for transporting goods along a predefined overhead path. Utilizing a continuous chain mechanism, it can move items through various production stages without occupying valuable floor space, optimizing vertical space in a facility.

Description

Overhead Chain Conveyor

The conveying surface of the overhead chain conveyor is flat and smooth, with low friction. So the material transitions between conveying lines is smooth. Besides, It can convey many types of glass bottles, PET bottles, cans and other materials, as well as many types of luggage.

Chain plate material

In a word, we can select carbon steel, stainless steel, thermoplastic chains, chain plates of different widths and shapes according to the needs of your products to complete plane transportation, plane turning, lifting, lowering and other requirements

Chain Plate Specifications

The width of direct transmission chain plate is 63.5, 82.6, 101.6, 114.3, 152.4, 190.5, 254, 304.8;

The width of the turning chain plate is 82.6, 114.3, 152.4, 190.5, 254, 304.8

Application

In fact, we can use it in the automatic transportation, distribution, and on-line transportation of post-packaging of food, cans, medicines, beverages, cosmetics and detergents, paper products, condiments, dairy and tobacco, etc.

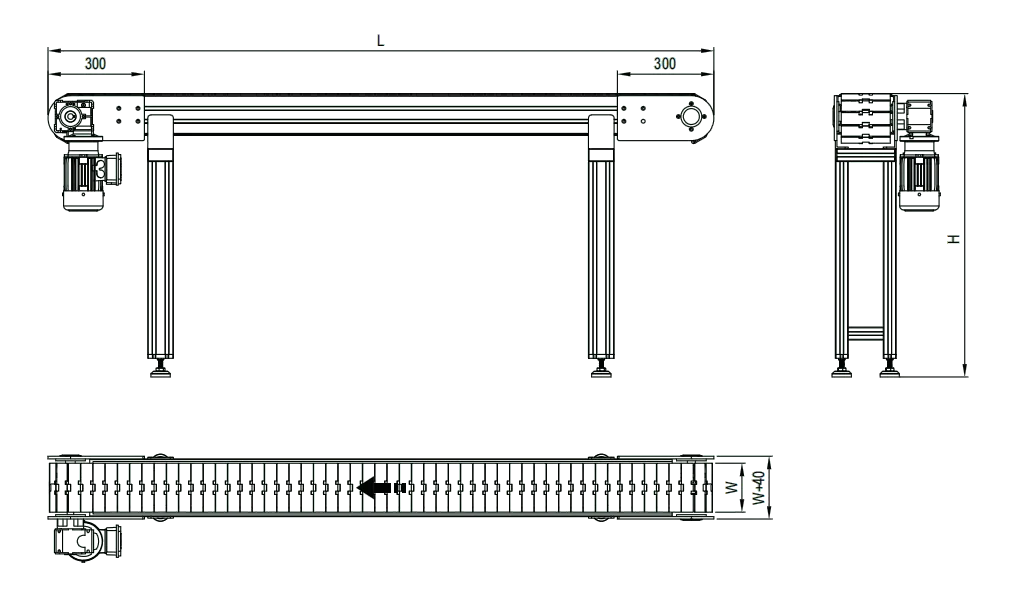

Specifications:

Model Conveyor Length L Conveyor Width W Conveyor Height H Conveyor Speed V

TOSH-TC 1000~20000mm 82.6/114.3/152.4/190.5/254/304.8mm As needed Max 20m/min

Chain Conveyor Product Features:

- Simple and reliable structure with low maintenance;

- Conveys mediums are made of POM,Surface options include rubber coating, selectable as needed. So it ensures smooth transportation with low friction.

- Available chain plate widths include 82.6/114.3/152.4/190.5/254/304.8,operating in one direction without the ability to reverse.

- T -slot aluminum profiles frame for easy accessory attachment

- Maximum load capacity of reaches 300kg, suitable for industries like casting, manufacturing, food, beverages, etc.

Dimensional Description:

Different Types of Overhead Chain Conveyors and Their Features

Chain Conveyor

1. Chain plates are made of stainless steel, engineering plastics and other materials, with a wide range of specifications. We can select them according to the conveyed materials and process requirements, and can meet the different needs of various industries.

2. It has large conveying capacity and can carry larger loads, such as in electric vehicles, motorcycles, generators and other industries;

3. The conveying speed is accurate and stable. So it can ensure precise synchronous conveying.

4. We generally can wash chain conveyors directly with water or soaked in water. Besides, the equipment is easy to clean and can meet the hygiene requirements of the food and beverage industry.

5. Flexible equipment layout. Horizontal, inclined and turning conveying can be completed on one conveying line.

6. Besides, the equipment has a simple structure and is easy to maintain.

Overhead Chain Conveyor

The chain plate conveyor uses a standard chain plate as the load-bearing surface and a motor drives it. So we can make the chain plate conveyor very wide and form a differential speed by running multiple rows of chain plates in parallel, using the speed of the multiple rows of chain plates.

But the difference makes multi-row conveying become single-row conveying without squeezing. Thereby meeting the requirements of single-row conveying of beverage labeling, filling, cleaning and other equipment.

It can also turn single-row into multi-row and move slowly, resulting in storage In order to meet the large-volume material requirements of sterilizers, bottle storage tables, and bottle cooling machines. Besides, we can make the head and tail of the two chain plate conveyors into overlapping mixing chains so that the bottle (can) body is in a dynamic transition state.

So it can make the bottle (can) body in a dynamic transition state. Although, there is no retained material on the conveyor line. So it can meet the pressure and pressure-free conveyance of empty bottles and full bottles.

Other Chain Conveyors

The curved chain plate conveyor uses a standard chain plate as the load-bearing surface and a motor reducer drives it . So we can make the chain plate conveyor very wide and form a differential speed by running multiple rows of chain plates in parallel. The speed difference causes multi-row conveying to become single-row conveying without extrusion,

Thereby, meeting the requirements for single-row conveying of beverage labeling, filling, cleaning and other equipment. Besides, the conveyor chain plates are available in three types: POM material, stainless steel and stainless iron. So there are two types of turning: winged turning and magnetic turning.

The turning chain plate conveyor uses π-shaped turning chain plates as the conveyor carrier. The chain plates run in the turning guide rails made of polymer polyethylene. Or we use stainless steel turning chain plates and magnetic turning guide rails to keep the conveyor chain plates running all the time.

Inside the special guide rail, it has the characteristics of smooth operation and easy installation. So we can use it widely in food, beverage, electronics, packaging, medicine and other industries.

Besides, the conveying surface of the curved chain plate conveyor is flat and smooth, with low friction. So it conveys the materials between the conveying lines. The transition is smooth and can transport various types of glass bottles, PET bottles, cans and other materials, as well as various types of luggage.

Conveying Line Characteristics

- The direction is fixed, and some can be adjusted.

- Conveying line, each group is composed of rollers, each unit can be used independently. Or multiple units can be connected and used, and it is easy to install;

- In the conveying assembly line, the ratio of the longest to the shortest state of a unit can reach 3 times;

- The equipment performance is guaranteed. And can adapt to work in any harsh places (high temperature, dust).

- The chain plate conveyor uses the chain plate as the traction and load carrier transportation tool. The chain can be an ordinary sleeve roller conveyor chain, or we can use some other special chains;

- The transport capacity is large and can carry heavy weight;

- High automation, multi-function,

- It is convenient for accumulation and transportation, and we can use it for assembly and development lines or for storage and transportation of items;

- The speed is correct and stable during the conveying process, which can ensure accurate and synchronous conveying; 10. The structure is simple, the appearance is exquisite, practical and noiseless;

In Conclusion

But the origin of conveyor lines is very early, the truly modern conveyor lines originated from Britain during the Industrial Revolution. Today, there are a wide range of conveyor lines that we can use for material transportation in various industrial productions. As we know, the conveyor line mainly completes the task of conveying materials.

In the area surrounding the warehouse, production workshop and packaging workshop, there are conveyor chains composed of many belt conveyors, roller conveyors, mesh belt conveyors, plate chain conveyors, etc., connected end to end to form a continuous conveyor line.