The Toshine Pallet Conveyor is a robust and efficient solution designed to streamline the transportation of heavy and bulky loads in various industrial settings. Engineered for durability and performance, this conveyor system is ideal for manufacturing, warehousing, and distribution applications.

Description

Reliable Heavy Load Pallet Conveying and Handling by Toshine

At Toshine, we specialize in designing pallet conveyors that are perfect for moving and handling heavy loads. Meanwhile, we tailor our conveyors to optimize operations in manufacturing, warehousing, and distribution centers. Besides, we utilize advanced technology to meet the specific needs of your processes, ensuring everything runs smoothly and efficiently.

Our pallet conveyors boost efficiency and adaptability when it comes to moving heavy items, and they also help cut down on overall operational costs. Meanwhile, this high-performance technology creates a more ergonomic workflow, reducing the need for operators to engage in heavy lifting.

The skilled engineers at Toshine work closely with you to implement the best solution, whether you need a standalone conveyor or a fully integrated automated material handling system. So with Toshine, you can trust that your material handling operations will be elevated by our reliable pallet conveyors!

How Toshine Pallet Conveyors Work

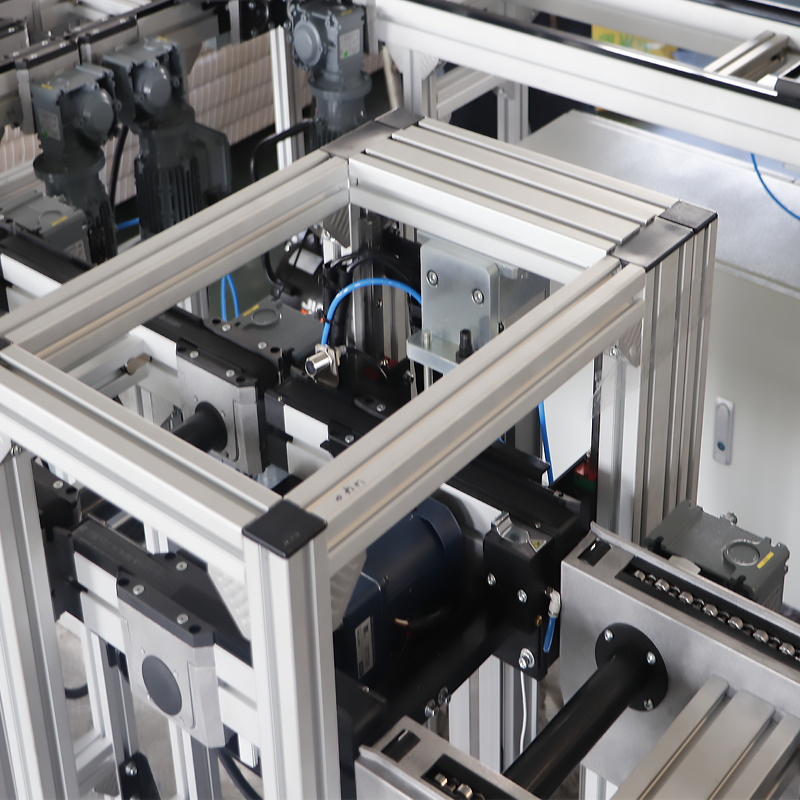

Toshine pallet conveyors are designed to easily handle and transport large, heavy, or cumbersome loads. Positioned low to the ground, these conveyors provide better control and efficiently move products using belts, slats, rollers, or chains. Both powered and unpowered Toshine pallet conveyor solutions seamlessly integrate with other pallet handling equipment, such as robotic palletizers and depalletizers, turntables, stretch wrappers, transfers, unit load ASRS, pallet dispensers, and more.

In addition to moving products from one point to another, some Toshine accumulation pallet conveyor designs include zero pressure accumulation features. Besides, these conveyors utilize photo eye-controlled networks along with AC and DC motor-controlled zones to reduce product damage and prolong the lifespan of your equipment.

Features & Benefits

- Improve Warehouse Flow: Boost overall efficiency and reduce traffic congestion.

- Minimize Labor Load Handling: Lessen the physical strain on your workforce.

- Gentle Handling: Ensure precise positioning to prevent product damage.

- Boost System Throughput: Enhance safety and ergonomics in your operations.

- Free Up Fork Truck Equipment: Allow fork truck resources to be utilized for other important tasks.

Considerations

For the most effective conveying solutions, Toshine’s team of experts will collaborate with you to explore both turnkey and custom options. Keep these details in mind:

- The details of the products being conveyed

- Type of pallet or skid

- Destination locations and whether curves or transfers are needed

- Processes, including how much starting and stopping is required, as well as product accumulation

- Environmental conditions, such as the need to handle hot or oily parts

- Available conveyance surface in your facility

Choose Toshine for reliable and efficient pallet conveyors that will enhance your material handling processes!

Types of Pallet Conveyors

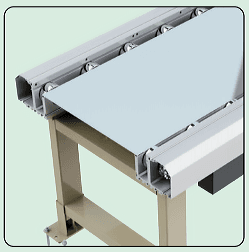

TOSH-1 Pallet Belt Conveyor: Suitable for small size areas with high cleanliness and a high level of automation in production lines. Primarily used for conveying small size and low volume products, such as in the electronics industry, small household appliances, and automotive components.

Two types of drive: end drive and center drive. Maximum load capacity: 60KG. Line body nose not over 60dB.

Conveyor speed: Max20/min

TOSH-2 Pallet Chain Conveyor: Versatile and high capacity, designed for moderate loads. Widely applicable in assembling production lines for household appliances, automobiles, and engine components.

Maximum load capacity: 2200KG, suitable for accumulation conveying. Line body noise not over 70dB.

Conveyor speed: Max20/min

TOSH-4 Pallet Chain Conveyor: Suitable for medium to large loads and long distance conveyance in production lines. Similarly used in industries like automative components, household appliances, and electronics.

Conveying medium: 12BS accumulation chain. Maximum load capacity of 2500KG. Line body noise not over 70dB.

Conveyor speed: Max20/min

TOSH-5 Pallet Roller Conveyor: Mainly employed in scenarios with heavy loads, featuring a robust structure capable of withstanding significant impact loads. Often utilized in automatic assembly production lines for automotive engines and transmissions.

Conveying medium: rollers. Total load less than 3000kg. Applicable for accumulation conveying.

Conveyor speed: 15m/min

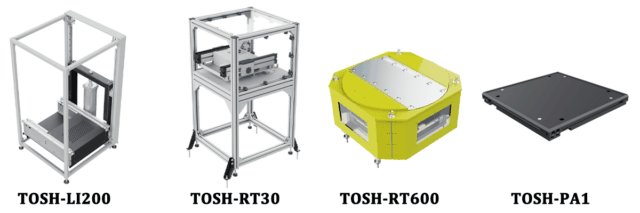

Pallet Conveying Auxiliary Euipments

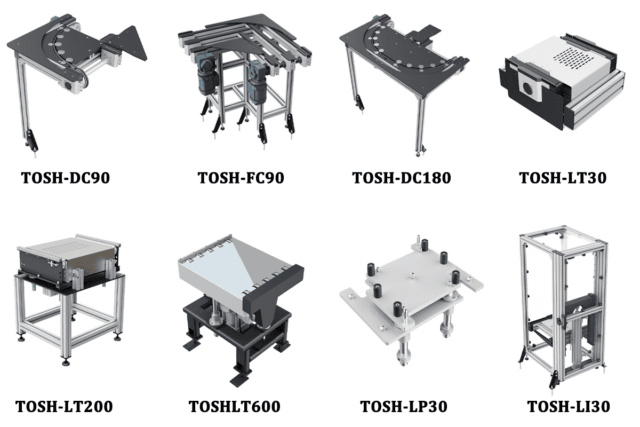

Pallet conveying auxiliary equipment serves as supplementary for pallet conveyors, especially used at junctions within production lines or locations requiring adaptablity. Besides, it comprises different mechanisms such as turning, rotating tables, lifting, top lifting, lateral shifting, and more, executing various actions to establish a closed-loop connection within the production line. All in all, corresponding auxiliary equipment for conveyors of varying loads caters to the diverse production requirements of customers.

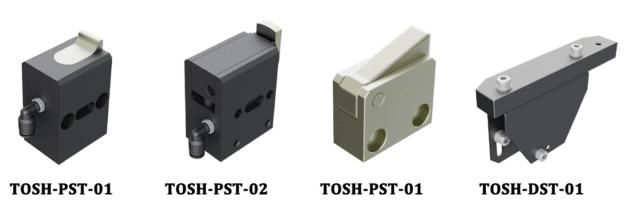

Pallet Conveyor Control Components

Pallet conveying control components are fundamental units comprising modular conveying systems. So we utilize them to alter the operational state of pallets, such as enabling passage or stopping, working collaboratively with electrical and detection systems to achieve automation and intelligence in production.