Modular automated pallet conveyor system covers timing belt conveyor, flat belt conveyor, flat top chain conveyor machines, double-speed chain conveyors, light-load and heavy-load roller conveyors. Then we can use them according to different loads and applications. And choose according to environment and size now.

Description

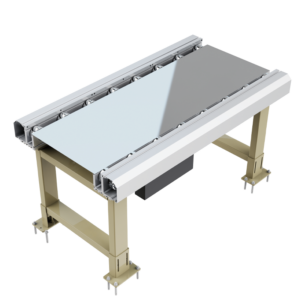

Automated Pallet Conveyor System

Automated pallet conveyor system is a type conveying equipment. And it uses pallets as carrying tools. And it places goods on pallets through conveyor belts, chains or rollers, then delivers them continuously or intermittently. Besides, pallet conveyors are widely used in warehouses, production lines, logistics centers and other places. And its aim is to achieve fast and stable transportation of goods.

What are the Features of Pallet Conveyor?

- Strong Carrying Capacity: A pallet conveyor uses standardized pallets as carrying tools. And the pallet can bear a large amount of goods. And it can meet the needs of large-volume logistics transportation.

- Strong Adaptability: A pallet conveyor can be customized according to actual needs. And it can adapt to different sizes, weights and types of goods. And whether it’s cartons, bagged materials or heavy machinery, conveyor can handle them easily.

- Efficient and Stable: A pallet conveyor uses advanced transmission system and control system. So it can ensure smooth and continuous delivery of goods Besides, and it also can reduce cargo damage and safety accidents.

- Easy to Maintain: A pallet conveyor has a simple structure. And it is easy to maintain. And also it reduces operating costs and maintenance workload.

- Energy Saving and Environmental Protection: A pallet conveyor adopts an energy-saving design. And this effectively reduces energy consumption. And also it reduces noise and dust pollution. So it suits the development trend of green logistics.

.png)

-300x300.png)