Mesh chain conveyor is designed to handle a variety of materials and products, often employed in industries. It’s equally effective in general material handling, packaging lines, or parts washing due to its ability to withstand harsh conditions.

Description

Wire Mesh ناقل الحلقات

Mesh chain conveyor refers to material handling machinery that continuously transports materials on a certain line. So we can also call it a continuous conveyor and can divide into mesh belt type and mesh chain type. Besides, conveyors can carry out horizontal, inclined and vertical conveying, and can also form spatial conveying lines. So we can generally fix.

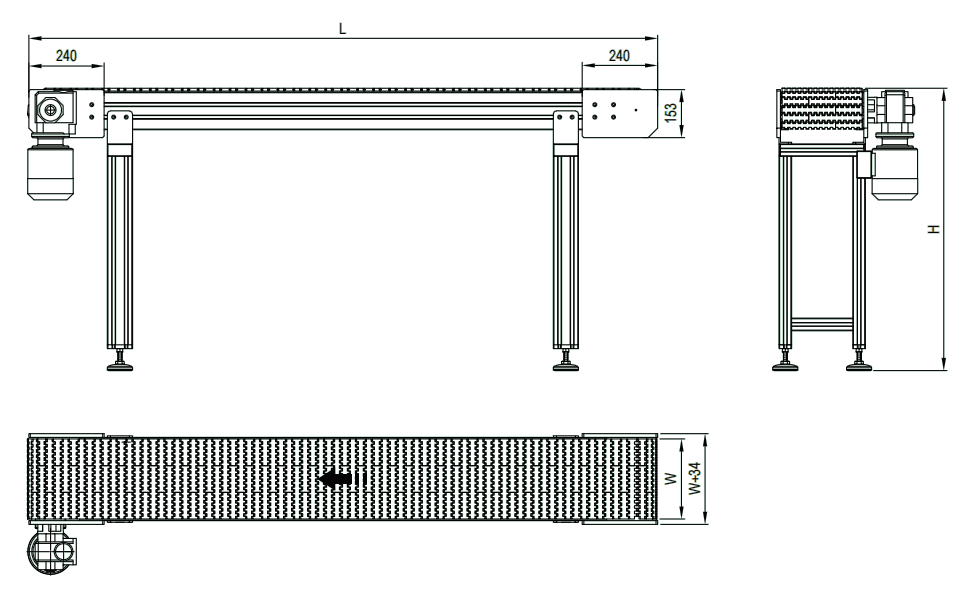

Specifications:

Model Conveyor Length L Conveyor Width W Conveyor Height H Conveyor Speed V

TOSH-CB 800~10000mm 150~1000mm As needed Max 20m/min

Product Features:

- Simple and reliable structure with low maintenance;

- Conveys medium utilizing engineering plastic materials like POM, PP, PE; water-resistant, oil-resistant, and resistant to certain corrosive substances, smooth transportation with low friction.

- The conveyor width can increase in multiples based on standard chain intervals, operating in one direction without the ability to reverse.

- T -slot aluminum profiles frame for easy accessory attachment

- Maximum load capacity of the entire unit reaches 600kg, suitable for industries such as pharmaceuticals, packaging, food, beverages, إلخ.

Dimensional Description:

Introduction:

As we know, the conveyor has a large transportation capacity, a long transportation distance. Besides those, it can also complete several process operations at the same time during the transportation process, so we use it widely. Therefore, we use mesh chain conveyor for conveying materials.

Surely, it uses stainless steel mesh belt as the carrier and is suitable for drying, dehumidification, freezing, heat treatment, إلخ. in various food industries; its material is stainless steel and has the characteristics of high temperature resistance and easy cleaning.

Conveyor application industries: food, metallurgy, electric power, coal, chemical industry, building materials, docks, grain, إلخ.

Conveyor structural forms: horizontal straight line conveying, lifting and climbing conveying, turning conveying and other forms. Accessories such as lifting baffles and side baffles can also be added to the conveyor belt to meet various process requirements.

Conveyor materials: A3 low carbon steel, 201 stainless steel, 304 stainless steel, إلخ.

Driving methods include: reduction motor drive.

Speed regulation methods include: frequency conversion speed regulation, stepless speed regulation.

Main Features:

- Large conveying capacity. The efficient conveyor allows conveying a large amount of materials in a small space, with a conveying capacity of 6m³/h~600m³/h. 2. The conveying energy consumption is low. With the help of the internal friction of the material, pushing the material is changed into pulling. Therefore, it saves 50% of energy compared with the screw conveyor.

- Sealed and safe, the fully sealed casing makes the dust drillable seamless, safe to operate and reliable in operation.

- Long service life. The normal service life of a conveyor chain made of alloy steel processed by advanced heat treatment methods is >5 years, and the life of the rollers on the chain (depending on different materials) is ≥2~3 years.

- The process layout is flexible and it can arrange on an elevated platform, on the ground or in a pit. We can use it horizontally or on a slope (≤15°). We can also install it horizontally and on a slope on the same machine. It can feed materials in and out at multiple points.

- Low cost of use, energy saving and durability, less maintenance and low cost (about 1/10 of the screw machine). So it can ensure the normal operation of the main machine to increase output, reduce consumption and improve efficiency.

Plastic Steel Mesh ناقل الحلقات

The plastic steel mesh chain conveyor enhances the capabilities of traditional belt systems. Besides, it addresses common issues such as tears, punctures, and corrosion found in belt conveyors. So it can offer a secure, swift, and easy-to-maintain method of transport for customers. Surely this conveyor system relies on modular mesh belts driven by sprockets. So it ensures the belt runs straight without snags or misalignment.

Besides, its sturdy construction allows it to resist damage from cuts and impacts, and it’s resistant to both oil and water.

In fact, this reliability means less maintenance hassle across various sectors, particularly when it comes to swapping out the mesh belt, leading to cost savings. Moreover, the belts are available in diverse materials to suit specific conveying tasks and different operational environments.

With plastic modifications, the conveyor belt accommodates temperature ranges from -10 to 120 degrees Celsius. Moreover, mesh belt sections come in pitches of 12.7, 19.05, 25.4, 27.2, 38.1, and 50.8 mm, with open area percentages ranging from 2% to 48%, meeting various application needs.

Metal Mesh Belt الناقل

Suitable for drying, dehumidification, cleaning, quick freezing and other processes in various industries

Working principle: The conveyor chain is a sleeve roller chain with a continuous bucket structure, which is used for leveling and climbing high-temperature clinker.

In a word, metal mesh belts serve as transportation platforms in conveyor systems. فضلاً عن ذلك, the propulsion for these belts is provided through the use of reduction motor drives. To adjust the velocity of the belts, methods such as variable frequency speed control and continuous speed adjustment are employed.

Besides, the supporting structure of the system is with materials that include both stainless steel and carbon steel, catering to specific durability and hygiene requirements.

Application:

1. Main features

◆ Large conveying capacity: the maximum conveying capacity can reach 526m3/h, and the maximum inclination angle can reach 60 degrees. It is resistant to high temperatures and can transport materials with temperatures below 600 degrees.

◆ The conveyor chain has a traction chain, a load-bearing chain and a forward overlapping (or reverse overlapping) hopper. It can load and unload the three parts freely.

◆ The load-bearing rollers are equipped with rolling bearings, which replace the previous sliding friction with rolling friction. The running resistance is reduced by 55%-65%, which greatly reduces the power consumption of the conveyor and has low energy consumption.

◆ The traction chain and the load-bearing chain are separate. And it simplifies the structure, reduces the cost, and facilitates installation and maintenance.

◆Long service life: The traction chain uses a long-pitch, sleeved roller chain. And all parts of the chain material are alloy steel; they have been heat-treated and are wear-resistant. The weight of the conveying part and materials is borne by the load-bearing parts. So the chain no longer bears the weight, reducing wear and tear.

◆ Various process layouts: it can be horizontal or tilted. Or we can arrange in a combination of multiple horizontal and tilted sections.

2. Applicable fields

◆ Widely used in cement, paper, sugar, chemical and other industries. Most suitable for materials such as slurry and granular materials.