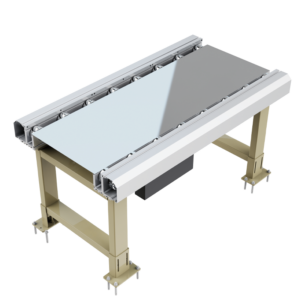

TOSH-5: Wird hauptsächlich in Szenarien mit hoher Belastung eingesetzt, Es zeichnet sich durch eine robuste Struktur aus, die erheblichen Stoßbelastungen standhält. Wird häufig in automatischen Montagelinien für Automobilmotoren und -getriebe eingesetzt. We can customize pallet conveyors based on your space and application needs.

Beschreibung

Pallet Conveyor Automation Systems

Pallet Conveyor Systems cover timing belt conveyor, flat belt conveyor, flat top chain conveyor machines, double-speed chain conveyors, light-load and heavy-load roller conveyors. And we can use them according to different loads and applications. So choose according to environment and size.

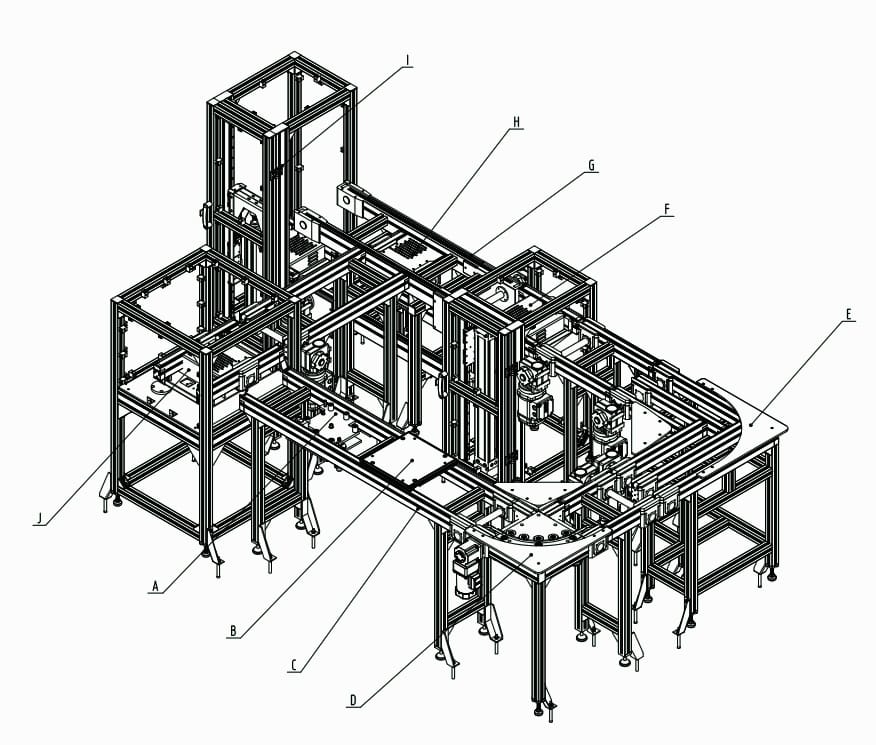

Demonstration of Modular Pallet Conveyor System Applications

A: Vertical Positioning B: Pallet C: TOSH-1 D: 90° Round Belt Turn E: 90° Forced Turn

F: Rodless Cylinder Lift G: TOSH-2 H: Lift and Transverse Shift I: Rod Cylinder Lift J: Turnable

Specifications

Model Conveyor Length L Conveying Width W Conveyor Height H Conveyor Speed V Roller spacing P

TOSH-5-GC 1000~6000mm 300~1200mm As needed 3~15m/min 160/200/250mm

Produktmerkmale

- High modularity with comprehensive supporting mechanisms, facilitating maintenance.

- Conveying medium: rollers.

- Frame of the line is made of specialized high-strength aluminum profiles, using standardized sections for connection, featuring a double-sided cantilever structure and bevel gear transmission.

- Suitable for heavy-duty pallet conveying, capable of automatic cycling and flexible control of Pallets.

- Total load ≤ 2500KG.

- Applicable for accumulation conveying.

Dimensionsbeschreibung:

Common Production Line Layouts

Surely precise and rational layout and selection play a crucial role in the birth of a production line. So It’s not just about meeting current product production needs; but it also enables adjustments to future product changes caused by market demands. Also, pallet conveyor systems, due to their modular structual characteristics, can significantly address this issue. Meanwhile also can minimize wastage and avoiding societal waste.

Requirements for Pallet Conveyor Systems

- Climate factors

- Working temperature

- Storage temperature

- Air pressure

- Relative humidity

- Chemical factors

- Physical factors

Essential Conveyor Safety Guidelines

- Observing these fundamental guidelines forms the foundation (though not the entirety) of effective safety procedures where conveyors are in operation.

- Always lock out the motor disconnect before servicing the conveyor.

- Only qualified maintenance staff are permitted to service conveyors.

- Maintain a safe distance with clothing, hands, hair, and body parts from the conveyor.

- At no time should you climb, step on, sit, or ride the conveyor.

- Do not exceed the conveyor’s specified loading capacity.

- Never remove or tamper with conveyor guards or safety devices.

- Familiarize yourself with the locations and functions of all control mechanisms for starting and stopping the conveyor.

- Ensure that controls for stopping and starting are always accessible and not blocked.

- Confirm that the area is clear of all personnel before initiating conveyor operations.

- The conveyor should be operated solely by individuals. And they need have received proper training.

- Keep the vicinity of the conveyor free from clutter that could obstruct operations.

- Immediately report any unsafe conditions to your supervisor.

Pallet Conveyor Systems Theory

In a word, pallet conveyor is a common logistics equipment. Indeed, its main principle is to drive the pallet to run on the conveyor through a motor to achieve fast, efficient and stable transportation of items. Specifically, the principle of the pallet conveyor is as follows:

- Loading of pallets: Items are usually placed on pallets, and the material and size of the pallets can be customized according to the size and weight of the items.

- Motor drive: The motor on the conveyor will drive the pallet up. And that will make it move along the running track of the conveyor.

- Running track: The running track of the pallet conveyor is usually a closed circular track. Außerdem, that track can rotate around the logistics center to facilitate the picking and handling of items.

- Control system: The operation of the pallet conveyor can be adjusted through the control system, and it can control parameters such as conveying speed and stop position. Then it will achieve precise positioning and delivery of items.

We use pallet conveyors mainly in factories, warehouses, logistics centers and other places. Because they can achieve efficient logistics transportation and item storage. Gleichzeitig, the pallet conveyor has the characteristics of automation and intelligence, too. So we can customize and optimize according to different production and logistics needs.

Otherwise, pallet conveyors are designed for longevity and durability. Built with high-quality materials and precision engineering, they can withstand the demands of heavy-duty industrial environments, ensuring reliable performance and minimal downtime.

Get a Quote Now!

In a word, by choosing us, you’re not just purchasing equipment; but you’re also gaining a reliable partner committed to your success, which, in turn, translates to enhanced productivity and profitability. Certainly it is delighting to make a solution for everyone. Obviously, we are ready for you here.

So come and get a contact! Insgesamt, we hope to work with you in the near future. Waiting for you!