Our pallet conveyors are designed for efficient horizontal transport of palletized goods. Built from durable aluminum and stainless steel, these conveyors ensure reliable performance with minimal noise and low maintenance.

The modular design allows for easy customization to fit your workflow, while precision positioning units guarantee accurate placement of workpiece carriers. Ideal for various industries, our pallet conveyors enhance operational efficiency and streamline logistics processes.

Beschreibung

Toshine Modular Workpiece Pallet Förderer System

Palettenfördersystem: Efficient Transport of Pallets and Workpiece Carriers

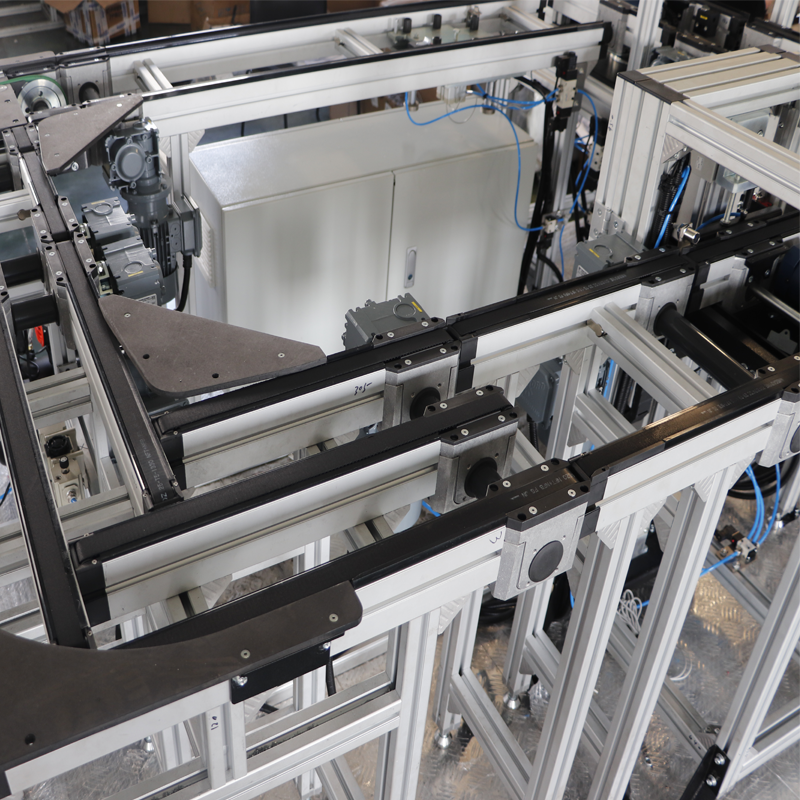

Pallet conveyors and workpiece carrier conveyors make it easy to move your workpieces in a controlled manner. This system can handle products gently, using flexible conveyors and workpiece carriers (pallets) to ensure precise positioning during transport.

Palette Conveyors from Modular Automation

Our pallet conveyor systems are made from aluminum and stainless steel. So that will ensure a robust and dependable foundation for operation. These systems can transport product carriers or pallets of various sizes, accommodating loads of up to 60 kilograms.

Our pallet conveyors are versatile and suitable for a range of applications across multiple industries. It is including automotive, electrical, mechanical machining, Arzneimittel, medical technology, and optics. They transport workpieces placed on the pallets through different production processes.

With the assistance of stoppers and fixing or positioning stations, workpieces are positioned accurately, allowing for tasks such as removal, machining, or assembly with handling axes or robots. We provide both standardized and customized workpiece carriers and pallets, as well as standardized operational functions.

Modular Layout – Standardized Functions and Processes

The basic pallet is standard and serves as the transport element of the system. Key processes such as stopping, buffering, fixing, precise positioning, diverting, and merging are also standard. This method enables rapid and cost-efficient integration into your current operations.

The modular design of our systems permits the creation of tailored and efficient line layouts that enhance production processes. Zusätzlich, this modular design offers a great deal of flexibility, allowing for easy expansion, modification, and adaptation of the system to suit your changing needs.

Workpiece carriers-pallets

Pallets and workpiece carriers from Modular Automation protect your products while ensuring precise positioning. The transport process using the pallet conveyor is notably quiet, with low power consumption and minimal maintenance requirements.

Stoppers for workpiece carriers

Stoppers on the pallet conveyors help distribute products evenly. Sensors detect the pallets and halt them at designated positions, allowing the conveyor chain to continue running smoothly.

Positioning unit for workpiece carriers

The positioning unit guarantees accurate placement of the workpiece carrier. It lifts the pallet off the conveyor chain and positions it precisely for specific work processes, such as those involving handling axes or robots. In der Zwischenzeit, the chain keeps moving to transport other workpiece carriers to the next stage of production.

Chain Conveyor System Components at a Glance

Unsure which system is best for your product? Here, you will find an overview of all system sizes, including technical specifications and relevant components. Our offerings include chains ranging from 44 mm to 103 mm in width, suitable for products weighing up to 20 kg.

Principle of Pallet Conveyors

We design a pallet conveyor to transport palletized goods horizontally. Its working principle involves several key aspects:

Erste, the pallet conveyor uses a motor to drive a roller or chain transmission device. It starts the movement of the conveyor chain or rollers. The selection of the transmission device is based on the specific requirements of the workplace and the type of conveyor.

Second, once the conveyor chain or rollers begin to rotate, palletized goods placed on the conveyor are pushed forward by the forces of friction and gravity. Typically, people install guide devices on the conveyor. That will ensure that the goods travel along the designated transport path, preventing any deviation or risk of falling off.

Zusätzlich, for palletized goods that need to be sorted or merged, pallet conveyors are often equipped with sorting or merging devices. The sorting device directs goods based on their destination or predefined criteria, facilitating subsequent logistics operations. In der Zwischenzeit, the merging device consolidates goods from multiple conveyor lines into one, enhancing logistics efficiency and optimizing space usage.

Endlich, at the end of the conveyor, there are usually unloading stations. Or conveyor belts set up to offload the goods or transport them to subsequent work areas. We can tailor these devices to specific requirements. So that will ensure the safe and efficient handling of products.

Abschließend

Zusammenfassend, the pallet conveyor’s working principle involves starting the conveyor chain or rollers via a motor, pushing goods forward with friction and gravity, using guide devices to maintain correct alignment, employing sorting and merging devices for efficient logistics, and finally unloading or delivering goods through designated equipment. This principle is widely applicable in warehousing, Logistik, manufacturing, and other sectors to enhance logistics efficiency and reduce labor costs.