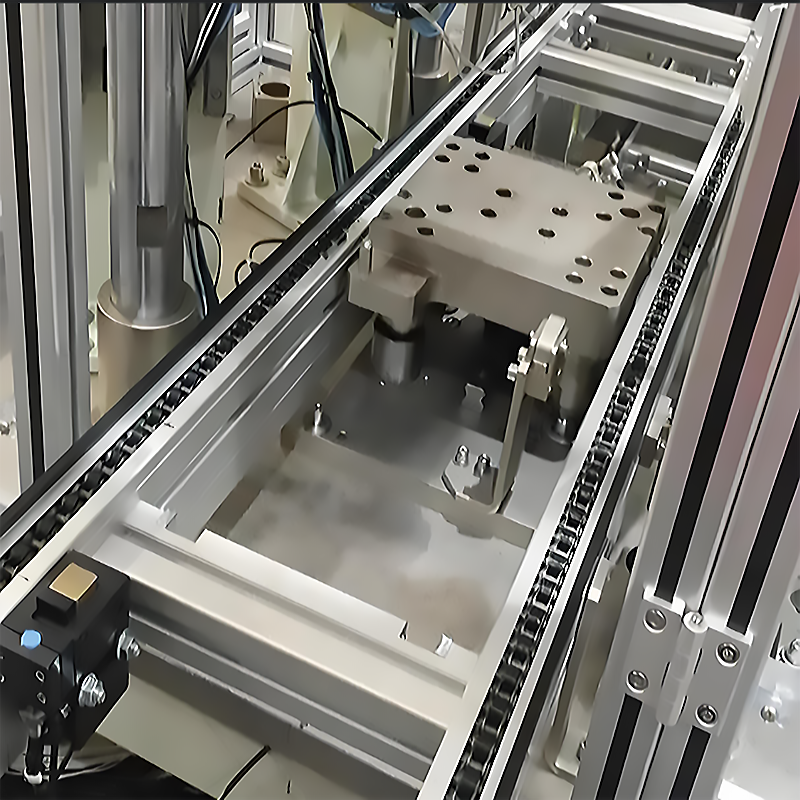

This pallet chain conveyor system is customizable to fit various lengths and configurations, making it versatile for different applications such as manufacturing, Lagerung, and distribution. With easy integration into existing setups and essential safety features, the Pallet Chain Conveyor enhances operational efficiency while maintaining a safe working environment. Upgrade your material handling process with this dependable and powerful conveyor solution

Beschreibung

Toshine Pallet Chain Förderer System

Structure and Working Principle of Double Plus Conveyor Chain

Definition of Double Plus Chain:

Double plus conveyor chains, also known as double plus chains, differential chains, or differential conveyor chains, are similar to roller chains used in material transport.

How It Works:

In a double plus conveyor system, the chain moves at a constant speed. However, the pallets and workpieces on the chain can move at different speeds as required by the user. Operators can stop the pallets at specific points for various assembly tasks and then move them forward again. This system is also called a pitch conveyor chain or free pitch conveyor chain.

Key Features:

The speed of the pallets differs from the speed of the chain itself. Double plus conveyor systems are common in industrial automation and are also known as double plus assembly lines or differential chain assembly lines.

Advantages of Double Plus Chains:

- High Efficiency: The chain runs at a low speed, while the pallets and materials can move at speeds much higher than the chain, ensuring high transport efficiency. This also keeps the chain stable, reduces noise, minimizes wear, and extends its lifespan.

- Controlled Movement: The friction between the pallets and rollers allows for controlled movement. When the chain moves at its original speed, the pallets can stop at specific points, controlling the transport rhythm. The chain is also protected by the rolling friction.

- Lightweight and Durable: The chain is lighter and more durable compared to roller chains with horizontal wings and slats. The entire system is lightweight and starts quickly.

Applications:

In a word, double plus conveyor systems are mainly used for material transport in assembly and processing lines. In der Zwischenzeit, the system makes the double plus chain move pallets quickly. Stoppers can halt the pallets at specific workstations, or commands can control accumulation, transfer, and rotation functions.

People rarely use these systems alone and are often part of a horizontal or vertical circulation system with specialized machines like lifting transfer machines and rotating machines. The system uses specially treated extruded aluminum alloy profiles as guides, ensuring stability and durability for mass production. Its flexible and diverse design makes it multifunctional.

Common Uses:

Double plus conveyor lines are ideal for small to medium-scale assembly, testing, aging, and transport. They can be equipped with fixtures on the pallets to meet assembly needs. We use them widely in the assembly, testing, and debugging of small to medium-sized appliances, such as computer monitors, mainframes, laptops, air conditioners, TVs, microwaves, printers, fax machines, and audio amplifiers.

Technical Parameters:

– Width: 250-900mm, customizable

– Height: Typically 750mm, range 500-1000mm

– Length: Single drive, customizable

– Speed: 2-20 meters per minute

– Chain Types: Equal-speed double-pitch roller chain and differential-speed chain (2.5x and 3x speeds)

– Pallet Types: Steel, engineering plastic, wood

– Frame Material: Aluminum alloy, carbon steel

– Electrical Setup: Conductive wheels in the line and conductive strips on the pallets for powered transport and testing

– Power Supply: Single-phase 220V or three-phase 380V, 50Hz

This system’s flexibility and multifunctionality make it a crucial part of industrial automation production lines.

Advantages:

- Swift Material Movement: The double-speed chain conveyor line incorporates an innovative chain transmission system that operates at high speeds, ensuring fast and efficient material transport. It excels in completing numerous logistics tasks quickly, enhancing production efficiency significantly.

- Dependable Performance: Utilizing sturdy chains and transport modules, the double-speed chain conveyor line guarantees stable and reliable material transmission. It maintains consistency and reliability during prolonged operation, reducing the risk of breakdowns and downtimes. Thus it will ensure uninterrupted production line operation.

- Precise Material Positioning: Equipped with an advanced positioning system, the double-speed chain conveyor line can precisely control the material’s position and transmission path. This precision allows for accurate material positioning and fixed-point transmission, ensuring materials reach their destination with accuracy and punctuality.

- Versatile Adaptability: The double-speed chain conveyor line offers flexible adjustment and configuration options based on various material characteristics and production requirements. It can adapt to different conveying scenarios. It is including straight-line, curve, rising, and falling transmissions, catering to a wide range of logistics environments.

- Intelligent Control: Featuring an intelligent control system, the double-speed chain conveyor line enables automated material transmission and operational management. It can be seamlessly integrated with other equipment or systems to optimize the overall production process and facilitate intelligent management of operations.

Improve Your Efficency Now

So enhance your material handling efficiency and ensure seamless pallet transport with our Pallet Chain Conveyor. Its robust design, high load capacity, and versatile configuration options make it the perfect solution for any industrial setting. Don’t miss out on the opportunity to optimize your operations and boost productivity. Contact us today to learn more and take the first step towards a more efficient and reliable material handling process!