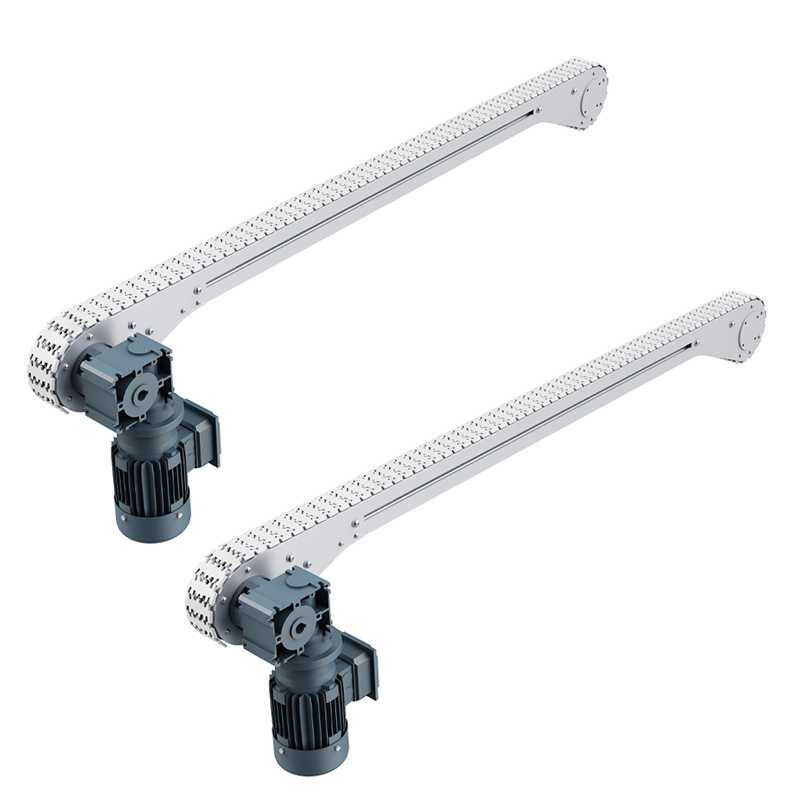

Flexible Chain Conveyors are a versatile, space-saving solution for transporting products efficiently through complex routes. Its bendable chain links easily adapt to twists, turns, and elevation changes within tight spaces. Ideal for diverse industries, this conveyor optimizes workflow with minimal maintenance.

Priskribo

Flexible Ĉena Transportilo Manufacturer

Flexible chain conveyors are adept at handling heavy loads and accommodating long-haul transfers, providing both linear and curvilinear conveying solutions. The chain width is customizable, crafted to meet specific client requirements or to suit particular situational demands.

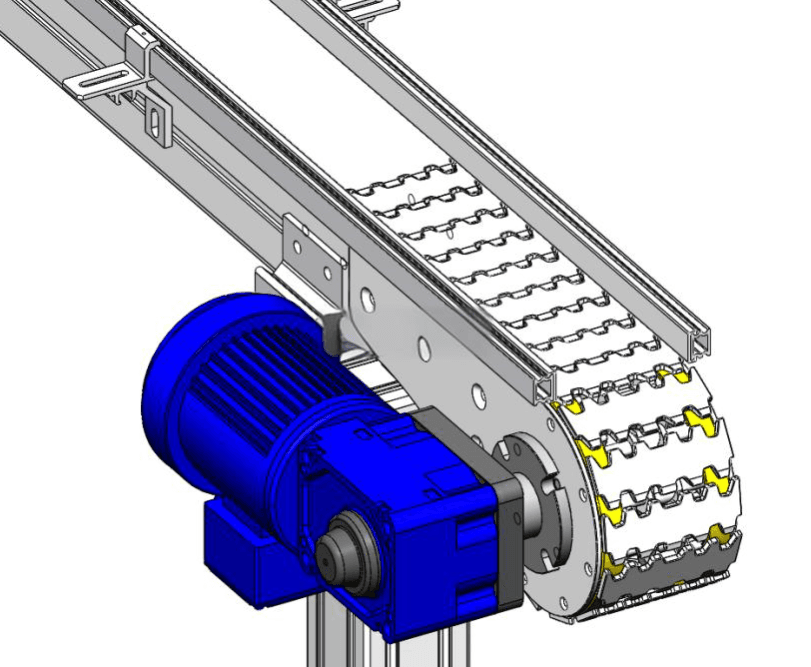

Featuring both straight and curved chain options, these conveyors use carbon steel with a spray coating or galvanization for general applications. While the food and cleanroom industries benefit from stainless steel construction due to hygiene standards.

Commonly we can find it in the assembly lines and transport processes of industries. Such as diesel engines, home appliances, food, automotive, and motorcycles. Flexible chain conveyors (also referred to by the same name) epitomize modern design with their smart appearance, ease of setup. And consistent conformity to standardized configurations. They operate cleanly, with no pollution footprint.

Renowned for their role in improving operational hygiene, flexible chain conveyors serve sectors with stringent cleanliness mandates. It is including the food, beverage, paper product, dairy, cosmetic, and tobacco industries. Capable of automating the seamless flow of materials, these conveyors are integral to distribution, packing. And the highly efficient specialization of labor within production enterprises.

The flexible chain conveyors adapt to various product types with different conveyance methods like clamping, hanging, dragging, and pushing. Their functionality can be tailored to merge, divide, cluster. And sort items within the production line, culminating in a transportation system perfectly allied to the product’s process requirements.

As a lightweight, modular conveyance solution, the flexible chain conveyor utilizes an aluminum alloy frame alongside a plastic steel conveyor chain. Cetere, it results in an intelligent, aesthetically pleasing, and standardized structure. It’s designed for rapid installation and provides a stable, compact, and silent operation that’s free from any environmental contaminants.

Wide Application of Flexible Ĉenaj Transportiloj in the Cosmetics Industry

Flexible chain conveyors have found a prominent place within the dynamic cosmetics industry.. And it caters to its diverse needs which span personal care, beauty treatments, and fragrances. As the quest for aesthetic enhancement escalates, so too does the cosmetics industry grow. And flexible chain conveyors play an increasingly vital role in this sector’s expansion.

By design, flexible chain conveyors consist of interlinked chains and traction elements. And they offer the benefits of a straightforward construction, reliable operation, and low-maintenance demands. Within the realm of cosmetics, we can employ these conveyors commonly to transport a varied array of packaged products—ranging from bottles and cans to bags—effortlessly handling items like shampoos, body washes, and skin care treatments.

But the true merit of flexible chain conveyors is their superb flexibility. And also their versatile adaptation to the cosmetics industry’s expansive product range. Each product may require unique packaging styles and specific methods of conveyance. Moreover, the conveyors can quickly pivot to different packaging needs by simply switching out the traction chains and components, thus streamlining production flows.

Moreover, they guarantee a stable transport environment, ensuring that cosmetics products remain pristine, free from damage, or risk of contamination.

Features in Cosmetics Industry

Features in Cosmetics Industry

Delving deeper into the characteristics in the context of the cosmetics industry, flexible chain conveyors are defined by:

1. Hygiene: These conveyors are designed with cleanliness in mind, using materials that satisfy food-grade standards to maintain the purity and integrity of cosmetic products throughout the conveyance journey.

2. Efficiency: The movement speed of the flexible chain conveyor can be tailored to the production demands, offering a versatile solution to optimize operational throughput.

3. Reliability: Crafted from high-quality materials, the flexibility of chains and traction elements within the conveyor provides stable, reliable function, which in turn minimizes potential downtimes.

4. Safety: Safety is a paramount factor in the design of flexible chain conveyors, and they are fitted with protective devices that can halt operations in case of a malfunction to prevent accidents.

En resumo, implementing flexible chain conveyors in the cosmetics industry serves to bolster production efficiency, guarantee product integrity, reduce overhead costs, and enhance overall market competitiveness. As global beauty standards continue to evolve, and the cosmetics industry scales new heights, the reliance on sophisticated solutions like flexible chain conveyors will only deepen. So that makes their use even more widespread.

The Importance of Conveyors

A conveyor is a mechanical apparatus, we can design for the transference of materials. So It serves the primary function of shifting goods from one location to another. Cetere, it is an integral tool in the realms of industrial manufacturing and logistics.

Outlined below are the core purposes of conveyors:

- Transportation of Materials: Conveyors facilitate the movement of diverse materials, for instance, channeling raw materials from storage areas to the manufacturing line or ferrying completed goods to the packing area.

- Streamlining Production: Integrating seamlessly with various automation tools, conveyors enable the automatic transfer, unloading, handling. And sorting of materials, thus augmenting production rates and enhancing the caliber of products.

- Labor Reduction: By substituting manual material movement, conveyors alleviate the manual workload of employees and contribute to labor cost savings.

- Efficiency Enhancement: With adjustable speeds and capacities, conveyors deliver seamless, uninterrupted material flow, amplifying overall production efficiency.

- Cost Minimization: Implementing conveyor systems cuts down expenses related to material handling, reduces the buildup of materials. And saves on space, facilitating more effective production management.

- Versatile Adaptation: Conveyors are adept at adjusting to varied material traits and production conditions, including extreme temperatures, dust mitigation. And safe operation in potentially explosive environments, catering to an array of manufacturing requirements.

In conclusion, conveyors hold a vital place in industrial production and logistics, bolstering efficiency, slashing costs, conserving labor, elevating product standards, and exhibiting tremendous flexibility to suit diverse operational demands.