aluminum profile ladders are a superior choice for anyone seeking a reliable, safe, and long-lasting solution to elevation challenges. They are a testament to modern design and engineering, providing a practical and economical option for reaching new heights.

Priskribo

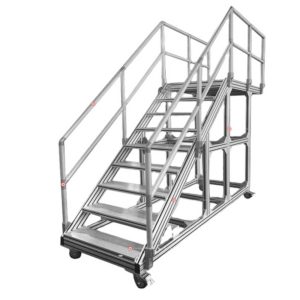

Ŝtuparo & Platforms Made from Aluminium Profiles

Aluminum profile ladders play an increasingly integral role in our daily lives, vital for accessing elevated areas and for home embellishment. Available in diverse forms such as aluminum alloy, stainless steel, and glass, with aluminum alloy dominating the market. Aluminum profile ladders offer enhanced safety over their wooden counterparts and boast effortless handling thanks to their light construction.

Constructed from robust aluminum alloy profiles, these aluminum profile ladders are lightweight for ease of transportation. They incorporate cutting-edge square tube extrusion riveting technology for superior safety and we equip it with sturdy, slip-resistant feet. Aluminum profile ladders boast several advantages over traditional bamboo and wooden ladders. Including their lighter weight, stronger material, and resistance to cracking and warping, making them a preferred choice in a variety of industrial settings.

Typically, we produce these profiles by using 6063T6 / T5 aluminum alloy through a hot extrusion process. Before using a ladder, take the following steps:

- Verify the tightness of all rivets, bolts, nuts, and other moving parts to ensure the step columns. And rungs are secure and that the extension springs and hinges are functioning properly.

- Ensure the ladder is free from slippery materials like grease, oil, wet paint, mud, or snow.

- The shoes of the individual using the ladder should be clean and free from leather soles, which could potentially slip.

Safety considerations during aluminum profile ladders use include:

Safety considerations during aluminum profile ladders use include:

- Do not use a ladder if you are overtired, under the influence of medications, alcohol. Or if you have any physical restrictions.

- Place the ladder on a stable, solid surface, avoiding placement on ice, snow. Or any slippery surface not equipped with anti-slip fixtures.

- Do not exceed the maximum load capacity indicated for the ladder.

- Avoid using ladders in strong wind conditions.

- Since metal ladders can conduct electricity, be cautious and avoid use near live electrical environments.

- Always climb facing the ladder, gripping with both hands, and maintaining the body’s center of gravity between the ladder columns.

- Do not stand on the ladder’s steps within one meter from the top; always maintain at least a one-meter safety height and do not climb beyond the topmost support point.

- Refrain from reaching overhead while working on the ladder to prevent loss of balance and potential hazards. 9. It is important not to traverse directly from one side of the ladder to the other.

Care and Service

- Periodically clean the aluminum profile ladders to protect them from potential chemical corrosion and routinely inspect the connecting components, lubricating them as needed.

- In cases where the ladder’s material is distorted or damaged, or if the connecting elements aren’t functioning correctly, reach out to the manufacturer for expert repair services.

- Extreme weather can shorten the lifespan of a ladder. Typically, a ladder’s life expectancy is around two years when used indoors and one year when used outdoors.

Product features and applications of aluminum profile ladders

Introduction

Mainly used in aerospace, high-speed rail maintenance, industrial equipment maintenance, ktp.

The overall frame structure material is aluminum profiles, with a load-bearing capacity of 2000-3000 kg. With different pedals, we can use it in different places.

The main materials used for the aluminum profile ladders are:

Aluminum profiles, and strong aluminum profile handrails, supplemented by reinforced support, make the aluminum profile ladder safe and stable, so that climbing operations are as easy as walking on flat ground.

Function:

1. As a carrying tool for material handling and turnover

2. As an auxiliary tool for climbing and picking up goods.

Safety performance:

We equip one side of the aluminum profile ladders with steps (with handrails next to the steps) for users to climb onto the platform. And we equip the other three sides of the platform with guardrails to ensure the safety of the operator.

The platform working surface is generally large enough to accommodate 1-2 people standing, turning, and moving. Users can complete actions such as stacking and picking up items from high places. Such as shelves on the platform of the aluminum profile ladder.

Krome, we can equip the aluminum climbing platform with casters, which users can push, pull, turn and move, which is convenient and fast. We equip the front casters with wheel brakes. After braking, we can fix the climbing ladder and cannot move it, and users can climb safely and confidently.

Avantaĝoj

The aluminum profile ladders can design the platform frame according to the on-site environment, with strong plasticity. So it has strong load-bearing capacity, safe and stable; and we can install it in a modular manner, making on-site disassembly and assembly very convenient.

Cetere, it also has the advantages of environmental protection and pollution-free, solid structure, beautiful appearance, corrosion resistance, rust-free, and lifetime maintenance-free, which is suitable for various climbing operation environments.

Looking ahead, countries leading in aluminum profile production, such as mine, are poised to steer towards sophisticated and varied aluminum profile product ranges, with a corresponding uplift in product standards. Not only are these profiles extensively employed in their principal sectors of construction and industry. But their applications are also expected to span an even wider array of fields.

It’s envisaged that, with ongoing innovation in technology and a bolstered commitment to product research and development by aluminum profile companies, the assortment of aluminum profile products in our nation will broaden, enhancing their presence in the construction, electronics, and aerospace industries, among others.