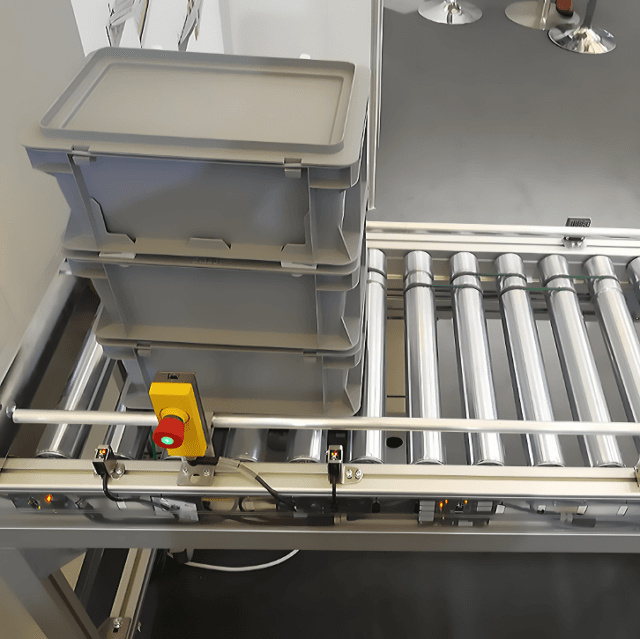

Safety is paramount, and the gravity roller conveyor is equipped with built-in safety features to ensure a secure working environment. From strategically placed guardrails to emergency stop mechanisms, every aspect of the conveyor system is designed to protect your workforce and prevent accidents.

Priskribo

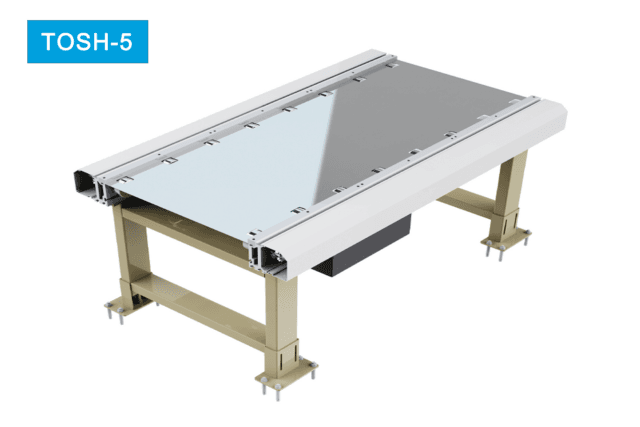

Toshine Gravity Roller Conveyors

Gravity roller conveyor is a common material conveying equipment, suitable for material conveying in various industries. Meanwhile, it uses the roller as the driving device, uses the gravity of the material. And transfers the material from one location to another with the assistance of the roller.

Application field of gravity roller conveyor

1. Application Scenario of Gravity Rultransportilo

Gravity roller conveyor is a mechanical principle based on deadweight, which realizes material conveying through natural downhill. It does not require external power drive and has the advantages of simplicity, energy saving and reliability. Therefore, people use it widely in the following scenarios:

- Warehousing and logistics field: used in large warehouses, logistics centers, container yards and other logistics facilities. That can realize fast and efficient cargo sorting and transportation.

- Manufacturing field: used for carrying, transportation, transfer and other processes on the production line. And that can realize automated production and material transportation.

- Waste recycling field: used for waste sorting, recycling, processing and other processes. And it can realize a certain degree of automated operation.

2. Advantages of Gravity Roller Conveyor

Compared with traditional mechanical conveying methods, gravity roller conveyor has the following advantages:

- Ŝparado de energio kaj mediprotekto: no external energy consumption is required, reducing environmental pollution and energy consumption.

- Low maintenance cost: The roller conveyor has a simple structure and low maintenance cost.

- Space saving: no motor and other equipment are required, and the floor space is small.

- High safety: It has overload self-protection function, simple operation, and high reliability.

In short, gravity roller conveyor is a convenient, efficient and environmentally friendly conveying equipment. So it is suitable for multiple industries. Therefore, it plays an important role in logistics, manufacturing and other fields.

How to Select the Rollers?

When selecting the rollers for your aluminum profile roller conveyor, it’s important to consider several factors to ensure optimal performance and efficiency of the conveyor system.

Firstly, consider the material of the roller drum. Depending on your specific requirements, you can choose from various materials such as carbon steel (galvanized, chrome-plated, nickel-plated), cast rubber, stainless steel, or steel plastic steel. In industries like food processing, stainless steel rollers are ideal for hygiene and durability.

Next, think about the surface treatment of the roller body. People can treat carbon steel rollers with options like spraying or plastic spraying. While stainless steel rollers can be polished to a mirror finish or treated with matte, sandblasting, or brushing.

Others You Need Notice

If speed control is necessary, opt for variable frequency speed regulation or a stepless speed reduction motor to meet your operational needs.

The diameter of the roller is crucial as it not only impacts conveyor performance but also influences its longevity. Therefore, choosing the right drum diameter can enhance conveying efficiency.

When it comes to roller width and spacing, match the roller width to the outer dimensions of the objects to prevent contact with the frame. The spacing between rollers should be based on the length and weight of the objects to ensure adequate support.

For gravity conveyors using unpowered rollers, determining the self-propelled slope is essential. People should adjust the slope according to the condition, material, and weight of the objects. It’s recommended to conduct tests to determine the optimal slope.

Lastly, notice any special needs for the conveyor system. The height of the gravity roller conveyor roller’s top surface should be lower than the side height of the frame. If any need, adjust the side height of the frame to align with the roller height. Additional features like side baffles, gardistoj, or guardrails, we can add based on specific operational needs.

Thank You for Choosing TOSHINE

In closing, the world of industrial automation is always changing. And conveyor systems play a big role in making work easier and more efficient. As someone who knows a lot about conveyor systems and industrial automation, I’m here to help you improve how you handle materials.

Let’s work together to create conveyor solutions that fit your needs, whether you need help with moving pallets, transporting materials, or setting up assembly lines. With my knowledge in industrial conveyors, stairs, platformoj, enclosures, gardistoj, and aluminum workbenches, I can guide you to find the right solutions for your business.

Together, we can make your operations run smoother, save time, and help your business succeed in the world of industrial automation. Start making changes today to boost your productivity. Kontaktu, and let’s begin this journey towards better automation together.

Versatility is a key feature of the Gravity Roller Conveyor, allowing it to adapt to different material handling tasks. Whether you need to transport boxes, cartons, totes, or other goods, this conveyor system can efficiently move them along the production line or warehouse floor. Cetere, that can reduce manual handling and increasing operational efficiency.