Améliorez l'efficacité de la production grâce aux lignes de convoyeurs à chaîne

In industrial production, les lignes logistiques en chaîne à double vitesse sont des outils essentiels qui offrent des avantages remarquables: haute efficacité de transport, forte capacité portante, adaptabilité aux environnements difficiles, installation et entretien faciles, positionnement précis, rentabilité, et une sécurité robuste. Ces fonctionnalités permettent aux entreprises de mettre en place des processus de production efficaces et rationalisés.

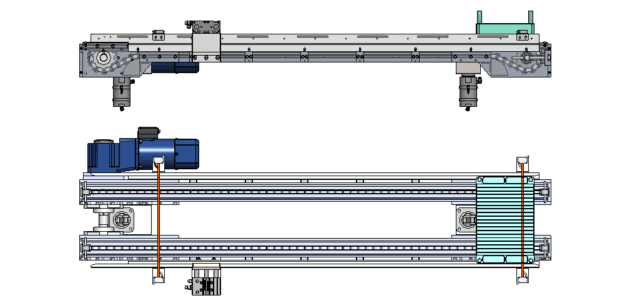

Constructing a double-speed chain logistics line is straightforward and time-saving. The primary components include two double-speed chains, matching sprockets, and profiles. However, for first-time users, the main challenge often lies in properly fixing and tensioning both ends of the chain. Here’s a step-by-step guide to help you get started:

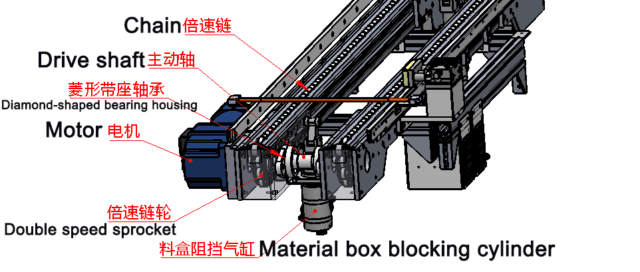

Assembly of the Drive Mechanism

Position the double-speed sprockets centrally between the two machined parts (one sprocket per side).

Secure the machined parts to the left and right sides of the chain profile.

Smoothly place the double-speed chains over the sprockets for a perfect fit.

Attach diamond-shaped seated bearings to the machined parts and insert the drive shaft through the bearings and sprockets, connecting the left and right sprockets.

Enfin, connect the motor to one end of the drive shaft to power the mechanism.

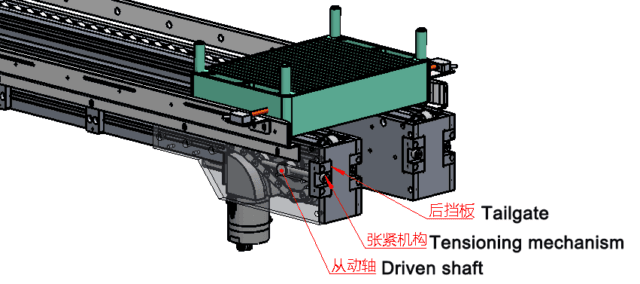

Tensioning the Chain

On the driven shaft side, drill two threaded holes and install a long screw through the rear baffle.

Link the screw to the driven shaft and apply slight torque. This ensures the chain is properly tensioned, allowing smooth and efficient operation.

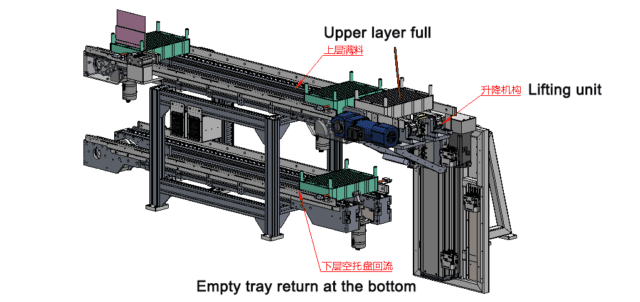

Enhancing Efficiency with Dual-Layer Design

For higher productivity, construct the logistics line as a dual-layer system. Use profiles to connect the upper and lower layers securely.

Install a small elevator mechanism at the unloading end to facilitate upper-layer material handling and lower-layer pallet return flow.

Key Material Specifications:

Speed-Regulating Motor: Model 200YF03-100YF (with brake)

Speed Regulator: Model 200GV22-100GF20RC

Seated Bearing: Model T-BDU205

Double-Speed Chain: Model VMW02-BS25-C208A-122 (adjustable to your needs)

Double-Speed Sprocket: Model VLW02-BS25-C208A-10-D25

Return Guide Rail: Model VMH01-BS25-C208A

By following these steps and specifications, you can build a reliable and efficient double-speed chain logistics line tailored to your production needs.

Are you looking for transporteurs de chaîne, or belt conveyors, or other automation products? Come and contact Toshine, we are always here.