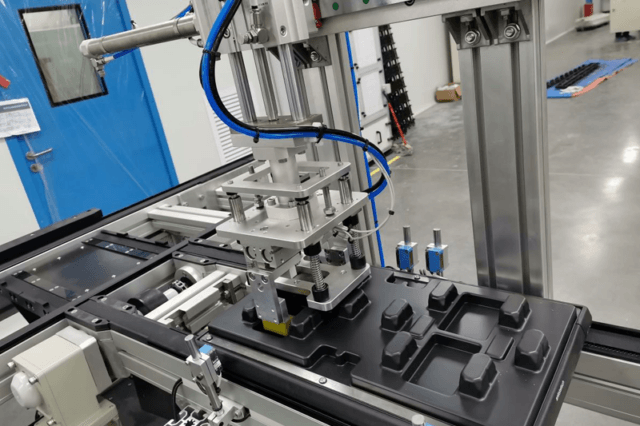

Pallet conveyors come with advanced features such as adjustable speed controls, allowing for precise handling and pacing of goods. Compatible with various pallet sizes and weights, they ensure smooth transportation from one point to another, reducing manual labor and the risk of workplace injury.

Description

Heavy Duty Convoyeurs de palettes for Sale

The pallet conveyors mode is including various forms of automatic conveyors, including roller, chaîne, roller, plate, lifting platform and other forms. Different enterprises can choose to adopt different forms of conveyor modes according to their own needs for automated transportation.

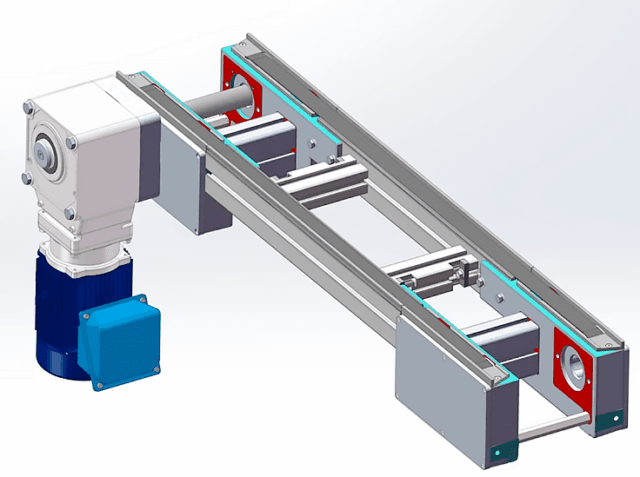

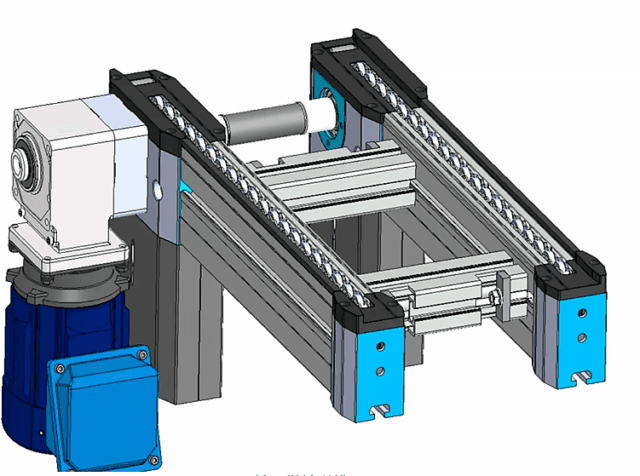

Generally speaking, in the automated warehouse system, in order to meet the system’s requirements for the transportation of pallet goods, more pallet automated conveying systems composed of roller or chain conveyors with higher transportation efficiency are selected.

The conveyor mode can realize continuous transportation, so that people can carry out the loading operation of the pallet without stopping. And people can handle the material caching function conveniently on the conveyor line, without the need for interruption of transportation due to empty load.

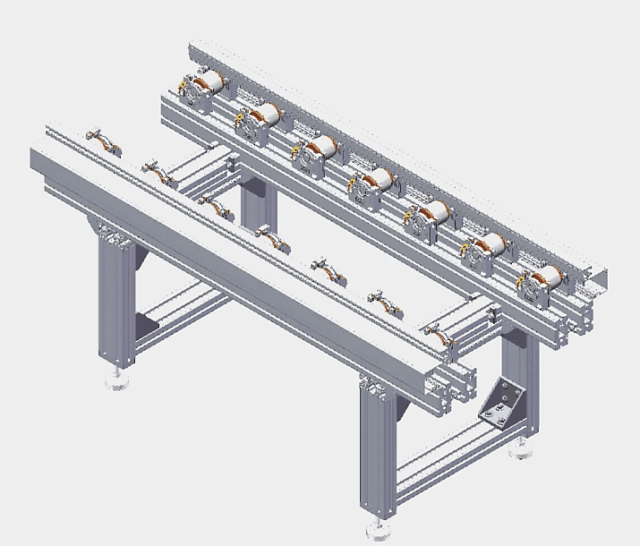

En outre, we can extend the length of a single conveyor. And a long-distance conveyor line composed of multiple conveyors is also more convenient for enterprises. And that will realize programmed control and automated operation.

The conveyor mode is an automated pallet conveying system with various automatic conveyors. Pallet conveyors are available in various forms, such as roller conveyors, transporteurs de chaîne, convoyeurs à rouleaux, plate conveyors, and lifting platforms. In automated warehouse systems, in order to meet the system’s capacity requirements for pallet cargo, roller conveyors with higher transportation efficiency and chain conveyors are generally used to form pallet automated conveying systems.

According to the needs of automatic conveying, we can use a single type of conveyor to form a pallet automated conveying system with specific functions. Or several types of conveyors can be mixed to form a pallet automated conveying system with specific functions as we need.

Advantages of Convoyeur Mode:

- Continuous conveying mode with large conveying capacity. It can be conveyed uninterruptedly, and its loading and unloading are carried out without stopping during the conveying process. There is no need to experience no load and cause conveying interruptions. En même temps, since it is not frequently started and braked, a higher conveying speed can be used.

- The structure is relatively simple. It has a single action, a compact structure, a light weight, a low cost, a uniform load, a stable speed. And the power consumed during work is generally small and does not change much.

- The length of a single conveyor can be extended, and people can form a long-distance conveying line by multiple conveyors. That is convenient for programmable control and automated operation.

- People can handle the material buffer function easily on the conveyor line.

Disadvantages of the conveyor mode: poor versatility, we must arrange the conveyor according to the entire conveyor line. There are many conveying equipment, the conveying path is complex, it belongs to the category of rigid transportation. It is not suitable to change the transportation route.

The cost is higher than the reciprocating shuttle, usually in order to meet the transportation capacity needs, we require many equipments to combine into the warehouse access channel, and the floor space is too large.

Types de convoyeurs de palettes

Pallet conveyors are mainly including four types: timing belt conveyors, flat belt conveyors, roller chain conveyors (single-speed chain), and accumulation rollers. The biggest difference from traditional conveyors is that the carrier they convey is not directly conveying products, but modular pallets with positioning functions. Donc, pallet conveyors, we also call modular conveyor belts in the industry.

Timing belt conveyor, Conveying limit: 60kg, unit length load limit: 1kg/cm, the maximum length cannot exceed 6 meters;

Ribbed belt conveyor, conveying medium conveying limit: 150kg, unit length load limit: 1kg/cm, the maximum length cannot exceed 12 meters;

Ribbed belt conveyor, conveying medium conveying limit: 150kg, unit length load limit: 1kg/cm, the maximum length cannot exceed 12 meters;

Accumulation roller chain conveyor, conveying medium conveying limit: 2200kg, unit length load limit: 2kg/cm, maximum length cannot exceed 25 meters

Accumulation type roller conveyor, conveying medium conveying limit: 4000kg, maximum length cannot exceed 8 meters

Pallet conveyor systems allow for the selection of the most appropriate conveying medium based on varying load requirements. To identify the optimal type, consider both the weight capacity and maximum size of the loads. This approach ensures a cost-effective solution that effectively balances performance with economy.

Functions of conveyors

Conveyors have many functions, mainly including the following:

1. Carrying items: pallet conveyors can carry, transport, and stack various items.

2. Improving production efficiency: pallet conveyors can effectively improve production efficiency. Because they can carry items quickly and accurately, and can carry multiple items at a time, saving manpower.

3. Saving labor costs: pallet conveyors can automatically carry and transport items, reducing manual operations and reducing labor costs.

4. Ensure safety: pallt conveyors can carry and handle hazardous environments and harmful substances to ensure the safety of employees.

5. Increase production capacity: In industrial production, pallet conveyors can shorten production cycles, increase production capacity. And reduce the labor intensity of workers.

Types of Pallet Conveyors and Precautions for Purchase

Depending on the different conveyed items, pallet conveyors also have different types, mainly belt conveyors, screw conveyors, transporteurs de chaîne, bucket conveyors, etc.. When purchasing a conveyor, it is necessary to consider production needs, item size, weight. And other aspects to select the appropriate type and specification of conveyor.

-300x300.png)