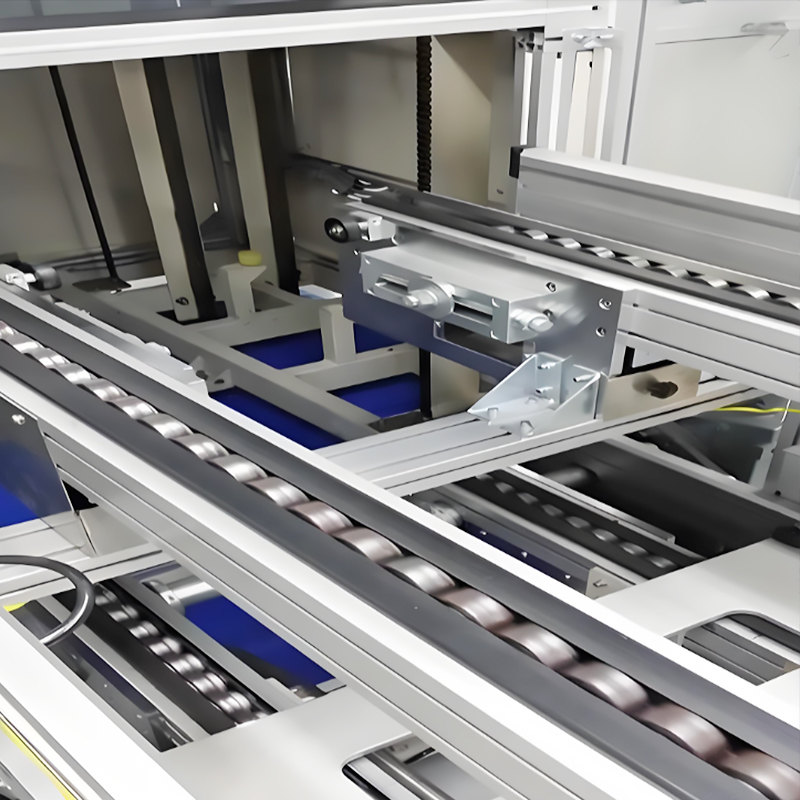

Pallet chain conveyors, a solution for efficient and reliable pallet handling in the realm of industrial automation. Designed to optimize material flow and streamline operations, our pallet chain conveyor system offers unmatched versatility and durability.

Description

Convoyeurs à chaîne de palettes en aluminium Toshine

Which Conveyor is Also Called Pallet Type Conveyor?

Pallet conveyor is a kind of conveying equipment that uses pallets as a carrier. It places goods on pallets through a series of conveyor belts, chaînes ou rouleaux, and transports them continuously or intermittently. People use pallet conveyors widely in warehouses, lignes de production, logistics centers and other occasions to achieve fast and stable transportation of goods. So pallet conveyors are including some belt conveyors, transporteurs de chaîne, roller conveyors that will work with pallets.

What Application You Use a Chain Conveyor for?

When considering the use of a chain conveyor, it is essential to understand its strengths and limitations. Chain conveyors are ideal for moving heavy products from one location to another with ease. Their simplicity and exceptional durability make them a reliable choice for various industries.

The flexibility of chain conveyors allows for both continuous and indexing modes. In indexing mode, the chain stops and starts using a sensor to move products to the end of the chain, providing precise positioning and control.

If the need arises to change the speed of the conveyor, a chain conveyor equipped with a variable frequency drive offers a simple solution. Adjusting the speed becomes effortless, améliorer l’efficacité opérationnelle.

Remember: Don’t Use Pallet Chain Conveyors When You Need

However, there are situations where a chain conveyor may not be the optimal choice. Par exemple, if you require accumulation of products for buffering purposes, chain conveyors are generally not designed to allow products to nest up against each other without pushing them off the chain or sideways. In such cases, roller conveyors or power and free overhead conveyors are more suitable options.

En plus, if your products have soft or uneven surfaces on the bottom, chain conveyors may not provide sufficient grip. Consider using a slat conveyor, which we can fitwith tooling to securely hold the product in place as the conveyor moves along. People can equip some chain conveyors with pins to hold skids or other part location devices.

It’s important to note that chain conveyors are not recommended as working surfaces for production operations. People primarily design them for transportation purposes. If you require a conveyor for production operations, consider using a slat conveyor or roller conveyor instead. However, if utilizing a chain conveyor as a working surface is necessary. That can ensure proper safety measures and guarding are in place to prevent injuries.

Chain conveyors are not suitable for moving products up or down inclines, as the products may slide easily on the chains. For transferring products from one chain conveyor line to another around curves, we suggest a 90-degree transfer mechanism.

Understanding the specific requirements and limitations of chain conveyors will guide you in making informed decisions about their utilization. Explore the full potential of our chain conveyor solutions. And let our experienced professionals assist you in optimizing your material handling processes. Contact us today to discuss your unique needs and find the perfect chain conveyor solution for your industrial automation requirements.

What Can We Help You?

At our company, we understand the importance of tailoring pallet conveyor units. And that will meet the unique task requirements of our clients. We take pride in offering a diverse range of pallet handling equipment, ensuring that we have the perfect solution for every need. Our selection includes chain conveyors, buffer conveyors, platines, transfer units, distributeurs de palettes, and pallet testers.

What sets us apart is our modular approach, which allows businesses to easily customize their pallet conveyor system. Our system consists of a range of standard components that can be combined and added as we need. Whether you require lifts, shuttle cars, lane connections, crossovers, roller lanes, or any other element, our modular solutions make it effortless to expand and adapt your conveyor system to meet evolving operational demands.

Experience the benefits of our tailored, diverse, and modular pallet conveyor solutions. Contact us today to discuss your specific requirements. And let our experienced professionals guide you towards the perfect pallet conveyor system for your industrial automation needs.