Timing belt conveyors feature a toothed belt that provides precise positioning and speed control. They are perfect for industries like automotive, électronique, and food processing.

Plus, they operate quietly, creating a better workspace. With reduced maintenance needs, you can save time and costs. You can also customize their size and configuration to fit your specific needs. Dans l'ensemble, our timing belt conveyors enhance your workflows and reliability.

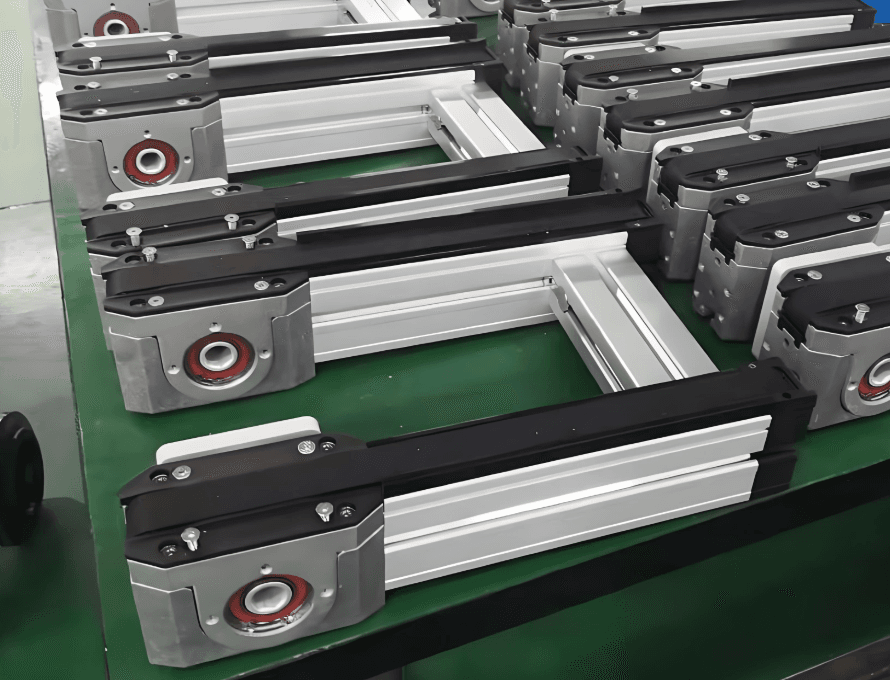

Description

Toshine Modular Timing Belt Conveyors

Understanding Timing Belt Conveyors: Boost Efficiency in Material Handling

Timing belt conveyors are essential in automation and material handling. En plus, these innovative systems efficiently transport goods along production lines. By using a toothed belt that engages with pulleys, they offer precise movement. In this article, we will learn the features, benefits, candidatures, and maintenance tips for timing belt conveyors.

What is a Timing Belt Conveyor?

A timing belt conveyor is a mechanical system designed for moving products from one point to another. Traditional conveyors rely on friction, but timing belt conveyors use a belt with interlocking teeth. Ainsi, this belt meshes with drive pulleys, allowing for exact control over speed and positioning. So this design makes timing belt conveyors ideal for tasks where accuracy is crucial.

Key Features

Precision and Accuracy: One of the standout features of timing belt conveyors is their precision. They deliver consistent and accurate movement. This precision is especially beneficial in assembly lines, where components must align perfectly. Inaccuracies can lead to costly errors, making this feature invaluable.

Versatilité: Timing belt conveyors are highly versatile. Because they can handle various products, from small components to larger items. Industries such as automotive, électronique, food processing, and packaging greatly enjoy this versatility. Par exemple, in food processing, these conveyors efficiently move items through processing and packaging stages.

Low Noise Operation: Another advantage is their quiet operation. Timing belt conveyors produce less noise compared to traditional belt systems. This feature contributes to a more pleasant work environment, reducing noise pollution. In workplaces where communication is key, such as assembly lines, this can significantly enhance productivity.

Reduced Maintenance: Timing belt conveyors generally need less maintenance than traditional systems. Their robust design minimizes wear and tear. This characteristic leads to lower costs and less downtime due to repairs. Fewer maintenance requirements mean you can focus more on production and less on equipment issues.

Efficacité énergétique: These conveyors are designed to be energy-efficient. Their precise motion reduces energy consumption. Today, this feature not only lowers operational costs but also contributes to sustainability efforts. Businesses looking to reduce their carbon footprint find timing belt conveyors appealing.

Benefits of Using Timing Belt Conveyors

Increased Productivity: The precision offered by timing belt conveyors can lead to significant improvements in production efficiency. Accurate positioning and consistent speed optimize processes. And they allow for more items to be handled in less time. This efficiency can directly boost a company’s bottom line.

Enhanced Safety: Timing belt conveyors also enhance workplace safety. Their design minimizes the risk of slippage or misalignment. This feature creates a safer environment for employees. So that will reduce the likelihood of accidents and injuries. A safer workplace can lead to lower insurance costs and improved employee morale.

Customizability: Timing belt conveyors can be customized to meet specific requirements. You can adjust the size, longueur, and configuration of the conveyor system. This flexibility allows businesses to create solutions. And that will fit their operational needs perfectly. Customization can lead to more efficient workflows and better use of space.

Improved Product Handling: The ability to control speed and positioning helps reduce product damage during conveying. This feature is crucial in industries where fragile or sensitive items are handled. By minimizing damage, businesses can reduce waste and improve profitability.

Integration with Automation Systems: Timing belt conveyors can easily integrate with other automation systems. This capability allows for seamless workflows in complex manufacturing setups. By connecting to robotics or other machinery, these conveyors enhance operational efficiency.

Applications

Timing belt conveyors serve a wide range of industries, including:

Automotive Industry: They assist in assembling vehicles and transporting components with high precision. This efficiency ensures that production lines operate smoothly and effectively.

Food and Beverage Industry: These conveyors are ideal for moving products through processing lines, packaging, and labeling. So they help maintain hygiene standards, a crucial aspect in food handling.

Fabrication d'électronique: Timing belt conveyors ensure the accurate placement of electronic components during assembly. Ainsi, precision is vital in this industry to prevent defects.

Médicaments: In the pharmaceutical sector, timing belt conveyors handle delicate materials in controlled environments. They help maintain the integrity of products, ensuring compliance with industry standards.

Maintenance Tips

To ensure your timing belt conveyor operates efficiently and lasts long, follow these maintenance tips:

Regular Inspections: Conduct routine checks to identify any wear on the belt or pulleys. Early detection can prevent costly repairs and downtime. Regular inspections can save time and resources in the long run.

Proper Tensioning: Ensure the timing belt is correctly tensioned. An improperly tensioned belt can lead to slippage or premature wear. Correct tensioning helps maintain optimal performance.

Propreté: Keep the conveyor system clean and free of debris. Dirt and grime can affect the performance of the timing belt. Regular cleaning ensures smooth operation and prolongs the lifespan of the conveyor.

Lubrification: Some components may need periodic lubrication. Proper lubrication ensures smooth operation and reduces friction. So this maintenance step is crucial for long-term reliability.

Professional Servicing: Schedule regular maintenance with professionals who specialize in conveyor systems. Because they can provide expert advice and ensure that your system operates at peak performance.

Conclusion

En un mot, timing belt conveyors are essential tools in modern manufacturing and material handling. Their unique design is combined with benefits like precision, versatility, and low maintenance. So that will make them a preferred choice in various industries.

By learning the features, benefits, and applications of timing belt conveyors, businesses can optimize their operations and achieve higher efficiency. Implementing a timing belt conveyor system is not just a step toward automation. It is a significant investment in the future of your production processes.