Pallet conveyors are essential components in industrial automation, designed to efficiently transport palletized goods within manufacturing facilities, warehouses, et centres de distribution. These conveyors are engineered with precision to handle a wide range of pallet sizes and weights, optimizing material handling processes and streamlining workflow operations.

With advanced features such as adjustable speeds, versatile configurations, and durable construction, pallet conveyors play a vital role in enhancing productivity and ensuring seamless logistics in various industries.

Description

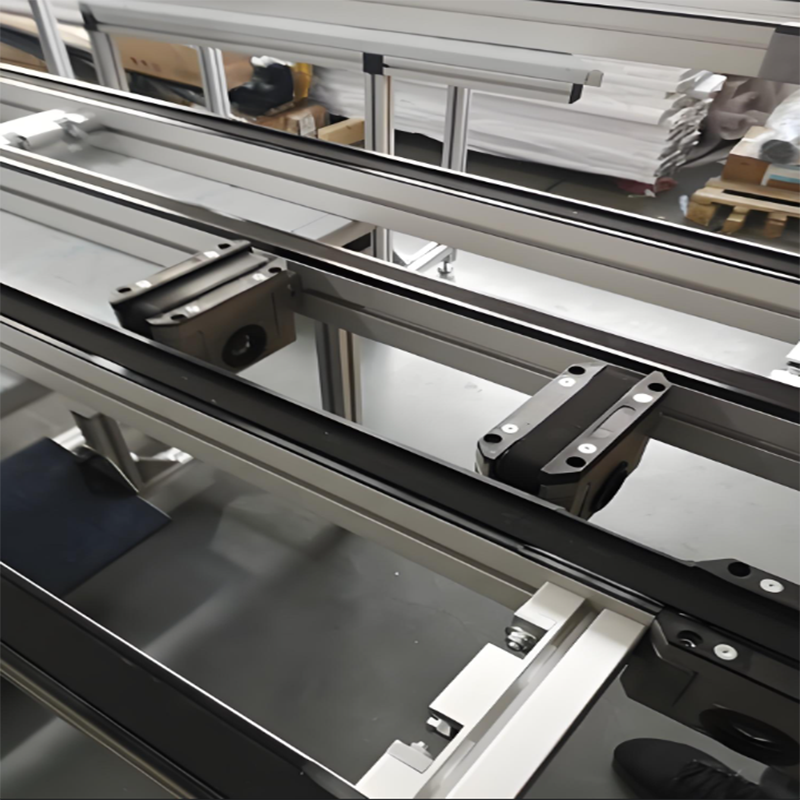

Système de convoyeurs à bande de palettes Toshine

Pallet conveyors mainly includes the following types:

Transporteur à chaîne: Uses chain as transmission device, we can use it for long-distance transportation, suitable for heavy materials or pallet transportation.

Convoyeur à rouleaux: Uses rollers to support and convey pallets, usually used for medium and short-distance material transportation, suitable for assembly line operations.

Slat Conveyor: Uses flat chain or chain plate as transmission device, suitable for heavy and irregular-shaped pallet materials.

Vertical Lift Conveyor: Used for vertical transportation, transporting pallets from one layer to another to save space.

Pallet Transfer Machine: Usually driven by an electric motor or pneumatic device, using mechanical structures such as slide rails, transmission chains or conveyor belts to automatically move pallets from one location to another.

Pallet Destacker: Mainly used to separate stacked pallets. The separated pallets are usually transferred to another location. That can be a conveyor line loaded with goods or another stacking area.

Selection of Pallets

Material Selection: The material of the pallet plays a crucial role in its performance and durability. Common materials include wood, plastic, and metal. Wooden pallets are lightweight and easy to process, but they can deform easily when exposed to moisture.

Plastic pallets are also lightweight and easy to clean, but they have a lower load-bearing capacity. On the other hand, metal pallets offer higher load-bearing capacity and durability, although they are heavier. Donc, the choice of material should be based on the specific environment and needs.

Size and Load-Bearing Capacity: The size of the pallet should match the actual use scenario and requirements. For instance, larger pallets are needed for placing large equipment or goods, while smaller pallets are suitable for small items or precision instruments. En plus, it’s important to ensure that the pallet’s load-bearing capacity meets your needs. En général, higher load-bearing capacity correlates with higher quality and price.

Stiffness and Structure: The stiffness of the pallet is vital for maintaining stability and safety during logistics operations. Key indicators to consider include static load (pressure data when stacked on the ground), dynamic load (simulating load-bearing capacity during forklift operations), and shelf load (simulating deformation detection when supported by shelf beams).

Special-purpose pallets may require additional inspections. Par exemple, in a stereoscopic warehouse, you need to consider the size standardization and load-bearing capacity of the pallet.

Other Selections of Pallet Conveyors

Fonctionnalité: The functionality of the pallet encompasses shelf loadability, stackability, and nestability. Shelf loadability considers the different requirements of various shelf types for pallet loads. Stackability is important for scenarios requiring multi-layer stacking, while nestability is suitable for saving storage space. En plus, anti-slip performance is crucial for ensuring operational safety.

Compatibility with Peripheral Equipment: The design of the pallet should be compatible with peripheral equipment such as conveyors and forklifts. This includes the pallet’s fork entry method and anti-slip design, which are essential for improving logistics efficiency and operational safety.

Standardization: In the circulation field or when pallets need to be rented, using standard-sized pallets is the best choice. Standardized pallets facilitate circulation and exchange, while also reducing costs.

In summary, selecting the right pallets for pallet conveyors involves a comprehensive consideration of factors. Such as material, size, load-bearing capacity, structure, functionality, and compatibility with peripheral equipment. This ensures the performance and safety of the pallets while optimizing logistics efficiency and cost.

Are You Ready to Contact Us?

Pallet conveyors are the go-to solution for smoothly moving palletized goods in factories and warehouses. As an expert in industrial automation, I urge you to consider upgrading your material handling with a pallet conveyor.

Let’s work together to find the perfect pallet conveyor for your needs and boost your workflow efficiency. With my knowledge in conveyor systems, we’ll create a tailored solution that takes your operations to the next level.

Don’t miss out on the chance to make your work easier, increase productivity, and improve your logistics with a pallet conveyor. Reach out today to start improving how you handle materials and set your business up for success in industrial manufacturing.

Get in touch now to start your journey towards smoother operations and better material handling with a pallet conveyor.