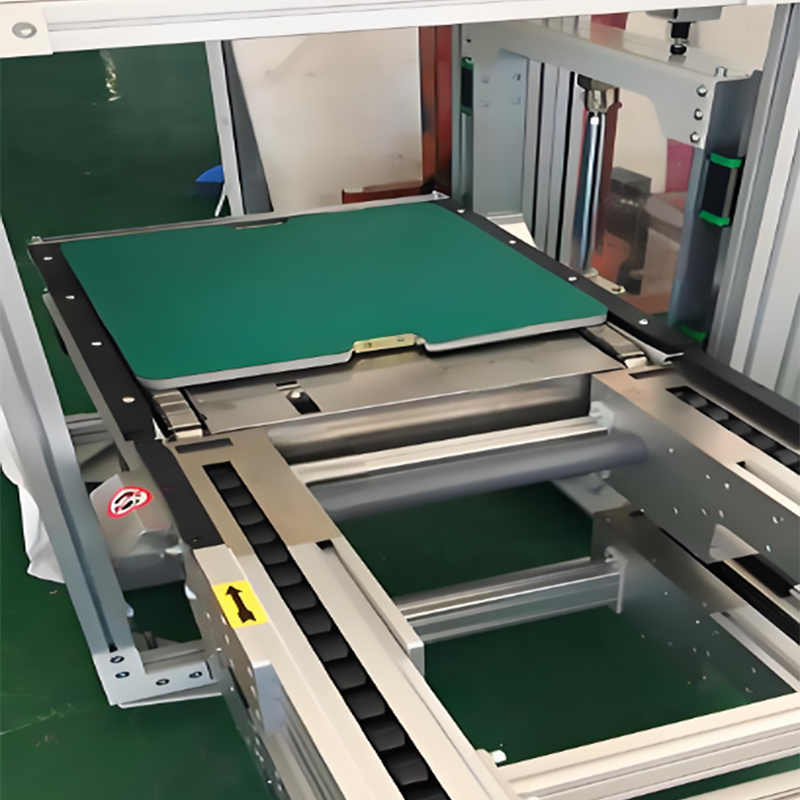

With its ability to adapt to different pallet configurations and integrate seamlessly into existing production lines, the pallet conveyors play a crucial role in optimizing material flow and minimizing manual handling. From loading and unloading to transferring pallets between workstations, this conveyor system simplifies complex logistics processes and improves operational efficiency.

Description

Toshine Pallet Conveyors Automation Systems Manufacturer

What are the features and applications of pallet conveyors?

In conveyor lines and related functional components, in addition to the more common belt conveyors, flexible chain conveyor lines, convoyeurs à rouleaux, etc., the utilization rate of pallet conveyors is also very high. Then, regarding the specific product features and application areas of pallet conveyors, this article will introduce this knowledge in detail.

1. Advantages of pallet conveyors

1) As a series of conveyor products, it is necessary to first measure its advantages and disadvantages from the perspective of conveying capacity. Compared with similar products, the conveying capacity of pallet conveyors belongs to a relatively strong range. Parmi eux, the more representative ones like toothed belt pallet conveyors and sheet-based belt pallet conveyors have strong conveying capacities.

2) The traction strength of pallet conveyors is relatively high, so it is completely suitable for work scenarios that require long-distance transportation. In the process of long-distance transportation, pallet conveyors can guarantee the stability and reliability of the entire process to the greatest extent, which is impossible for many types of conveyors.

3) We can arrange the conveying line of pallet conveyors flexibly. Because pallet conveyors can meet the conveying needs of smaller inclination angles and larger bending radii. In contrast, belt conveyors generally cannot meet this type of conveying requirements. And their conveying function is less flexible than that of pallet conveyors.

4) Pallet conveyors can support a wide range of materials for conveying. Under normal circumstances, as long as they are not dangerous goods or highly viscous objects, pallet conveyors can convey conventional solids. De plus, during the entire material conveying process, sorting, assemblée, cooling, drying and other operations can be performed at any time.

2. Disadvantages of Convoyeurs de palettes

1) The overall frame and various internal parts of the pallet conveyor are made of metal as raw materials. So the overall weight and volume of the pallet conveyor are relatively large. Donc, it will appear bulky and inconvenient to install quickly when the space is relatively small.

2) The structure of the pallet conveyor is relatively complex, and there are many types of internal parts. Based on the various problems in the manufacturing process of the pallet conveyor, the price of the pallet conveyor is also relatively expensive.

3) In the process of material conveying, the conveying bottom plate and traction chain of the pallet conveyor will wear faster. And due to the limitations of its own structure, the steps of adding lubricating oil to the pallet conveyor are more troublesome. When a conveyor fails, it is not easy to repair it.

4) The pallet conveyor also requires a large power when it is unloaded. So there is still room for improvement in energy utilization. The problem of high conveying noise is also something that users must consider before choosing a pallet conveyor.

Conveyor Mode

The conveyor mode refers to an automated pallet conveying system made up of various types of conveyors. These pallet conveyors can be roller type, chain type, plate type, or even lifting platforms. In automated warehouse systems, to meet the capacity requirements for pallet goods, roller conveyors with high efficiency are typically chosen. And they are often combined with chain conveyors to create a comprehensive pallet conveying system.

Depending on the needs of the operation, people can use a single conveyor to form a specific function within the system. Or we can combine multiple types of conveyors to create a more versatile pallet conveying system.

Advantages of Conveyor Mode

1. Continuous Conveying: This method allows for uninterrupted transport of materials. Loading and unloading can occur without stopping the conveyor, eliminating the need for empty returns and reducing interruptions.

2. High Capacity: The system can handle large volumes of materials continuously, making it highly efficient.

3. High Speed: Since the system doesn’t require frequent starts and stops, it can operate at higher speeds.

Dans l'ensemble, the conveyor mode offers a reliable and efficient solution for automated material handling in various industrial settings.

We’re genuinely excited to help you enhance your material handling process with our Pallet Chain Conveyor. Its robust construction, high load capacity, and customizable design make it an excellent choice for streamlining operations and boosting productivity. We believe this conveyor can make a real difference for your business. Contact us today to learn more, and let’s work together to create a more efficient and safe workflow for you.