Belt conveyors are favored in many industries due to their efficiency and safety. They are capable of moving goods in a straight line or through changes in elevation or direction. This adaptability makes the belt conveyor system ideal for complex paths and allows it to integrate smoothly into existing production or distribution lines.

Description

Aluminum Belt Conveyor Supplier

Rubber belt conveyors, another term for belt conveyors, are integral to a multitude of sectors including home appliances, electronics, electrical machinery, tobacco, injection molding, post, telecommunications, printing, and food for tasks like assembly, testing, debugging, packaging, and object transport.

Depending on the operational requirements, you can opt for various conveying modes, like the standard continuous run, cycle-based operation, or speed-variable functioning. The conveyor structure is adaptable to local conditions and can take various forms, such as straight lines, curves, or slopes. Conveyors range from robust, heavy-duty mining conveyors to lighter versions for the electronic, plastic, food, light industry, chemical, and pharmaceutical sectors based on their load capacity.

With high-capacity, lengthy distance transport capabilities, belt conveyors are simple to maintain and easily integrated with programmed controls and automated operations. They can move goods up to 100KG or granular items, functioning continuously or intermittently at high speeds, smoothly and quietly, and can handle both inclines and declines.

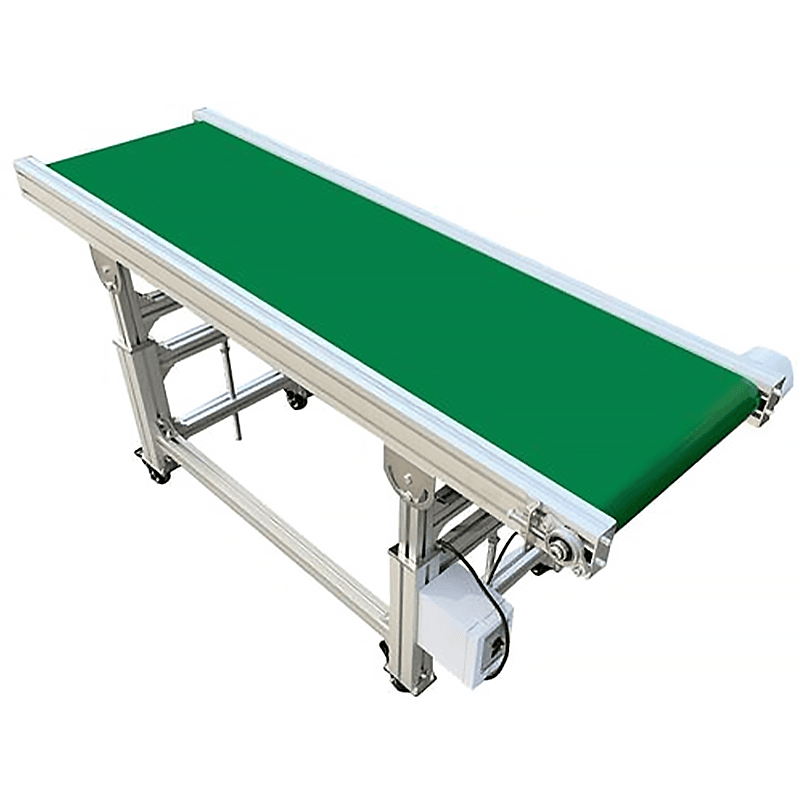

As friction-powered machines, belt conveyors offer seamless transportation of materials. Comprising a frame, conveyor belt, rollers, drums, tensioning mechanisms, and transmission devices, they facilitate a material transfer process from the initial feed to the final drop-off within a predefined line. Meanwhile, they transport packaged items and bulk materials alike. Beyond simple transportation, they sync with various industrial production processes to craft rhythmic operational transport lines.

Common Conveyor Types

Modern conveyor systems typically use motor-driven mechanisms, propelling belts or rollers to move forward and transport items like crates or pallets.

Belt Conveyors

Belt conveyors are prevalent in storage and logistics centers, known for their straightforward and robust structures, capable of continuous transport with flexible, site-specific layouts. Primarily used for lighter loads such as boxes or parcels, they lack accumulation or caching capabilities. When active, they move all materials situated atop them in unison.

Seoltóir sorcóir

Roller conveyors utilize a series of fixed brackets with rollers to move finished goods. Configurable with straight or curved segments as required, they can function independently or with other assembly line machines or conveyors. They are simple to install or remove, require minimal upkeep, and offer versatile line configuration choices. These conveyors smoothly transport items with flat bottoms, like slabs, rods, tubes, profiles, pallets, or containers, across horizontal or slightly inclined paths. Suitable for flat-bottomed items, they may require pallets for irregularly shaped or soft goods, offering high capacity, luas, and light operations. The standout feature of roller conveyors is their compatibility with the production process, boasting diverse functionalities.

Seoltóir Slabhra

Chain conveyors parallel the operational principle of belt conveyors. But differentiate by using a continually moving chain, garnished with attached plates for goods conveyance. While the belt version relies on friction for movement, the chain conveyor operates via coupling traction. Suitable for transporting heavier loads like pallets, chain conveyors necessitate that the pallet’s underside align with the direction of the moving chain. The versatile structure of the conveyor chain allows its application across multiple environments and requirements.

Aluminum Belt Conveyors: Paragons of Excellence and Productivity

1. Product Attributes: Noteworthy benefits are abundant with aluminum belt conveyors. Their casings, crafted from a lightweight aluminum alloy, bestow superior durability and anti-corrosive properties. Therefore, this feature prolongs equipment lifespan and slashes maintenance expenses.

Additionally, their all-aluminum build renders the conveyors notably portable and straightforward to assemble. The belts employed are recognized for robustness, resistance to wear, and ease of cleaning. So that will make them ideal across diverse operational conditions.

2. Utilization Contexts: Aluminum belt conveyors have become pillars across various sectors. Employed to move both packaging and final products within food processing, pharmaceuticals, electronic goods. Besides, they also shine in roles within warehouse coordination, logistics transit, and production line mechanization.

3. Comparative Advantages: When measured against counterparts like steel or stainless steel belt conveyors, the aluminum variety stands out distinctly. Besides, aluminum delivers a resilient structure capable of resisting wear, facilitating cleaning, and shouldering heavier operational demands for an extended lifespan. The lighter makeup of aluminum conveyors enhances maneuverability and installation ease, fulfilling a broad spectrum of environmental conditions with finesse.

In Conclusion

In a word, belt conveyors are a staple in material transport within contemporary industry. And they shift an array of materials with efficacy and ease, underpinning seamless production processes. This discussion delves into the benefits, usage contexts, and customer value of all-aluminum belt conveyors.

The industry-wide migration toward all-aluminum belt conveyors is spurred by their stellar performance, versatility in applications. And the substantial value they contribute to clienteles. Companies that opt for these conveyors not only boost productivity but also cut down on operational costs. For those seeking an efficient, eco-friendly transport solution, the all-aluminum belt conveyor represents a top-tier choice worthy of consideration.

Advantages of Aluminum Profile for Belt Conveyors

1. Wide Range of Options: You’ll find an extensive array of specifications and types to choose from. So whatever your needs, there’s an industrial aluminum profile that’s perfect for building the backbone of your conveyor belt system.

2. Sleek Yet Strong: With its double anodized finish, the conveyor belt’s aluminum profile not only looks sharp but also boasts impressive strength for carrying heavy loads.

3. Easy to Put Together: The beauty of modular industrial aluminum profiles is their ease of assembly. They snap together without welding, making setup and relocation a breeze.

4. Built to Last: The aluminum profile is treated with a protective film to fend off wear and tear, corrosion, and oxidation, ensuring it stays in top condition even after heavy use.

5. Hassle-Free Upkeep: Maintenance is a cinch thanks to the oxidized surface that forms a self-protecting layer. Plus, the standard modular parts are not only readily available but also affordable, keeping long-term care costs down.

6. Tailor-Made Versatility: Cut and customize the aluminum profile of your conveyor belt to fit your exact needs. And if you need something truly unique, special non-standard profiles can be created just for you.