Our Bespoke Industrial Safety Guards are manufactured from select materials chosen for their strength, durability, and compliance with industry standards. From robust aluminum profiles that offer a lightweight yet sturdy frame, to high-impact polycarbonate panels that allow for clear visibility and superior protection, every element is chosen with your industrial requirements in mind.

Description

Bespoke Industrial Safety Guards Maufacturer

Industrial equipment protective guards create a defined safety zone around machinery, marking off secure areas and preventing direct human or object contact with the equipment, while acting as a visual safety alert. These covers regularly function in tandem with alarm systems and cut-off mechanisms.

So the function of industrial aluminum profile equipment protective covers includes:

Dust Isolation: The covers create a barrier between the equipment and the surrounding environment, effectively preventing dust ingress, which substantially prolongs equipment life.

Operator Safety: By creating a physical barrier between machinery and operators, protective covers markedly diminish the possibility of accidents during equipment operation.

Noise Attenuation: The operation of machinery can be noisy; when encapsulated within aluminum profile protective covers. So the noise levels in the workplace are significantly reduced, contributing to a more focused and emotionally stable workforce.

Aesthetic Enhancement: The use of industrial aluminum profiles in the construction of equipment covers adds an aesthetically pleasing and sophisticated look to the workshop, promoting an organized and professional environment.

Varieties of Aluminum Profile Frames Include:

1. Aluminum Profile Shelving:

These frames by using aluminum profiles to form a structure that facilitates the placement of equipment or items for use. An example is depicted below – a custom aluminum profile shelf for our clients.

2. Workbenches:

Besides, we offer customization for various types of workbenches such as those used in workshops, assembly lines, laboratories, and for fitters. Below is an illustration of a bespoke laboratory workbench we crafted for a research institution.

3. Machine and Equipment Guards:

Also known as equipment dust covers, aluminum profile chassis, or cabinets, these guards are tailored to protect machinery. Featured below is one such equipment dust cover we’ve customized.

4. Safety Barriers:

In light of the increased use of large machinery, safety barriers, including those for robots and workshops, have seen a rise in demand. Below is an image of a robot safety barrier made from aluminum profiles, crafted to specification.

5. Everyday Uses:

Everyday applications might include structures for whiteboards, aquarium stands, aluminum profile doors, and beds. See below for an aluminum profile-based custom fish tank stand.

Selecting the Right Baffle for an Aluminum Profile Guards:

The aluminum profile guard serves multiple purposes: it operates as a safety warning, ensures uninterrupted machinery functioning, safeguards worker safety, and enhances the look of mechanical equipment. In everyday applications, a guard is more than just an aluminum profile frame—it requires the installation of specific baffles to be fully operational.

1. Standard Guard Baffles:

Typically made up of mesh grids, these baffles facilitate efficient heat dissipation. Mesh grid baffles are affordable and straightforward to install, often secured with pressure strips, resulting in a durable and attractive solution. Yellow-sprayed mesh grids are popular choices for equipment such as robots, as the color functions as a visual warning, keeping workers clear of the robot’s operational space and minimizing accidental injuries.

2. Upgraded Baffle Options:

For specific guarding needs, one might opt for baffles made from acrylic or aluminum composite panels. Acrylic panels come in various shades like clear, bronze, and brown, each serving a different guard function. For instance, clear acrylic allows for monitoring machinery in operation, while tinted options offer shade and privacy. Using an aluminum composite panel baffle turns the guard into a dust-proof, noise-insulating enclosure.

3. Aluminum Alloy Baffles:

For even higher durability and aesthetics, baffles crafted from aluminum alloy plates are an option. With their superior hardness and sleek look, these plates provide enhanced impact resistance compared to mesh or acrylic alternatives. They come at a premium, but are a worthy investment for large-scale equipment operations that demand stringent environmental controls.

Cásanna

As long as it can meet the needs of use, all are good cover frames. Below, the editor will explain to you in detail the specific application cases of aluminum profile covers.

Robot aluminum profile protective enclosures and guards

Modern factories are inseparable from the use of robots, which can achieve long-term and accurate processing. In order to have a safe operating environment, it is necessary to install a protective cover around the robot to reduce the impact of the external environment on the robot’s operation.

The robot’s aluminum profile protective cover in the picture below is with 4040 aluminum profiles. Meanwhile we install black flat sealing groove strips in the profile grooves, which are beautiful and dust-proof.

Equipment enclosures and guards

The most commonly used aluminum profile covers are mechanical equipment covers. Because we usethem often on equipment of various structures to wrap the equipment and play a protective role. Such as chassis covers, assembly line covers, cabinet covers, etc., all belong to the scope of equipment covers.

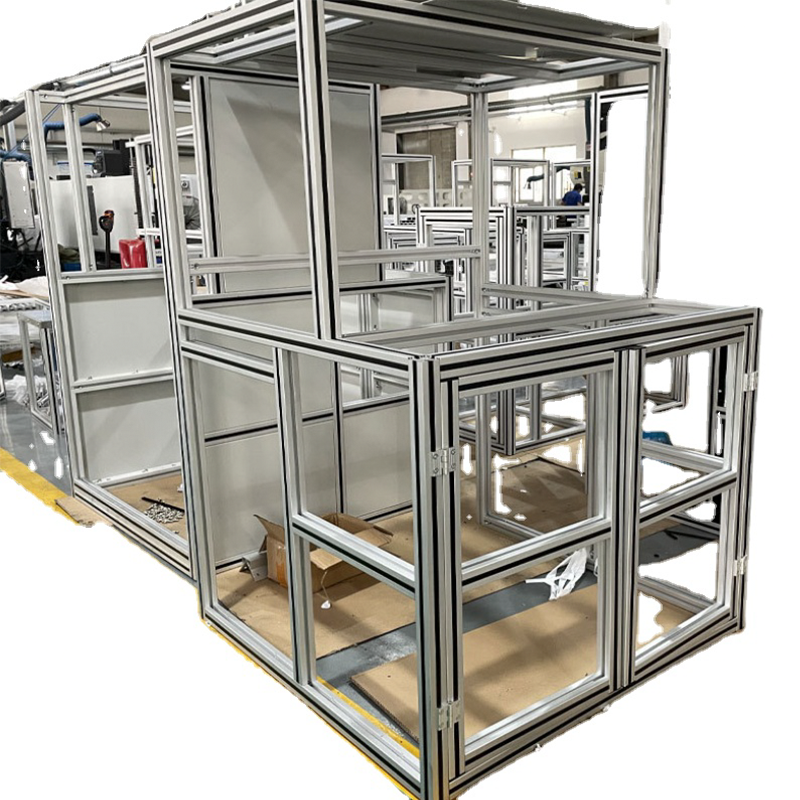

Workshop partition enclosures guards

This kind of outer cover is equivalent to a house. It is a partition protective cover with aluminum profiles and plates at a specified location in the workshop. So we can use it to place various mechanical equipment or operating tools or materials.

The picture shows such a cover frame. Because it occupies a relatively large area, it is generally with profiles of 8080 and above specifications, which has better load-bearing capacity.

In Conclusion

The combination of profiles of different specifications, accessories with different connection methods. And plates of different materials will build aluminum profile covers with different styles and functions. In many customers’ offices, you will find various customized cover frames according to the shape of the mechanical equipment.