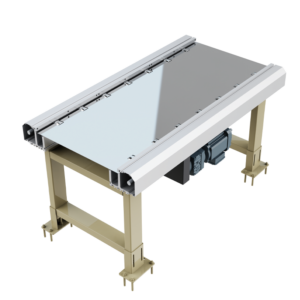

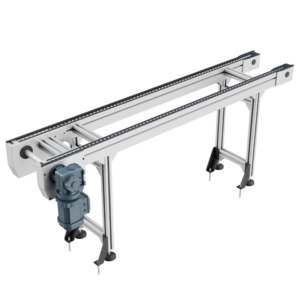

Chain conveyors consist of a series of chain links that form a continuous loop, which is powered to move materials along the conveyor path. Known for its durability and strength, the chain conveyor can handle a wide array of materials ranging from bulky items to smaller components.

Description

Chain Conveyors Supplier for Heavy Loads

Here are composition and principle of chain conveyors:

1. The core element, the chain, propels materials along the chain conveyors from start to finish. Crafted from metals like cast iron, steel, or stainless steel, the chain’s design varies, including straight, curved, and prismatic types. Regular inspections and maintenance are critical to the smooth operation of the chain conveyors.

2. Enabling the transfer of power within the chain conveyors is the transmission device. This vital component often encompasses motors, gear reducers, and hydraulic units. Motors primarily convert electric into mechanical energy, moving the chain to transport materials, while gear reducers regulate conveyor speed. And hydraulic systems offer precise control over the conveyor’s operations.

3. Integral to the chain conveyors is the bracket, which supports elements like the sprocket and chain. Crafted from structurally solid materials, the bracket is anchored securely to ensure the conveyor’s safe and reliable function.

4. Enhancing material flow, the vibrator within the chain conveyors is essential for improving efficiency. By generating vibrational forces, it propels materials with reduced friction, available in motorized or pneumatic designs.

Operating Principle:

Initiating the process, the power from the motor and transmission is relayed to the chain, starting its journey, while the vibrator assists by nudging materials forward through vibration. As goods traverse from one end to the other, they are discharged seamlessly, maintaining the chain conveyors’s effectiveness.

To summarize, chain conveyors comprises chains, a transmission device, brackets, a vibrator, and other elements, working harmoniously to offer a straightforward yet effective conveying solution. In a word, adjustable and adaptable, chain conveyors meet varied industry demands and accommodate a vast range of material handling needs.

Advantages

- Exceptional Load Handling: Chain conveyors use chains for transporting materials and can handle heavy loads better than many other systems. Their strong design allows them to carry substantial weight without bending or breaking.

- Rapid Conveying: Chain conveyors are highly efficient at moving large, long-distance items, saving time and effort compared to traditional methods. And we can easily integrate them into logistics operations for quick loading and unloading. Besides, we can adjust their speed to suit different material weights and logistical needs, increasing efficiency.

- Versatile Applications: Chain conveyors are suitable for a wide range of industries, from handling heavy raw materials to lighter applications like food processing. Besides, they can transport various types of items, including long, granular, solid, and even liquid materials.

- Improved Durability: Built to last, chain conveyors use sturdy external materials. So they can be enclosed to adapt to different environments, providing resistance to various climates. Advanced manufacturing processes and stringent design standards ensure a long service life while minimizing maintenance costs.

- Easy Structure & Maintenance: With its simple design and few components, the chain conveyors are easy to maintain. Troubleshooting and upkeep are uncomplicated, reducing downtime and costs. Customized maintenance plans can be created to ensure continuous high-performance operation.

In summary, people value chain conveyors for their high capacity, efficiency, versatility, durability, and low maintenance. People widely use them in many industries and expect to see further growth in logistics applications as automation advances.

Scope of Application of Chain Conveyors

- Logistics field: we often use chain conveyors widely in cargo transportation and storage in warehousing logistics. Such as express delivery, logistics companies, srl.

- Manufacturing industry: In the manufacturing industry, we often use chain conveyors for material transportation and transfer on robot processing and assembly production lines. Such as automobile manufacturing, home appliance manufacturing, srl.

- Food industry: Due to the fast conveying speed and stable transportation of chain conveyors, we also use them widely in food packaging and transportation on production lines in the food industry.

- Coal mines, quarries, etc.: People often use chain conveyors in coal mines, quarries and other industries for material stacking and processing. So this can help improve production efficiency.

Application and Advantages of Suspension Chain Conveyors Line

1. Application industry:

- Coating industry: In the coating production line, the suspension chain conveyors line can smoothly convey the workpiece to ensure uniform and collision-free coating.

- Furniture manufacturing: In the process of furniture assembly and spraying, the suspension chain conveyors line can achieve efficient circulation.

- Metallurgy and casting: In high temperature environment, the suspension chain conveyors line can reliably transport heavy castings and metal materials.

- Rubber and plastic: In the process of molding, cooling and packaging of rubber and plastic products, the suspension chain conveyors line provides continuous transportation support.

2. Advantages:

- High space utilization: The suspension design makes full use of the vertical space and reduces the ground occupation.

- Good flexibility: We can adjust the conveying path and speed easily to adapt to different production layouts.

- Energy saving and environmental protection: Compared with other conveying methods, the suspension chain conveyor line generates less noise. And also generate energy consumption during operation.

- Strong safety: Ensure the safety of operators through reasonable design and protective measures.

Chain conveyors are a device that employs a chain as both the pulling mechanism and the load bearer for material transportation. Boasting a straightforward design, effortless operation, and hassle-free upkeep and cleaning, it’s a popular choice across various sectors. Industries ranging from mining to construction and chemicals frequently utilize chain conveyors due to their ability to facilitate the unbroken flow of materials, significantly enhancing material handling efficiency.