A belt conveyor is a simple way to move products and materials. It uses a strong belt that runs in a loop. So this system transports items smoothly.

Belt conveyors are common in many industries. Because they reduce manual work and boost productivity. You can customize them to fit your needs. You can adjust the speed or change the angle. They are ideal for assembly lines, packaging, and distribution. Overall, belt conveyor systems make logistics easier and improve workflow.

Description

China High Quality PVC Iompar Crios Series

What is a Belt Conveyor?

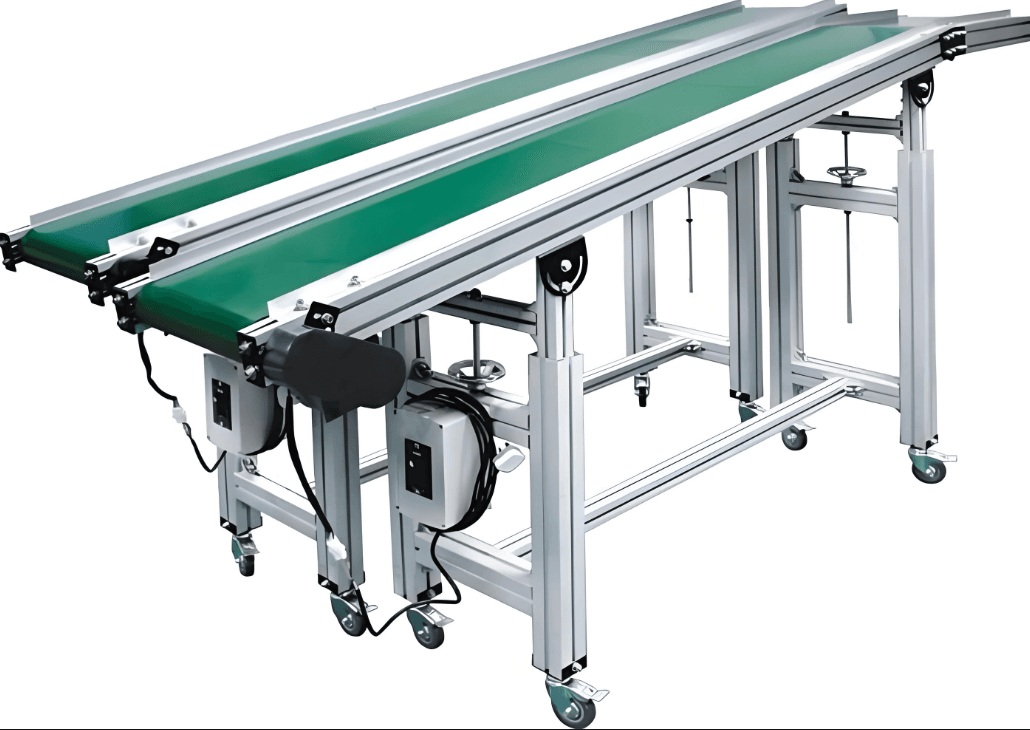

Structure: It consists of a transmission part and a conveying part. The overall frame is built with aluminum alloy, and the synchronous belt is driven by the motor for transmission. The power activates the active roller, propelling the belt into a continuous circular motion.

Basic function: The belt conveyor is a rhythmic and long-distance transmission of materials and pallets.

Features: It has strong conveying capacity, long conveying distance, simple structure and easy maintenance. Therefore, it can easily implement programmed control and automated operation.

Flat Belt Conveyor Series

Product Features

1. Compact: Through the optimization of the integrated profile structure, people can use it in a smaller space compared to conventional conveyors

2. Convenient maintenance: The structure simplifies the belt replacement steps and improves its maintenance convenience

3. More optimized price: Aiant has a greater cost advantage through its self-developed special structure

Use scenario

Low-load conveyors are suitable for occasions with small material conveying volume, short conveying distance, and low conveying height. Such as conveying light materials, short-distance conveying on loading and unloading lines, and material feeding on production lines.

Notes

1. Select the material characteristics: The selection of low-load conveyors needs to consider the material properties, such as particle size, fluidity, etc.. So that will ensure the stability and effectiveness of the conveyor.

2. Keep the conveyor clean: For low-load conveyors, it is necessary to clean the body, transmission system and other parts of the conveyor in time. So that will maintain performance and extend service life.

3. Regular inspection and maintenance: Low-load conveyors should be inspected and maintained regularly. Besides, wearing parts should be inspected and replaced to ensure the normal operation of the conveyor.

Synchronous Belt Seoltóir

Product Features

Heavy-duty synchronous belt double-row conveyors, people use them mostly for precise positioning and transmission of products.

The precise engagement of the synchronous belt and the synchronous wheel improves the transmission accuracy, so that the rotation angle of the motor is intuitively and accurately fed back to the synchronous belt, controlling the precise movement of the synchronous belt.

The drive mode of the synchronous belt has added stepper and servo drive motors. Besides, people can combine that with sensors and PLC for programmed movement.

Usage Scenarios

1. High load and high speed: Double-row synchronous belt conveyor can cope with large load and high conveying speed requirements. So it is suitable for occasions that require large-volume material transportation.

2. Long-distance transportation: Double-row synchronous belt conveyor has high stability. Besides, it can maintain stable material transportation over a long conveying distance.

3. Automated production line: Double-row synchronous belt conveyor can be seamlessly connected with the automated production line. So that will achieve automatic material transportation, sorting and processing.

Precautions

1. Regular inspection and maintenance: Regularly check the transmission parts, pulleys, belts, srl. of the double-row synchronous belt conveyor. Because that will ensure its normal operating state, clean up debris and replace worn parts in time.

2. Keep the conveyor belt clean: Ensure that the surface of the conveyor belt is clean. Because that will avoid the adhesion of impurities and oil stains to avoid affecting the operating effect and transmission quality.

3. Reasonable installation and adjustment: Correctly install the double-row synchronous belt conveyor. And adjust and calibrate it according to actual needs. So that will ensure the smoothness and accuracy of the conveying line.

Flat belt conveyor series

Product Features

High output type, the transmission surface is made of customized aluminum profiles. Besides, it is combined with a stainless steel pallet combination. Also it is suitable for high-load transportation.

In a word, the driven end knife edge design is suitable for relay transmission to avoid blockage in the material flow.

Use Scenarios

1. Production line material transportation: People often use knife-edge conveyors on production lines to transport materials, parts or finished products to achieve automation of the production process.

2. Packaging industry: In the packaging field, people can use knife-edge conveyors to transport packaged products from one workstation to the next. Therefire, it will improve packaging efficiency.

3. Food processing industry: In food processing production lines, people can use knife-edge conveyors to transport food raw materials or finished products. Because it will ensure a smooth production process.

Precautions

Load capacity: Make sure that the load capacity of the knife-edge conveyor matches the actual weight of the material to be transported to avoid overloading the equipment. Safety, maintenance, load capacity and other factors, we need to consider during use to ensure its effective and safe operation