A chain conveyor can seamlessly shift from horizontal to inclined or even vertical conveyance, an attribute that is invaluable in complex facility layouts. Featuring a durable chain that acts as the medium for material conveyance, this system is particularly recognized for its strong construction and adaptability to diverse industrial tasks.

Description

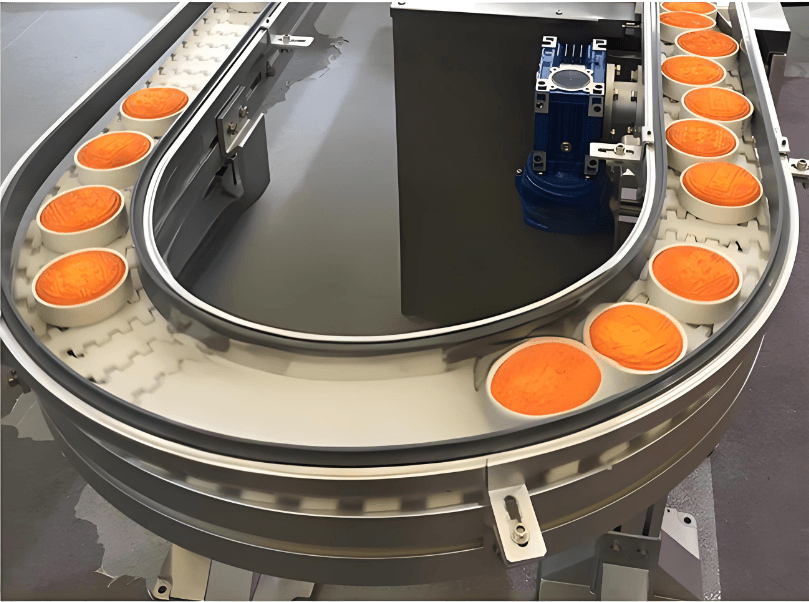

Chain Conveyor System

A chain conveyor, we commonly use as a material transmission equipment with many advantages and functions. Chain conveyor has the advantages of simple and compact structure, which can effectively save space. The connection between its chain and conveying plate is firm and reliable, can withstand large loads, and has high transmission efficiency.

Secondly, chain conveyor has a wide range of applications. And we can use it for the transportation of various types of materials.

Whether it is block materials, powder materials or liquid materials, they can be transmitted by chain conveyors. Freisin, chain conveyors are also stable and reliable. Due to the firm connection between the chain and the conveying plate, it is not easy to loosen and fall off during the transportation process. That can ensure the transmission of materials.

Chain conveyors can also be transported horizontally, inclined and vertically as needed, with greater flexibility. Whether it is long-distance horizontal transmission or high-altitude vertical transmission, chain conveyors can do it. Freisin, chain conveyors can also be linked with other equipment to form a production line. It can realize continuous transmission and automatic operation of materials, and improve production efficiency.

In general, chain conveyors have the advantages and functions of simple and compact structure, wide application range, stability and reliability, high flexibility, and the ability to realize automatic operation.

Composition of Seoltóir Slabhra

A chain conveyor is mainly including chain, sprocket, bearing, drive device, tensioner and conveying trough. Among them, the chain is the most important part. It carries the material and moves forward under the drive of the sprocket. The sprocket is a vital element that works in tandem with the chain, propelling the chain into motion through its rotation.

The bearing and drive device serve the purpose of both supporting the sprocket and enabling its rotation. Meanwhile, the role of the tensioner is to modify the chain’s tension, guaranteeing steady and reliable conveyance. The conveying trough is a container for carrying materials. Besides, we can design it according to needs to meet the conveying requirements of different materials.

Working Principle of Seoltóir Slabhra

The working principle of chain conveyor is mainly to realize material conveying through the circular motion of chain. Specifically, the chain moves forward at a certain speed under the drive of sprocket to convey the material from the feed port to the discharge port. In this process, the material moves together with the conveying trough, thereby realizing the continuous conveying of the material.

1. Power transmission: The power transmission of chain conveyor mainly depends on the meshing action between sprocket and chain. When the motor drives the sprocket to rotate through the reducer, the sprocket drives the chain to rotate. Thereby realizing the transmission of power.

2. Material conveying: The conveying of materials in chain conveyor mainly depends on the driving action of chain. When the chain moves under the drive of sprocket, the material on the chain also moves with it. Thereby realizing the continuous conveying of materials. In order to ensure the stable conveying of materials, the design of conveying trough is also very critical.

Generally speaking, people can design the shape and size of the conveying trough according to the characteristics of the material and the conveying requirements to achieve the best conveying effect.

Other Working Principles

3. Tension adjustment: In chain conveyor, the adjustment of tension is very important. Appropriate tension can ensure good meshing between the chain and the sprocket. And can also reduce vibration and wear during equipment operation. The function of the tensioning device is to adjust the tension of the chain to keep it within the appropriate range.

When the chain is worn or stretched, the tensioning device can automatically adjust the length of the chain to ensure the normal operation of the equipment.

4. Maintenance: In order to ensure the normal operation and service life of the chain conveyor, regular maintenance is essential. The content of maintenance includes checking the wear of key components such as chains, sprockets, bearings, etc..

And replacing severely worn parts in time; regularly cleaning residual materials inside the equipment to prevent blockage and wear; regularly lubricating moving parts. Such as bearings and sprockets to reduce wear and friction resistance, srl.

In Conclusion

In summary, the industrial chain conveyor is a highly advantageous and versatile material handling solution. It is special in its simple, space-saving structure, reliable transport mechanism, and efficient performance. It is capable of handling a variety of materials, including solid blocks, powders, and liquids. That makes it suitable for a broad range of applications.

The system’s flexibility in terms of direction of conveyance — horizontal, inclined, or vertical. It allows for adaptability in complex material handling scenarios. Furthermore, chain conveyors can be integrated into production lines for continuous and automated operations, enhancing overall productivity.

The system’s composition, with crucial elements like the chain, sprocket, bearing, drive device, tensioner, and conveying trough. Therefore, that ensures it performs its primary function of moving materials smoothly and uniformly from one point to another. Proper tension adjustments and regular maintenance, involving inspections, cleaning, and lubrication, are essential for the longevity and consistent operation of the conveyor.

All these attributes of the chain conveyor system underscore its importance and efficiency. Because it is a key component in modern industrial operations.