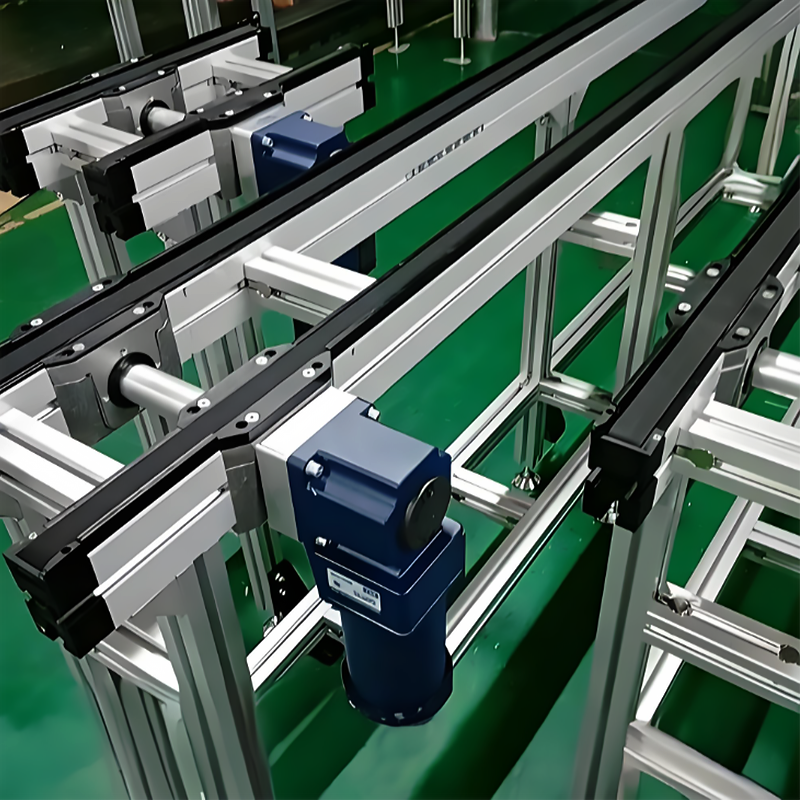

Our Pallet Conveying Systems are designed to streamline your material handling processes with efficiency and reliability. These modular systems can accommodate various pallet sizes and weights, making them perfect for diverse industrial applications.

Featuring energy-efficient drive technology and easy installation, our conveyors enhance workflow, reduce manual labor, and ensure optimal product protection. Transform your operations with our innovative pallet conveying solutions today!

Description

The Essential Guide to Pallet Conveying Systems

Introduction

In the modern society, efficiency is the heart of success. As businesses strive to optimize their operations, the importance of effective material handling systems cannot be overstated. So pallet conveying systems play a pivotal role in ensuring smooth internal transportation processes.

These systems not only enhance productivity but also ensure the safety and integrity of products. In this article, we will delve into the features, benefits, applications, and considerations when investing in pallet conveying systems.

What is a Pallet Conveying System?

A pallet conveying system is a specialized mechanism designed to transport pallets within a facility. So they provide an efficient means to move goods between production, storage, packing, and shipping areas, significantly reducing the time and effort required for manual transport.

Pallet conveyors can be classified into several types, including roller conveyors, belt conveyors, chain conveyors, and more. Besides, each type has its unique advantages, making it crucial to select the right system based on your specific operational needs.

Key Features of Pallet Conveying Systems

Modular Design

One of the standout features of pallet conveying systems is their modular design. So this flexibility allows businesses to customize the system to fit their specific layout and operational requirements. You can easily expand or reconfigure the system as your needs change, making it a future-proof investment.

Energy Efficiency

Modern pallet conveying systems often incorporate energy-efficient technologies, such as frequency-controlled drive systems. These systems adjust power usage based on the load and speed, significantly reducing energy consumption. As a result, businesses can lower their operating costs while also contributing to sustainability efforts.

Versatility

Pallet conveying systems are designed to handle various pallet sizes, types, and weights. Whether you are transporting lightweight consumer goods or heavy industrial pallets, these systems can accommodate your needs. Therefore, this versatility makes them suitable for diverse industries, from food and beverage to automotive manufacturing.

Ease of Installation and Maintenance

The design of pallet conveying systems allows for quick installation and straightforward maintenance. Many systems come pre-assembled, reducing setup time. Additionally, the user-friendly design facilitates easy access to components for routine maintenance, ensuring minimal downtime and maximizing productivity.

Benefits of Using Pallet Conveying Systems

Improved Efficiency

Automating pallet movement decreases the dependence on manual labor, resulting in quicker transportation processes. By streamlining operations, businesses can increase throughput and reduce bottlenecks, ultimately enhancing overall efficiency.

Increased Safety

Safety is a top priority in any workplace. Pallet conveying systems minimize the risk of workplace injuries associated with manual handling. By automating the transport of heavy loads, employees can focus on more critical tasks, reducing the likelihood of accidents and injuries.

Optimal Material Flow

Pallet conveying systems ensure that materials move seamlessly through the production process. This leads to better organization and a more streamlined workflow. With efficient material handling, businesses can reduce lead times and improve customer satisfaction.

Enhanced Product Protection

One of the key advantages of pallet conveying systems is their ability to maintain product integrity during transportation. With gentle handling and precise movement, these systems help prevent damage to goods, ensuring that products arrive in optimal condition.

Applications of Pallet Conveying Systems

Manufacturing Plants: In manufacturing environments, pallet conveying systems facilitate the flow of materials between production lines. Besides, they enable just-in-time manufacturing by ensuring that raw materials are readily available when needed.

Warehouses: In warehouses and distribution centers, pallet conveyors streamline the storage and retrieval of pallets. So they make it easier to manage inventory and improve order fulfillment processes, resulting in faster shipping times.

Food and Beverage Industries: In food processing and beverage production, maintaining hygiene is critical. Pallet conveying systems provide a safe and efficient means of transporting goods while adhering to strict sanitation standards.

Retail Distribution: In retail settings, pallet conveyors support the logistics of palletized goods for shipping to stores. Therefore, they enhance the efficiency of loading and unloading processes, ultimately speeding up the supply chain.

Considerations When Investing in Pallet Conveying Systems

Before investing in a pallet conveying system, several factors should be considered:

Space Availability: Assess the available space in your facility to determine the appropriate layout for the conveyor system. A well-planned layout can maximize efficiency and minimize congestion.

Load Specifications: Understand the types of pallets and loads you will be handling. This information will assist you in selecting the appropriate conveyor system that meets your specific needs.

Integration with Existing Systems: Consider how the new pallet conveying system will integrate with your existing material handling equipment. Compatibility is crucial for a smooth transition and optimal performance.

Future Scalability: Choose a system that can grow with your business. A modular design allows for easy expansion, ensuring that your investment remains valuable as your operations evolve.

Conclusion

In a word, pallet conveying systems are an essential component of efficient material handling in today’s industrial environment. With their modular design, energy efficiency, and versatility, these systems can significantly enhance your internal transportation processes.

By investing in a pallet conveying system, businesses can improve operational efficiency, increase safety, and ensure optimal product protection. If you’re interested in discovering how a pallet conveying system can benefit your operations, contact us today for a consultation!