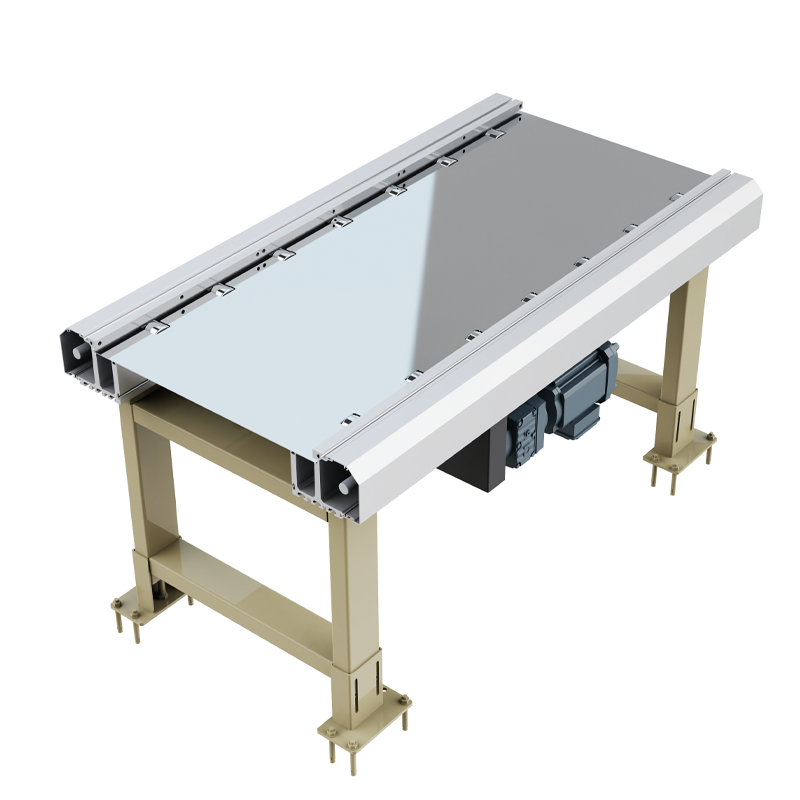

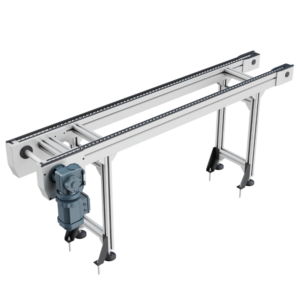

Pallet Conveyors: Streamline your industrial operations with our heavy-duty, adaptable conveyors, geared for precision handling of palletized goods. Durable steel construction and customizable components ensure efficient and reliable transport in demanding environments.

Description

Pallet Conveyors Automation Systems

Pallet conveyors are engineered to seamlessly move substantial loads, enhancing operational efficiency in manufacturing, warehousing, and distribution environments. Toshine tailors cutting-edge technologies to meet the specific needs of your process, ensuring smooth and effective operations.

These conveyors enhance the movement and handling of heavy items, fostering increased throughput and adaptability while reducing operational expenses. Meanwhile, they offer a lift to productivity by creating an ergonomic workflow that minimizes physical strain on operators. Ag Toshine, our team of experts collaborates with you to integrate the perfect solution, be it an isolated conveyor unit or a complex automated material handling ecosystem.

Functionality of Pallet Conveyors:

Pallet conveyors transport heavy or bulky loads with precise control, often situated low for optimal operation. At the same time, these loads are moved via a variety of mechanisms, including belts, slats, rollers, or chains. Synchronizing effortlessly with supplementary pallet equipment, they enhance operations with automated palletizing systems, turntables, wrapping systems, and more.

Pallet conveyors not only facilitate efficient transit between locations but also boast advanced designs for zero-pressure accumulation, employing photo-sensor networks and motor-controlled zones to curb product damage and extend equipment life.

Advantages:

– Streamline facility logistics and reduce vehicle traffic

– Lessen manual handling of heavy loads

– Gentle transport ensures minimal product damage and precise placement

– Boost overall efficiency, safety, and ergonomic conditions

– Allocate fork truck resources to other essential tasks

Considerations:

When seeking the most effective conveyor solution, Toshine’ professionals assess various angles, from turnkey solutions to bespoke configurations, based on:

– The nature, dimensions, and weight of items to convey

– The specific type of pallet or skid required

– Destination points, including the necessity for bends or transfer stations

– Operational procedures, including the extent of starts and stops, and accumulation needs

– The working environment, such as exposure to high temperatures or oily components

– Space within the facility for the conveyor setup

Pallet Conveyors Types

Pallet conveyors are automated logistics equipment used to handle and transport palletized goods. They can be classified according to different designs and functions. Here are some common types of pallet conveyors:

- Chain pallet conveyor: Using chain drive, suitable for carrying heavier palletized goods.

- Roller pallet conveyor: Composed of a series of rotating rollers, relying on gravity or power to drive the pallet to move.

- Belt pallet conveyor: Similar to belt conveyors, but with a fixed pallet position on the load-bearing surface.

- Accumulating pallet conveyor: Can achieve the stacking and sequential transportation of pallets, often used in warehousing and distribution centers.

Other Types

- Electric pallet conveyor: Driven by a motor, the moving speed and direction of the pallet can be precisely controlled.

- Air cushion pallet conveyor: Using the principle of air cushion, achieve the smooth transportation of pallets, suitable for fragile items.

- Curve pallet conveyor: Designed to achieve the turning of pallets during transportation and optimize the spatial layout.

- Telescopic pallet conveyor: we can adjust the length as needed to adapt to different working spaces.

- Vertical conveyor:Used to achieve vertical lifting of palletized goods, often used in multi-storey warehouses.

- Automated Guided Vehicle (AGV) Systems: Although not conveyors in the traditional sense, AGV systems can carry palletized cargo. Besides, it can also navigate autonomously through a factory or warehouse.

- Pallet Lifters: Used to lift pallets to a certain height for easy access to upper shelves.

- Pallet Rotators: Can rotate pallets to change the direction of pallet delivery or to sort cargo.

- Pallet Sorting Conveyors: Integrated with a sorting system that automatically distributes pallets to different exits or areas.

- Modular Pallet Conveyors: Made of modular components that we can quickly assemble and adjust to specific needs.

- Pallet Conveyor Systems: A comprehensive system that may include multiple types of conveyors listed above, as well as control systems and software.

About Pallet Conveyors

All in all, pallet conveyors have widespread applications across diverse sectors of the economy. Include the brewing, beverage, tobacco, pharmaceutical, home appliance, and machinery manufacturing industries. Therefore, these systems are adept at transporting a variety of bulk materials and completed products, either vertically or on an incline, and are also ideal for integrating into production line processes.

As their load-bearing and moving components are constructed from metal, pallet conveyors outperform other types of conveyance equipment in moving heavier, larger, and more abrasive materials or finished goods. Additionally, they are well-equipped to handle materials or completed products at high temperatures, capable of enduring conditions of 600 to 700 degrees Celsius.

The pallet automated conveyor serves as a crucial component within the structure of an automated warehouse, functioning as a conduit that unites different logistical nodes. It plays a key role in bridging connections between personnel and stations, various workstations, as well as between processing and storage, or processing and assembly, all while providing the additional benefits of temporary material storage and buffering capabilities.

Employing the pallet automated conveyor smartly tightens the coordination among diverse operational phases, thereby optimizing production efficiency. So it stands as an essential tool for managing flow within the logistics chain.

Within the automated warehouse’s input-output framework, the roles of the pallet automated conveyor system encompass transportation, intake, processing, and storage of materials. Typically, the system is also to perform tasks like size verification, weighing, and automated identification.