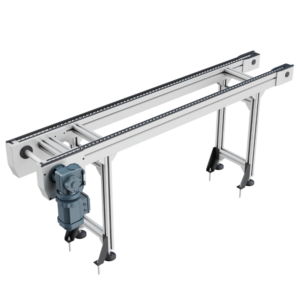

Aluminum Timing Belt Conveyor System is engineered for superior performance in material handling applications. Constructed from lightweight, durable aluminum, this conveyor system is both corrosion-resistant and easy to assemble, making it a cost-effective solution for any production line.

Description

Toshine Aluminum Timing Belt Conveyor Systems

In today’s modern industrial landscape, efficiency and precision are critical for success. The Aluminum Timing Belt Conveyor System is a top choice for companies. Because it can greatly improve their material handling. This conveyor system uses advanced technology and high-quality materials.

It performs exceptionally well in many applications. So this essay will explore the Aluminum Timing Belt Conveyor System. It will discuss its key features, benefits, and uses. Because it is important in today’s manufacturing and logistics.

Product Specification

What Do You Know about Aluminum Timing Belt Conveyor System

The Aluminum Timing Belt Conveyor System moves products through production. It does so efficiently and accurately. By employing a timing belt mechanism, the system ensures that items remain synchronized and move at a constant speed. Besides, the lightweight, durable aluminum frame simplifies assembly. Thus, it allows easy adaptation to different production lines. Besides, this design flexibility makes it suitable for industries ranging from manufacturing to packaging.

Key Features

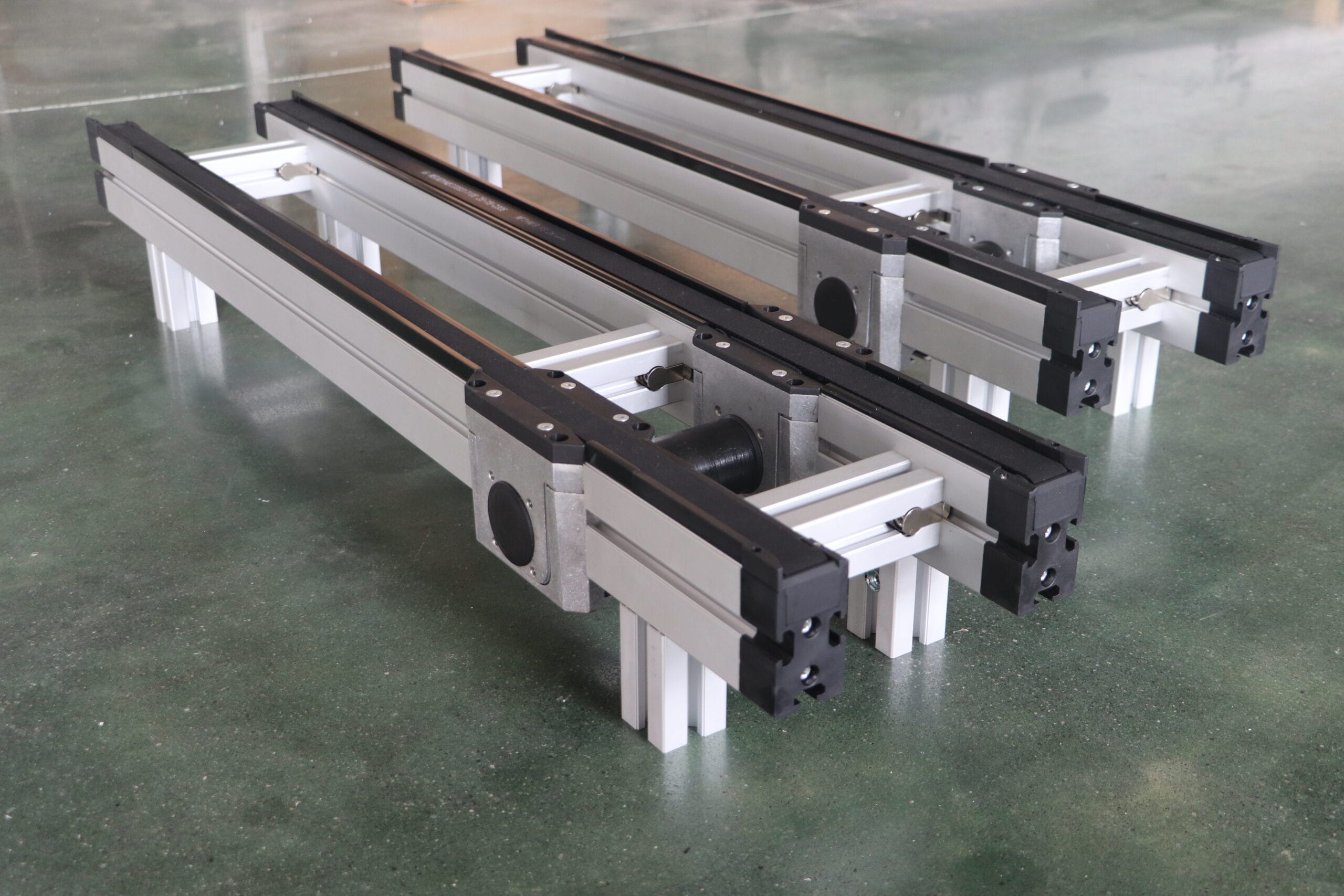

Aluminum Construction

One of the standout features of the conveyor is its aluminum construction. Aluminum is lightweight. Besides, it resists corrosion and wear. So, it is a long-lasting, cost-effective choice for businesses.

Timing Belt Mechanism

The timing belt mechanism ensures precise movement of products along the conveyor. This feature is essential for applications that need high accuracy, such as assembly lines and the transport of delicate items. The timing belt securely holds products in transit, thereby reducing the risk of damage.

Modular Design

The Aluminum Timing Belt Conveyor System features a modular design, which allows for easy customization and expansion. Businesses can adapt the conveyor layout to fit their specific needs—whether that means increasing the length, adding curves, or incorporating more sections. This flexibility is invaluable in dynamic manufacturing environments where processes frequently change.

Ease of Installation and Maintenance

Thanks to its lightweight aluminum frame, installation and maintenance are straightforward. The components are designed for quick assembly, which minimizes downtime during setup. Additionally, the system requires minimal maintenance, allowing businesses to concentrate on productivity rather than upkeep.

Versatile Applications

The conveyor system’s versatility is a significant advantage. It can be utilized across various industries, including food, electronics, automotive, and pharmaceuticals. Besides, this adaptability ensures that it meets the unique needs of different production processes.

Benefits of the Toshine Timing Iompar Crios System

Increased Efficiency

The precise movement provided by the timing belt boosts efficiency. By reducing delays and ensuring smooth product transit, the timing belt conveyor system helps businesses maintain high productivity levels—an essential factor in today’s fast-paced manufacturing environment.

Cost-Effectiveness

The durable aluminum construction and low maintenance requirements make this system a cost-effective choice. By minimizing expenses related to frequent repairs or replacements, the Toshine Aluminum Timing Belt Conveyor System represents a smart investment.

Improved Safety

The timing belt conveyor system incorporates several safety features that protect both products and workers. The timing belt securely holds items in place, which reduces the risk of spills or accidents. Furthermore, the lightweight frame minimizes hazards associated with heavy equipment, ensuring a safer work environment.

Enhanced Product Handling

The timing belt mechanism provides gentle handling of products, making it ideal for transporting delicate or fragile items. So this feature is especially vital in industries like food and electronics, where maintaining product integrity is paramount.

Scalability

As businesses grow, their operational needs may change. The modular design of the Toshine conveyor system allows for easy expansion or reconfiguration. Thus, companies can scale their operations without incurring significant investments in new equipment.

Applications

The Aluminum Timing Belt Conveyor System is highly versatile and suits a wide range of applications:

Manufacturing: It efficiently moves components along assembly lines, ensuring production remains streamlined.

Food and Beverage: The system excels in food processing plants, where hygiene and gentle handling are critical.

Electronics: In the electronics sector, the conveyor system transports sensitive components with care, minimizing the risk of damage during transit.

Pharmaceuticals: The Toshine conveyor system meets stringent pharmaceutical industry standards, facilitating the movement of medications and medical devices.

Conclusion

In conclusion, the Aluminum Timing Belt Conveyor System is an essential tool for businesses aiming to enhance their material handling processes. With its lightweight aluminum frame, precise timing belt mechanism, and modular design, this conveyor system offers outstanding performance and adaptability.

Its benefits—such as increased efficiency, lower costs, and improved safety—make it ideal for various industries. As businesses continually seek innovative production methods, the Aluminum Timing Belt Conveyor System stands out as a reliable and efficient option.