Toothed belt conveyors are a special conveying equipment, mainly used for conveying various items. It has the advantages of wear resistance, long life, low noise and high reliability.

The working principle of toothed belt conveyor is to drive the conveyor belt through the motor, drive the rollers, and the friction between the rollers wraps the belt to achieve the purpose of conveying items. This kind of conveyor is suitable for light industrial fields, such as the electronics industry.

Description

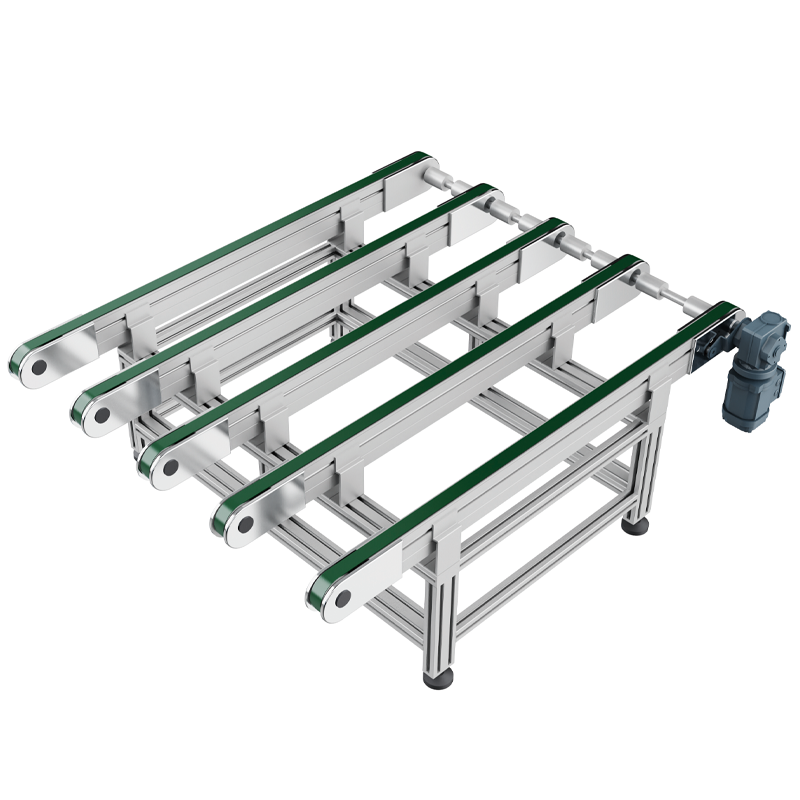

Toshine Toothed Belt Conveyor System

Toothed Belt Conveyors

Toothed belt conveyors, people know them for their exceptional positioning accuracy. Thanks to the toothed belts and pulleys, these conveyors can operate at high speeds while remaining quiet. Besides, they allow for effective acceleration and deceleration of the conveyed materials.

This type of conveyor is especially well-suited for transporting goods with large surface areas and strong dimensional stability. For sensitive items, the timing belt conveyor is a better choice compared to more robust chain conveyors. So it offers excellent damping and variable surface properties for gentle handling.

Toothed Belt Conveyors Advantages at a Glance:

- Low-Wear Design: People can guide toothed belts on a durable plastic strip, minimizing wear and tear.

- Customizable Surfaces: People can tailor the timing belt to your specific needs, featuring options. Like adhesive coatings for better grip, heat-resistant materials, and drivers.

- Adjustable Configurations: Toothed belt strands can be driven individually or coupled together. Besides, it is with height and width easily adjustable through electromechanical or pneumatic systems to suit various operating conditions.

- Versatile Material Handling: Suitable for a wide range of material dimensions, accommodating diverse applications.

- Tailored Solutions: We can design and produce each conveyor according to your specific requirements.

- Low Maintenance: High-quality toothed belts and a well-thought-out drive design ensure minimal maintenance.

Choose Toshine’s toothed belt conveyors for reliable, efficient, and customizable material handling solutions!

What is a Pallet Transfer System?

A pallet transfer system consists of a dual toothed belt setup where individual transfer plates or product carriers operate at speeds of up to 65.61 feet per minute. Available in three different sizes, this system offers optimal configurations for various applications.

The transfer plates or product carriers are available in six different sizes. And they can support loads of up to 37 pounds. People can also equip them with RFID technology for easy identification at any time. Designed to meet customer specifications, the system includes two types of drive controllers to regulate speed effectively.

Movement of the transfer plates or product carriers can be directed using lateral transport, 90° deflection, 180° deflection, or a switch. A shock-absorbing pneumatic separating unit or stopper is utilized to stop, separate, and decelerate one or more incoming workpiece carriers. Thanks to the dovetail guide, we can easily reposition all components.

Advantages

Simple Structure: The flat belt design is straightforward, making installation, operation, and maintenance easy. Therefore, this simplicity translates to cost-effectiveness across many industries.

Cost-Effective: Compared to other conveyor types, flat belt conveyors have lower manufacturing and maintenance costs. So they are especially suitable for small to medium-sized enterprises or applications that require numerous conveyor systems.

Wide Applicability: Besides, these conveyors can transport various materials, including bulk, light, and medium-weight items. Therefore, their adaptability allows them to handle products of different shapes and sizes.

Low Noise: Operating smoothly with minimal noise, flat belt conveyors are ideal for production environments where sound control is crucial.

High Flexibility: People can customize them in different lengths and widths to fit various production line layouts. Besides, people can configure them for horizontal or inclined transport as we need.

Easy Maintenance: Their simple design makes maintenance straightforward, and belt replacement is convenient, reducing downtime.

Application Fields

- Manufacturing Industry: Commonly used in assembly lines, inspection lines, and packaging lines for material transport and product handling in electronics, automotive parts, and household appliances.

- Food Processing: Widely used for transporting, packaging, sorting, and processing food products, flat belt conveyors often feature food-grade materials. So they are easy to clean, and meet hygiene standards.

- Packaging Industry: Essential for transporting products, packaging materials, and finished goods, especially in environments that require continuous and efficient operations for bottled, boxed, and bagged products.

- Logistics and Warehousing: Employed for sorting, handling, and loading/unloading various packages, boxes, and pallets, helping to improve operational efficiency in logistics and warehousing centers.

- Printing Industry: Used for transporting paper, books, packaging boxes, and other items, facilitating efficient production line operations in the printing and paper processing industry.

- Chemical and Pharmaceutical Industry: Ideal for transporting powders, granules, bottled, or packaged products, these conveyors are suitable for clean environments with strict hygiene requirements.