7 Tendenze emergenti che modellano l'automazione industriale in 2025

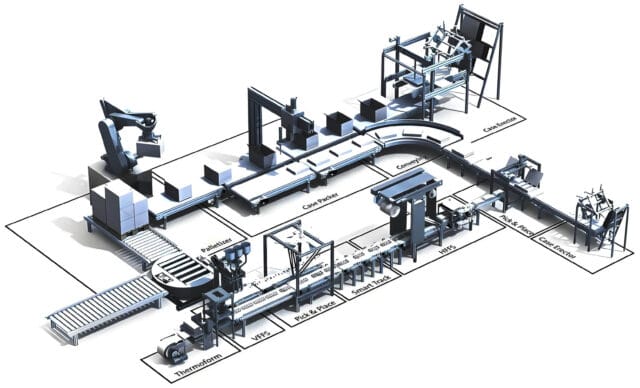

Il settore dell'automazione industriale sta subendo la sua fase più trasformativa da decenni. Mentre i produttori affrontano pressioni per operazioni sostenibili, linee di produzione flessibili, e miglioramenti della sicurezza della forza lavoro, Le soluzioni di gestione dei materiali innovativi stanno diventando differenziati critici. Esploriamo le tendenze chiave che guidano le innovazioni del sistema di trasporto:

1. Sustainable Manufacturing Demands

Modern conveyor systems now play a dual role in production efficiency and environmental compliance. Your pallet conveyors and roller conveyors can now be equipped with:

- Energy-recovery systems in belt conveyors

- Low-friction roller designs reducing power consumption by up to 30%

- Recyclable chain components in chain conveyor systems

2. AI-Enhanced Predictive Maintenance

The integration of smart sensors in our conveyor solutions enables:

- Real-time monitoring of chain tension in chain conveyors

- Vibration analysis for roller conveyor bearings

- Predictive replacement alerts for belt conveyor wear parts

3. Collaborative Robotics Integration

Modern safety guard fencing solutions now feature:

- Modular designs compatible with mobile robot workcells

- Smart safety curtains that adapt to collaborative robot speeds

- Integrated access platforms (industrial step platforms) for hybrid human-robot workspaces

4. Digital Twin Implementation

Our conveyor system designs now support:

- Virtual commissioning of complete pallet conveyor networks

- Physics-based simulations for roller conveyor load testing

- Wear pattern predictions for chain conveyor components

5. Supply Chain Resilience Strategies

Modular conveyor components enable:

- Rapid reconfiguration of roller conveyor layouts

- Scalable extension of belt conveyor lines

- Standardized safety guard fencing systems for fast facility expansions

6. Workforce Safety Innovations

Next-gen protective solutions include:

- Anti-microbial coatings on industrial step platforms

- Smart lighting integrated into pallet conveyor pathways

- Ergonomic access points in roller conveyor maintenance zones

7. Upskilling Through Automation

Our systems support workforce development with:

- AR-assisted maintenance guides for chain conveyor repairs

- Virtual training modules for belt conveyor troubleshooting

- IoT-enabled diagnostic tools for roller conveyor technicians

Why Modern Trasportatore Systems Matter More Than Ever

As production lines face demands for:

- 35% faster changeovers (achievable through modular roller conveyors)

- 50% reduction in downtime (enabled by smart chain conveyor monitoring)

- 100% safety compliance (ensured by next-gen guard fencing systems)