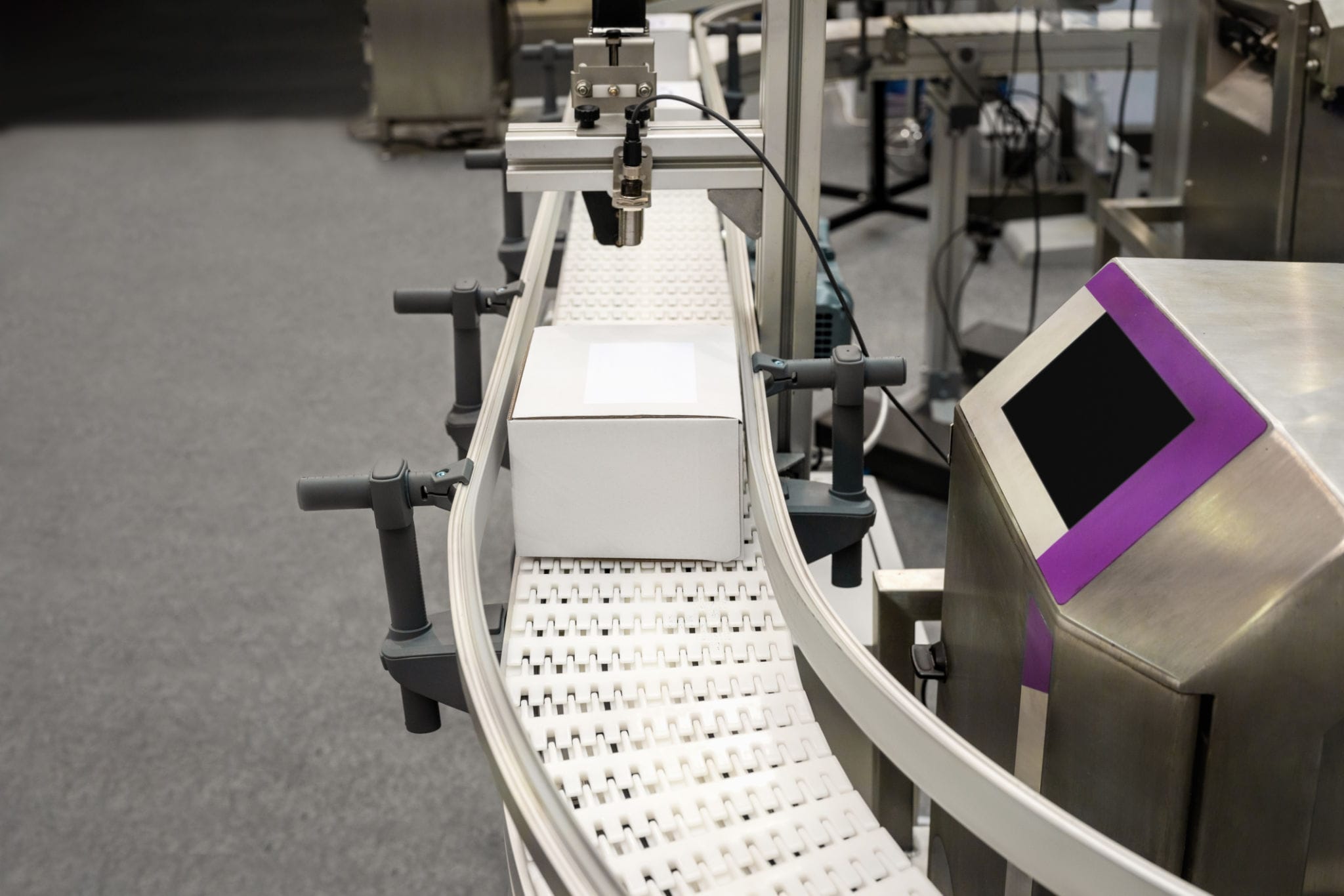

Our flexible chain conveyor is a versatile material handling solution designed to transport products in a variety of shapes, dimensioni, and configurations. Ideal for industries such as food processing, prodotti farmaceutici, and manufacturing, this conveyor system can navigate tight spaces, turn corners, and move both horizontally and vertically.

With a modular design, people can easily customize it to fit any layout and adapted to changing production needs. Durable and low-maintenance, it offers reliable performance while reducing energy consumption.

Descrizione

The Advantages of Flexible Chain Conveyors for Modern Industries

Introduction

Flexible chain conveyors are rapidly gaining popularity in various industries. And it is because their ability to adapt to complex layouts and diverse material handling needs. People can use these versatile systems for a wide range of applications. It is including food processing, prodotti farmaceutici, electronics manufacturing, and automotive assembly.

In this essay, we will explore what flexible chain conveyors are, their advantages, key features, and how they are transforming industries across the globe.

What Are Flexible Chain Conveyors?

A flexible chain conveyor is a type of conveyor system. And the system uses a chain belt to transport products along a defined path. Unlike traditional conveyors that operate in straight lines, flexible chain conveyors can be configured to handle curved, inclined, and vertical transport. The chain material is plastic or metal links. People can easily connect to form longer sections or adjust to fit specific transportation needs.

These conveyors are modular, meaning we can customize and reconfigure as per the operational requirements of the factory or warehouse. These conveyors work well for industries that deal with different sizes, weights, and shapes of products.

Advantages of Flexible Chain Conveyors

Versatility in Layout Design

One of the main advantages of flexible chain conveyors is their ability to adapt to various layouts. Unlike traditional conveyors, which are limited to linear paths, flexible chain systems can navigate corners, change directions, and even move vertically. This allows for more efficient use of space in warehouses, production lines, and processing plants.

Per esempio, in food manufacturing, flexible chain conveyors can be routed through narrow spaces. So that will ensure that it can transport products without taking up excessive floor space. Similarly, in automotive assembly lines, these conveyors can transport parts in a zigzag pattern, reducing the need for large, bulky conveyor systems.

Modularity and Customization

Flexible chain conveyors are modular, meaning that people can build the system for specific needs and easily expand or adjust over time. As production lines evolve or as space requirements change, the conveyor system can be reconfigured without the need to install a brand new conveyor.

This customization is especially important for industries with evolving production processes or where the handling of different products is in a need. Manufacturers can tailor their conveyor systems to meet specific operational goals in speed, product variety, or the handling of more fragile items.

More about Advantages

Durability and Maintenance

Flexible chain conveyors are known for their durability and low maintenance requirements. The chain links’ design can withstand heavy loads and high-frequency use without wearing out quickly. Inoltre, plastic chains are corrosion-resistant, making them ideal for environments where moisture or chemicals may be present.

Maintenance of flexible chain conveyors is relatively simple. The modular design allows for easy replacement of bad links or components. That will reduce downtime and ensure that the conveyor system operates smoothly.

Improved Productivity and Efficiency

The flexibility and reliability of flexible chain conveyors translate into higher productivity and efficiency on the factory floor. With the ability to handle products in various shapes and sizes, these conveyors can improve throughput by moving products more quickly and smoothly through production lines.

Flexible chain conveyors also allow for continuous transport, reducing the need for manual handling. In industries like food processing or pharmaceuticals, where hygiene is critical, minimizing human intervention is a key advantage. The streamlined movement of products ensures that operations run smoothly, and the risk of product damage or contamination is reduced.

Energy Efficiency

Another great thing about flexible chain conveyors is that they use energy efficiently. We can design many systems to operate using less power compared to traditional conveyor types. Thus, that makes them more environmentally friendly and cost-effective. The use of lightweight materials and advanced motor technologies helps reduce energy consumption. So it is particularly important in industries looking to lower operational costs.

Applications of Flexible Chain Conveyors

People can use flexible chain conveyors in a variety of industries, each benefiting from the unique features of these systems. Here are some common applications:

- Food Processing: Flexible chain conveyors are ideal for moving food products through different stages of production. They can handle irregularly shaped items, such as fruits or bakery goods, without damaging them. Inoltre, their ability to navigate tight spaces and corners allows food production lines to run more efficiently.

- Pharmaceuticals: In the pharmaceutical industry, flexible chain conveyors help transport sensitive items like medicine bottles, blister packs, or vials. Oltretutto, the modular design ensures that it can move products smoothly through different phases of production without contamination.

- Electronics Manufacturing: People can use these conveyors in electronics manufacturing to move components along the production line. Their ability to handle small, delicate parts with precision makes them indispensable in this high-tech sector.

- Automotive Assembly: Flexible chain conveyors are very popular in automotive manufacturing to transport parts and components in a flexible yet controlled manner. They can be routed around machinery and equipment, saving space and improving assembly efficiency.

Conclusion

Flexible chain conveyors are transforming material handling across industries, offering unmatched versatility, efficienza, and customization. Their ability to handle complex layouts, improve productivity, and lower maintenance costs. So it makes them an attractive choice for modern manufacturing environments.

Whether in food processing, prodotti farmaceutici, or automotive assembly, these conveyors are proving to be invaluable tools for businesses looking to optimize their production lines. As industries continue to evolve, flexible chain conveyors will undoubtedly play a crucial role in shaping the future of material transport systems.