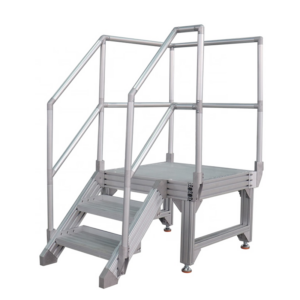

Aluminum stairs and platforms boast a sleek and modern design. The lightweight aluminum construction not only enhances their aesthetic appeal but also offers corrosion resistance, ensuring long-lasting performance even in harsh conditions. With minimal maintenance requirements, our products enable you to focus on your core operations without interruptions.

Descrizione

Toshine Aluminum Stairs and Platforms

Aluminum stairs and platforms are a good tool for high-altitude employment in production workshops. According to the customer’s use requirements, we can customize different structures, including movable, fixed, small, large, and we can customize the largest as a bridge.

Aluminum stairs and platforms are a large-scale climbing work platform used in factory workshops. So it is mostly including heavy industrial aluminum profiles with patterned aluminum plates and anti-skid plates. Designed and constructed on demand, it is easy to disassemble and assemble, beautiful and durable. It is one of the more popular factory climbing work platforms.

Perciò, aluminum stairs and platforms are a good tool for high-level employment in production workshops. According to the customer’s use requirements, we can customize different structures, movable, fixed, small, large, and the largest, we can customize as a skybridge.

Aluminum stairs and platforms are a large-scale climbing work platform used in factory workshops. Oltretutto, it is mostly made of heavy industrial aluminum profiles with patterned aluminum plates and anti-skid plates. Designed and constructed on demand, easy to disassemble and assemble, beautiful and durable. Oltretutto, it is currently one of the more popular factory climbing work platforms.

What should We Know When Customizing Aluminum Stairs and Platforms with Industrial Aluminum Profiles?

Aluminum stairs and platforms do not have fixed specifications and sizes. So users can select and customize according to their actual needs. (Tip: Brillare, an industrial aluminum profile processing plant, can customize non-standard aluminum profile inspection platforms and step ladders on demand.) When customizing aluminum profile walkways and steps, pay attention to the following points:

1. Material selection: Industrial aluminum profiles have a variety of specifications. So people use different aluminum profiles in different places. Per esempio, when customizing an aluminum profile walkway, the profile of the main load-bearing structure should try to choose large-size aluminum profiles, such as 90 series and 100 series aluminum profiles.

The profiles of the guardrail and pedal parts can be slightly lighter aluminum profiles. Such as 3030 industrial aluminum profiles and 4040 Profili di alluminio. The aluminum profile walkway made of this material has good strength, light weight, safety and convenience.

2. The inclination angle of the step stairs: customized according to the actual situation, generally the ladder inclination angle ranges from 45 degrees to 60 degrees. The 45-degree angle is more ergonomic and easy to climb up and down. And 60 degrees is a better angle when the use space is relatively limited.

Others We Need Care

3. The distance of the step ladder: The depth of the step ladder must be at least 220mm, and the width can be selected as 600/800/1000mm. Oltretutto, the aluminum stairs and platforms within this range can be climbed up and down comfortably.

4. Pedal/anti-skid plate selection: The material selection of pedal anti-skid plate is mostly aluminum alloy stripe plate, anti-skid grade R10, generally anti-skid. Aluminum alloy grating plate, anti-skid grade R12, suitable for industries with higher anti-skid grade. There is also an aluminum alloy crocodile mouth perforated plate with anti-skid grade R13, which is suitable for occasions with a lot of oil.

5. The span and load-bearing of aluminum profile walkway: If the span is large, more load-bearing support should be added. If the conditions do not allow for additional load-bearing support, people should use large-size aluminum profiles should for processing. Otherwise the aluminum profile is prone to bending and deformation.

What are the Advantages of Aluminum Stairs and Platforms?

Industrial aluminum profiles, we can make them into a variety of products. Such as non-standard aluminum profile frames, aluminum profile workbenches, equipment hoods, safety fences, industrial aluminum stairs and platforms, stair treads, eccetera.

Advantages of aluminum profile stair treads:

1. Aluminum profiles come in a variety of specifications, and we can select different aluminum profiles for assembly according to the span and load-bearing capacity of the stair treads.

2. There is no limit on the specifications of the stair treads, and people can customize them according to actual needs.

3. Because industrial aluminum profile accessories are installed and locked, no welding, the installation is flexible, the disassembly is convenient, and it is sturdy and beautiful.

4. People can install casters, so can flexibly move, unlike traditional stair treads that we cannot move.

5. The structure is sturdy, corrosion-resistant, wear-resistant, and rust-free, and no maintenance. So it is suitable for multiple production workshops and large-scale mechanical equipment as an inspection platform.

Notes

1. Material selection

Different application sites require different aluminum profiles. As aluminum stairs and platforms need to bear a lot of weight, we usually customize them with profiles of 4040 or above.

If the span is relatively large, people can select profiles of 8080 or above. And that can bear more than 3,500 kg.

2. Inclination angle of step stairs

The inclination angle of the aluminum stairs and platforms, we can decide according to the size of the site and the usage scenario. Generalmente, the inclination angle of the ladder is between 45 degrees and 60 degrees.

3. Selection of anti-skid plates

The main function of anti-skid plates is to prevent slipping. The material of anti-skid plates is mostly aluminum alloy plates.

4. Span and load-bearing capacity

If the span of the aluminum stairs and platforms is relatively large, it needs to add more load-bearing capacity for support. We can process it with large-size aluminum profiles. If the span is too large and the support is too little, the aluminum profiles are prone to bending and deformation.