Pallet conveyor system is an important industrial automation equipment, and there are many advantages for it. People can use it in many fields. a pallet conveyor system plays a vital role in enhancing efficiency and productivity within modern warehouses and manufacturing environments. By facilitating the safe and effective movement of heavy loads, these systems streamline logistics processes and reduce manual handling risks.

With various options available, including overhead, rullo, and high-speed conveyors, businesses can customize their systems to meet specific operational needs. Investing in a well-designed pallet conveyor system not only improves material flow but also minimizes downtime and maintenance costs. As industries continue to evolve, adopting advanced pallet conveyor technology will remain essential for maintaining a competitive edge and achieving sustainable growth

Descrizione

Toshine Motorized Trasportatore di pallet System

Efficient Pallet Conveyor Design for Material Flow

Toshine is leading the way in pallet conveyor technology. Our advanced conveyor systems are designed to handle heavy loads, including pallets and mesh boxes. With a modular design, our solutions provide flexibility and can customize to fit your specific needs. By emphasizing durability and efficiency, our conveyor technology helps lower your total cost of ownership.

We continuously enhance our systems by incorporating the latest technology. So this commitment allows us to streamline logistics processes and ensure a smooth flow of materials. Our pallet conveyor solutions are easy to maintain, reliable, and environmentally friendly. Perciò, that will make them a wise investment for the future. So experience the advantages of efficient and sustainable internal logistics with Toshine.

Optimized Routing and Congestion Management

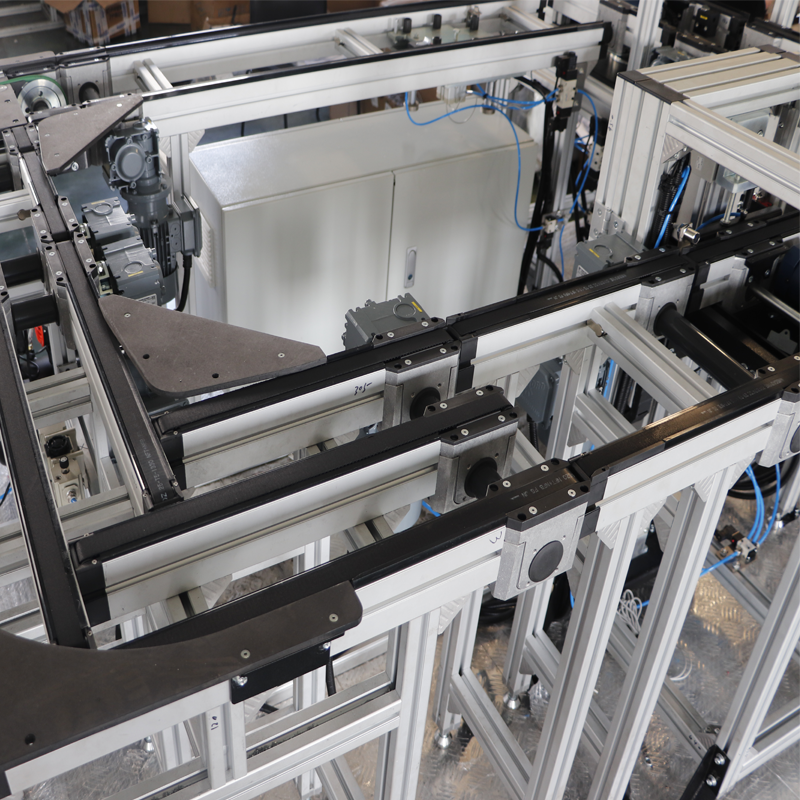

In intralogistics, effective routing and congestion management are essential for maintaining a smooth flow of materials. So Toshine offers customized solutions to address these challenges through our innovative pallet conveyor technology. Oltretutto, our product range includes link conveyors, chain conveyors, and roller conveyors, all specifically designed to safely transport and store pallets. Perciò, these robust components form the backbone of many conveyor systems, ensuring reliability and performance.

A standout feature of our technology is the 90° transfer unit. This unit allows for flexible and space-efficient changes in pallet transport direction without disrupting material flow. It is especially useful in complex logistics environments where efficient space utilization is critical.

Our technologies are crafted to maximize operational efficiency while minimizing operating costs. By combining high-quality components with smart design, Toshine provides conveyor solutions that enhance performance and ensure a long service life with a low total cost of ownership.

Precise Lifting and Turning in Pallet Conveyor Technology

The safe and efficient lifting and turning of pallets is a common challenge in warehouses and production settings. So Toshine addresses this need with a comprehensive range of lifting and turning systems known for their precision and reliability. Our vertical conveyors and console lifters enable vertical transport of loads across multiple levels. Nel frattempo, our turntables and rotary lift tables allow for flexible alignment of pallets in the desired direction.

These components are particularly valuable in environments where space is limited and efficiency is vital. They can be easily integrated into existing conveyor systems, providing reliable solutions for lifting and rotating loads while ensuring continuous material flow. The modular design and adaptability of these systems allow for configurations tailored to your specific operational needs.

A Toshine, we understand the importance of flexibility and efficiency in modern intralogistics. Our lifting and turning systems are designed to meet these demands while ensuring the durability and operational reliability you expect from our products. With Toshine’s advanced solutions, you can trust that your pallet conveyor technology is state-of-the-art, providing you with a significant competitive edge.

How Fast do Conveyors Move?

Conveyor speeds can vary based on the application, but here are some typical examples:

- Unit Handling Conveyors: The standard speed is 65 feet per minute (FPM), which is similar to the pace of a person walking while carrying a 50-pound box. This speed works well for many order picking and assembly tasks.

- Pallet Conveyors: Common speeds include 30, 45, E 60 FPM.

- Overhead Conveyors: These conveyors typically operate at speeds ranging from a few inches per minute to 60 FPM. For comfortable interaction, a speed of 40 FPM or less is recommended for operators.

- High-Speed Conveyors: These conveyors can function at speeds exceeding 300 FPM, with some capable of reaching over 500 FPM.

- Sorter Conveyors: These can achieve speeds of up to 650 FPM.

Conveyor speeds can be customizable to fit the specific needs of each application. Per esempio, a high-speed bottling line will require much faster speeds compared to a conveyor that moves at an average walking pace.

How Long do Conveyors Last?

The lifespan of a conveyor belt can range from a few weeks to over 10 years. Here are several factors for this change, including:

- Usage: The intensity of use, such as speed, length, loading, and strength.

- Product: The type of materials you convey.

- Operating Environment: The conditions in which the belt operates.

- Belt Quality: The quality of the rubber, fabric layers, and fillers used in the belt’s construction.

- Maintenance: The level of upkeep the conveyor receives.

- Design: The effectiveness of the conveyor’s design.

To help extend the life of your conveyor belt, consider these tips:

- Reduce Speed: Running the conveyor at a slower pace can decrease wear and tear.

- Increase Belt Width: A wider conveyor can improve durability and longevity.

- Add Drive Flights: Installing additional drive flights can enhance the lifespan of the conveyor.

- Inspect Regularly: Frequently check the belt’s surface and edges for cracks, scrapes, or deep longitudinal scars.

- Keep Spare Parts: Maintain a stock of spare parts and replace them when you notice signs of wear.

- Perform Regular Maintenance: Follow maintenance guidelines to avoid operational disruptions, breakdowns, and other issues.