How to Adjust a Conveyor Belt?

1. Adjustment of the deviation of the head

This method can be used for deviation caused by any reason. It is to adjust several groups of rollers adjacent to the drum, that is, push several groups of rollers in the deviation direction forward (belt running direction), and push forward to the direction in which it runs. Or retreat to the other side for the same effect. It should be noted during the adjustment that the adjustment of each group of rollers should be as small as possible, but the number of adjustments can be more. At the same time, the adjustment should be made while observing to prevent excessive.

2. Adjustment of the deviation of the middle part of the belt

The deviation of the middle part of the belt is related to the installation accuracy, the center of gravity of the material, etc., but it can be adjusted by this method regardless of any reason. That is, whichever side the belt runs to, push the roller bracket on that side forward (belt running direction). During the adjustment, as mentioned above, try to adjust as many as possible, and the single adjustment range should be as small as possible. During the adjustment, observe the movement of the belt to the middle. After a few turns of operation, if the belt runs well, tighten the roller bracket bolts.

Other Ways

3. Adjustment of tail belt deviation

The adjustment of tail belt deviation is the simplest. Just tighten the adjustment bolt on the side where the belt runs, that is, tighten the belt on that side.

4. Adjustment of belt deviation caused by material deviation

Material deviation means that the material dropped onto the belt is not in the center of the belt conveyor. But is biased to one side, causing the belt to deviate. Hoc tempore, the material can be centered by adjusting the valve or the material outlet, so that the belt will return to the correct direction. If there is still a difference, the roller bracket can be adjusted to make the belt run in the center.

5. The adjustment method for the deviation of the return belt is the same as the above adjustment method.

6. There will be different forms of belt deviation in production. If it is not too serious, try to use self-aligning rollers for adjustment. Push up the roller on the side where the belt deviates.

In conclusione

In short, belt deviation is common in production. This method is simple and clear to adjust. There is no need to consider the cause. It works immediately. In order to ensure that the belt can serve production well, several issues should be noted during the replacement or use of the belt. First of all, when replacing the belt, prevent the belt that is tight on one side and loose on the other side from entering the production line; the belt interface should be straight and not skewed.

During operation, foreign matter and mud adhered to the rollers and rollers should be cleaned in time, and the burrs that are torn or pulled should be cut off in time. The rollers with problems should be replaced in time, etc. At the same time, readers are reminded that if there is anything inappropriate in the text, please criticize and correct it.

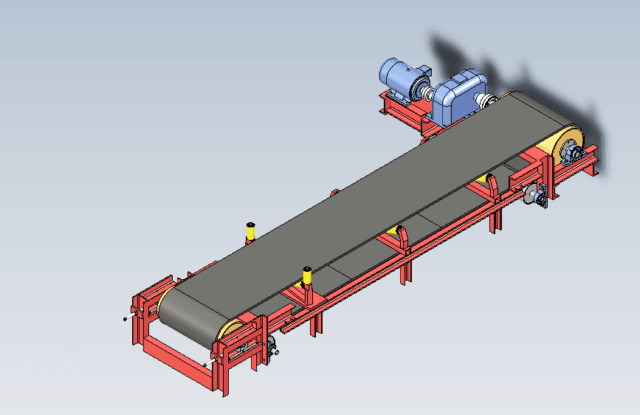

What is a Conveyor Belt?

Conveyor belts and belt conveyors are widely used in agriculture, industrial and mining enterprises and transportation industries to transport various solid block and powder materials or finished items. They can transport continuously, efficiently and at a large angle. Conveyor belts are safe to operate, easy to use, easy to maintain, low freight, and can shorten the transportation distance, reduce the project cost, and save manpower and material resources.

Uses

Oil-proof conveyor belt, anti-skid conveyor belt, climbing conveyor belt, acid-base and heat-proof conveyor belt, cold-proof conveyor belt, flame-proof conveyor belt, corrosion-resistant conveyor belt, moisture-proof conveyor belt, low-temperature conveyor belt, high-temperature conveyor belt, oil-resistant conveyor belt, heat-resistant conveyor belt, cold-resistant conveyor belt, low-temperature resistant conveyor belt, high-temperature resistant conveyor belt, acid-base resistant conveyor belt, flame-retardant conveyor belt.

Material of Conveyor Belt

PVC conveyor belt, PU conveyor belt, polyethylene conveyor belt, plastic chain conveyor belt, modular mesh conveyor belt, polypropylene conveyor belt, nylon conveyor belt, Teflon conveyor belt, stainless steel conveyor belt.

Heat resistance

① Heat-resistant conveyor belt: TI type is not more than 100 degrees. T2 type is not more than 125 degrees. T3 type is not more than 150 degrees

② High temperature resistant conveyor belt: temperature resistance is not more than 200 degrees

③ Burning resistant conveyor belt (metal mesh conveyor belt): temperature resistance 200-500 degrees

The fundamental reason for the belt deviation is that the resultant force of the external force on the belt in the belt width direction is not zero, or the tensile stress perpendicular to the belt width direction is uneven. That causes the roller or drum to produce a component force to one side of the belt’s reaction force. And also causes the belt to deviate to one side under the action of this component force.