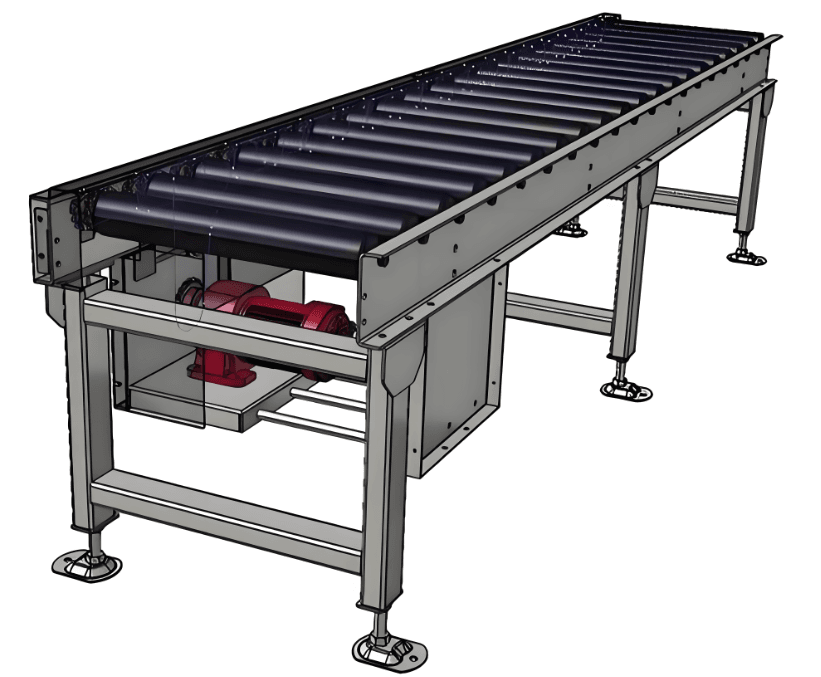

A roller conveyor is an efficient material handling system designed to facilitate the easy movement of goods. Composed of a sequence of cylindrical rollers set within a frame, the conveyor uses gravity or motor power to propel items along the rollers’ smooth surfaces.

Descriptio

Chain Driven Live Roller Conveyor Manufacturer

Chain-engaged dynamic roller conveyor is a material handling system featuring chain-linked rollers that propel items forward. Designed to manage heavy loads such as steel sheets, beams, drums, tires, and palletized products, these conveyors are ideal for substantial goods resting flat or on pallets. Frequently utilized in parcel transportation, product accumulation, and the movement of automotive tires, these conveyors are adept at streamlining various material handling tasks.

Besides, adaptable to specific operational needs, we can customize chain-driven dynamic roller conveyors with elements like curves, turntables, zones for accumulation. And straight runs to create a tailored conveyor system. Market trends for these conveyors are shaped by factors. Such as evolving customer requirements, technological advancements, ecological standards, and the competitive landscape.

The market expansion for chain-driven roller conveyors is spurred by an increased need for dependable, efficient material handling systems across multiple sectors. Including warehousing, food processing, automotive manufacturing, electronics, and mining. Besides, the shift towards automated and digitized manufacturing and logistical workflows further amplifies the demand for these conveyors.

Moreover, Manufacturers are continuously innovating to stay abreast of these trends, developing new models that excel in functionality, aesthetics, and eco-friendliness. Innovations within this space include the creation of new chain compositions decreasing friction and wear. And roller materials that heighten corrosion resistance and longevity, drive mechanisms that elevate power utilization and efficiency, and versatile, modular designs that offer flexible system configurations.

Conveyor Data

Features

The roller conveyor system primarily consists of rollers, support frames, power units, passive components. Besides, transmission chains, among other elements, and is characterized by:

1. Robust Transport Capability: The system’s conveyance strength is determined by the quantity and dimensions of its rollers, which can be tailored to meet the demands of extensive and high-efficiency logistical operations.

2. Extended Transport Reach: To accommodate the necessity for lengthy, uninterrupted transport, the roller conveyor can be assembled from numerous sections as required.

3. Versatile Compatibility: With its ability to handle a diverse array of item shapes and sizes, such as packets, drums, and various packaged goods, the roller conveyor demonstrates significant adaptability.

4. Consistent Performance: Mechanical propulsion ensures that the roller conveyor operates smoothly and reliably while also keeping operational noise to a minimum.

5. Ease of Upkeep: The straightforward nature of the roller conveyor’s construction makes maintenance tasks simple; routine upkeep involves basic cleaning and lubrication to keep the conveyor functioning efficiently.

Structures

Let’s talk about the main parts in a roller conveyor system:

Rollers: As we know, these are the heart of the roller conveyor. Imagine them as the wheels that keep the system moving. Their materials are usually strong stuff like seamless steel or aluminum pipes. To make sure they last a long time, their surface has a special wear-resistant coating.

Frame: This is what holds everything together. Then think of it as the backbone of the conveyor. Depending on what the conveyor needs to handle, we can make the frame in different ways, like welding it together or casting it.

Driving Device: This is what gets the conveyor going. It’s like the engine of a car. It includes things like motors that provide power, reducers that help control the speed. And transmission shafts that transfer the power to the rollers.

Driven Device: This part works hand in hand with the transmission chain. It’s there to make sure everything moves smoothly and in the right direction, kind of like a guide.

Transmission Chain: This links everything together. It’s like the train that connects the driving device (the engine) with the driven device (the wheels). That makes sure the whole system works like a well-oiled machine.” This version aims to make the text sound more natural and relatable. As if a human being is explaining the components in a casual conversation.

How to use a roller conveyor

When using a roller conveyor, follow these steps:

- Select the appropriate roller conveyor model and specifications according to actual needs. Then layout the equipment according to the on-site environment.

- Check whether the various parts of the equipment are intact. If there is damage or wear, replace them in time.

- Next connect the power supply and air source according to the instructions, and debug the various parameters of the equipment.

- Then place the items to be transported on the conveyor belt. And pay attention to the direction and center of gravity of the items should be consistent with the conveyor belt.

- Next start the equipment and observe whether the conveyor belt runs smoothly. If there is any abnormality, stop the machine immediately for inspection.

- During the operation of the equipment, the operator should keep a safe distance. And avoid contact with the moving parts of the equipment with hands or body.

- When the items arrive at the destination, stop the machine and remove the items.

- Regularly maintain the equipment to keep it clean and lubricated.

In conclusione

All in all, the roller conveyor system is primarily using rollers, bearings, and driving mechanisms. The movement of materials occurs as they roll over the roller surfaces. Therefore, rollers are the pivotal elements of the conveyor, typically crafted from stainless steel or aluminum with considerable surface areas.

So that can boost friction between the roller and the conveyed items. Then the rotation of these rollers is what propels the objects, facilitating material movement.

On the other hand, we assemble the chain conveyor with chains, support plates, cycloidal pinwheels, and motors, among other components. Materials are carried on these support plates, moving along with the system’s flow.

So the chains act as connectors, linking the rollers to the motor and enabling the rollers to spin. Chain conveyors function by propelling materials via the cyclic movement of the chain, initiating and maintaining the forward motion of the conveyed items.