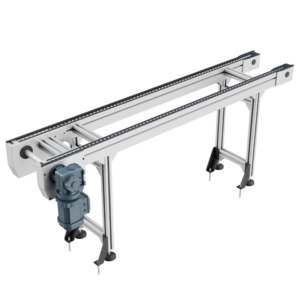

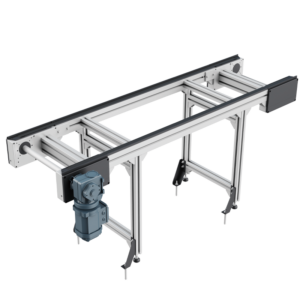

This type of conveyor harnesses the power of a timing belt, also known as a cogged or synchronous belt, characterized by its toothed surface. These teeth interact seamlessly with matching grooves in the conveyor’s pulley system, ensuring a non-slip grip that maintains exact positioning of items throughout the transport process.

Descriptio

China Timing Belt Conveyor

Timing belt conveyors stand as an efficient mechanical apparatus designed for item transportation. Meanwhile, this timing belt conveyors’ system moves items using a synchronous (or transmission) belt, incorporating a collection of gears and belts. And it’s versatile enough to handle various items, from boxes and bags to individual parts.

Key Features of Timing Belt Conveyors:

Precision in Movement: Leveraging a synchronous belt for movement, this timing belt conveyor type promises precise item placement, maintaining stability and exact positioning throughout the transfer process. –

Enhanced Efficiency: Capable of moving items swiftly, so timing belt conveyors boost production rates.

Versatile Applications: Tailorable to specific production requirements, so these timing belt conveyors are a fit for numerous industrial applications, ensuring seamless integration into different production environments.

Simplified Maintenance: Boasting a straightforward design, so these timing belt conveyors are easy to upkeep, resulting in lower maintenance expenses and hassle-free management.

Functional Roles of Timing Belt Conveyors:

Item Transportation: Designed for versatility, they can move a broad spectrum of items, including boxed goods, bagged products, and various parts.

Automated Production Enhancement: Integral to industrial production lines, these timing belt conveyors automate item movement, thereby augmenting output while trimming down labor costs.

Speed Regulation: The timing belt conveyor speed is adjustable, allowing for controlled item transmission to cater to specific production timelines.

Secured Transportation: They ensure items remain stable during movement, minimizing potential damage or loss.

Applications for Timing Belt Conveyors:

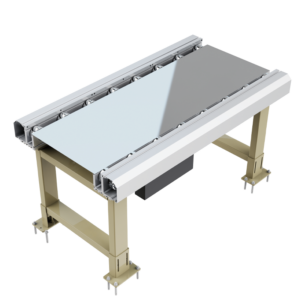

Industrial Production Lines: From car assembly to electronics manufacturing and food processing, these timing belt conveyors are fundamental for automating parts, finished goods, and other item transfers.

Logistics and Warehousing: They streamline automatic goods movement and sorting, elevating logistics efficiency.

Express Parcel Sorting: Crucial in the courier sector, these timing belt conveyors automate parcel sorting and streamline conveyor line operations.

Airport Baggage Handling: Employed in airport facilities, they facilitate automated baggage movement, ensuring efficient baggage transfer.

Installing a Timing Belt Conveyor:

1. Preparation: Identify and prepare the installation spot, ensuring adequate space and structural support. So the area should be clean and even.

2. Bracket Installation: Following manufacturer instructions, securely install the timing belt conveyor bracket, checking for stability.

3. Belt Installation: Position the synchronous belt correctly on both the drive and tension wheels, adjusting for optimal tension.

4. Power Connection: Safely connect the timing belt conveyor to the power supply, adhering to safety standards.

5. Operational Testing: Perform a test run post-installation to confirm smooth, noise-free operation. Embracing a timing belt conveyor elevates production and logistics operations significantly. For optimal results and safety, adhere strictly to the manufacturer’s installation guide during setup.

The difference between timing belt drive, V-belt drive and round belt drive

Timing belt drive transmits motion through the meshing of synchronous belt teeth and synchronous wheel teeth. This meshing transmission method makes synchronous belt drive have extremely high transmission ratio accuracy, transmission efficiency up to 98%. And smooth transmission, with buffering and vibration reduction effects.

V-belt drive relies on the friction between the belt and the pulley to achieve transmission. Its transmission ratio is relatively stable, but its accuracy is slightly inferior to that of synchronous belt drive. Besides, round belt drive is a kind of friction transmission. And its working principle is similar to that of V-belt drive.

Different transmission work:

1. Timing belt drive mainly relies on the meshing between the synchronous belt and the synchronous pulley to transmit power. And that makes its transmission ratio very accurate and there is no slippage during operation.

2. V-belt drive transmits power through the friction between the V-belt and the two sides of the V-belt pulley groove. This design enables the V-belt to transmit greater power.

3. Round belt drive is a kind of friction drive. It transmits power through the friction between the contact surface of the round belt and the round pulley. So it has good elasticity, can alleviate impact vibration, and has smooth movement and low noise.

Different use occasions

1. Timing belt drive is widely used in high-speed equipment, CNC machine tools, robotics industry, automobile industry, textile industry. And other occasions that require precise transmission due to its accurate transmission ratio and high transmission efficiency.

2. V-belt drive is suitable for occasions with short center distance and large transmission ratio due to its simple structure, stable operation and low noise. In a word, it is widely used in conveying equipment. Such as ceramic tiles, cement tiles, floor tiles, food, wooden products, printed materials, glass, etc.

3. Round belts are often used in low-speed and low-power transmission scenarios, and are widely used in various conveyors for conveying items. Such as packaging machines, printing machines, textile machines, ceramics, cement tiles, floor tiles, food, wooden products, cans, newspapers, printed materials and other conveying equipment.

Toshine Automation is a maufacturer of industrial conveyors like timing belt conveyors and other conveyors, industrial stairs and platforms, industrial enclosures and guards, aluminum workbenches. We are willing to provide any service you need. If you have any requirements, please free to contact us, thank you very much!