So experience the epitome of durability and efficiency with our pallet roller conveyor, expertly engineered to handle the most demanding workloads with ease. Transform the way you move heavy goods through your operation, ensuring smooth and reliable material handling day in and day out

Descriptio

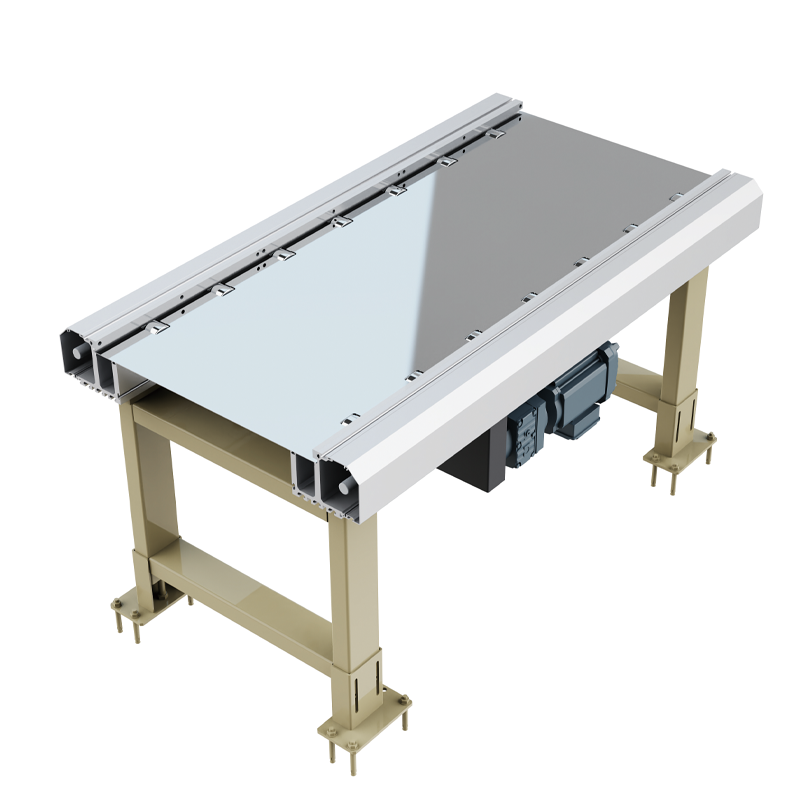

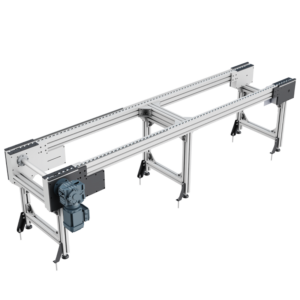

Heavy Duty Pallet Roller Conveyor

Pallet conveyors have many forms, such as roller type, chain type, roller type, plate type, lifting platform, etc. Pallet roller conveyor is just one type. In automated warehouse systems, in order to meet its capacity needs for palletized goods, cause roller type conveyors is in higher transportation efficiency, we mostly use them. The chain conveyor forms an automated pallet conveying system.

According to the needs of automatic conveying, a single type conveyor can work together to make an automated pallet conveying system. Meanwhile, this system is in specific functions. In other words, several types of conveyors can also form an automated pallet conveying system. Also it is with specific functions.

Pallet Roller Conveyor Specifications:

Model T Conveyor length L Conveying Width W Conveyor height H Conveyor Speed V Motor Position Motor Direction

TOSH-5-GS 1000~6000mm 400~1200mm As needed Max 20m/min Refer to page 12

Product Features:

- High modularity with complete supporting mechanisms for easy maintenance.

- The pallet roller conveyor conveying medium consists of rollers.

- The frame of the line is made of specialized high-strength aluminum profiles, featuring a double-supported structure for enhanced stability. Standard sections are interconnected, utilizing double-sided helical gear drive.

- Ideal for heavy-duty pallet conveying, capable of automated pallet circulation and flexible control.

- Total load less than 3000KG.

- Suitable for accumulation conveying.

Pallet Roller Conveyor Dememsional Description:

Pallet Roller Conveyor Application:

TOSH-5: Mainly in scenarios with heavy loads, featuring a robust structure capable of withstanding significant impact loads. Often utilized in automatic assembly production lines for automotive engines and transmissions.

How Automated Conveyors Work?

1. Belt conveyor

The belt conveyor has mainly two endpoint rollers and a closed conveyor belt tightly sleeved on them. The roller that drives the conveyor belt to rotate is the driving roller (transmission roller); the other roller that only changes the direction of movement of the conveyor belt is the redirecting roller.

An electric motor through a reducer drive the driving drum. And the friction drags the conveyor belt between the driving drum and the conveyor belt. We install the driving roller generally at the discharge end to increase traction and facilitate dragging.

Materials are fed from the feed end and landed on the rotating conveyor belt. Then it transportes to the discharge end by friction of the conveyor belt for discharge.

Scope of application: mainly for horizontal transportation or inclined transportation. It is very convenient to use. As we see, we use it in various modern industrial enterprises.

According to the requirements of the conveying process, a single unit can transport it. Or multiple units make it or other conveying equipment combine with it to form a horizontal or inclined conveying system to meet the needs of different layouts of operating lines.

2. Accumulation Type Suspension Conveyor

The accumulation-type suspended conveyor is a kind of transportation equipment adapted to high productivity and flexible production systems. It not only plays a transportation role, but also runs through the entire production line. And also integrate sophisticated process operations, storage and transportation functions.

With the rapid development of modern logistics transportation technology, we use accumulation conveyors widely in all walks of life. Especially in the automobile manufacturing industry, four-door assembly lines, engine assembly lines, vehicle assembly lines, etc.

The working principle of the conveyor is to realize the transportation or stop accumulation of vehicles on the spreader through the engagement and disengagement of the trolley group and the conveyor chain pusher. According to process requirements, there are two parts, fast chain and slow chain.

Fast chain is mainly for vehicle transportation or accumulation. Therefore, the slow chain is mainly for vehicle assembly. And its aim is to adjust the rhythm of the production line according to the production process station and chain speed. Hoc tempore, the traction chain can only carry the vehicle on the spreader away.

3. Scraper Conveyor

The scraper conveyor is a continuous conveyor with a flexible traction mechanism. And it is for conveying coal in coal mining and tunnels. The traction component is a scraper chain, and the load-bearing device is a middle trough.

There are many types of scraper conveyors. And some components are different. But their main structure and basic components are the same. It consists of four parts: head, body, tail and auxiliary equipment.

The slotted body is used to support coal, gangue or materials. And the scraper is fixed on the chain as a traction component. When starting the head drive component, it lets the sprocket on the head shaft rotate. So that will lead the scraper chain to circle. And also move the material along the trough until it is unloaded on the head.

So the scraper chain scraper conveyor performs a closed cycle around the sprocket to finish material conveying.

4. Continuous Bucket Conveyor

Its working principle is that materials in the chain bucket move from the tail to the head to realize the conveying of materials. And connect to the moving plate chain, drive by the motor reducer. And these movements of chains, chain buckets and materials. The components are generally in a semi-enclosed housing with legs.

That is to say, no matter whether it is horizontal or inclined transportation, there is no relative movement between the moving parts of the chain, chain bucket and material. But the whole moves along the guide rail. As you can see, the working principle is relatively simple. Of course, in addition to the above automated conveyors, there are many types. Then we won’t introduce them here.

Finally, discover the power of automation with our pallet roller conveyor systems designed to enhance your throughput. Don’t worry, cause we are here all the time. So come and get a contact. Next step, let us move forward together