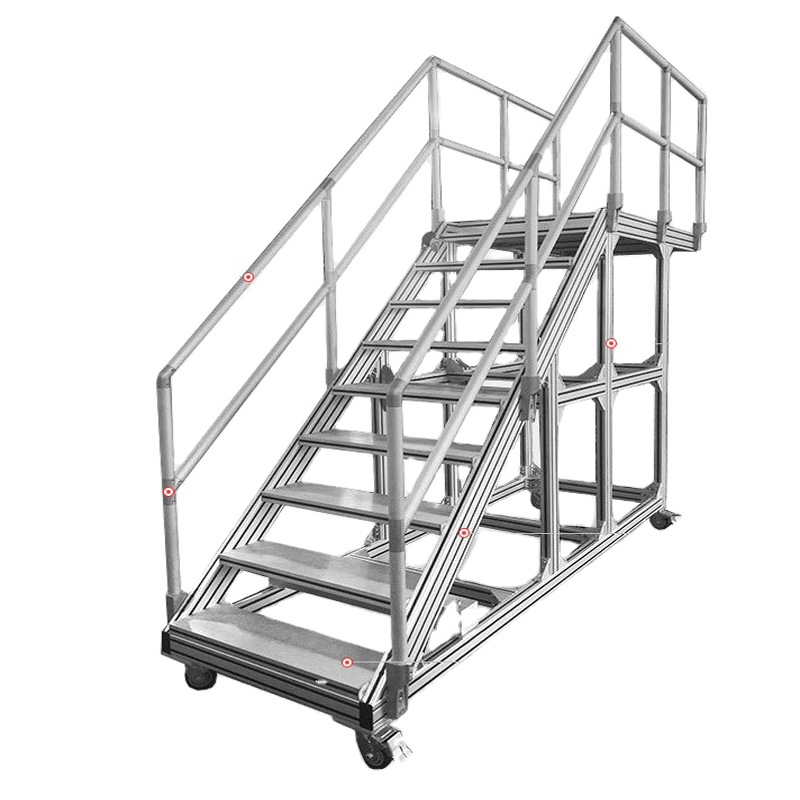

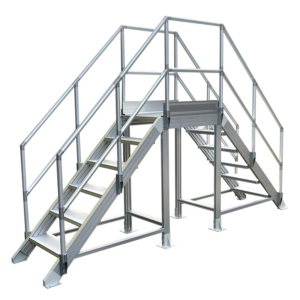

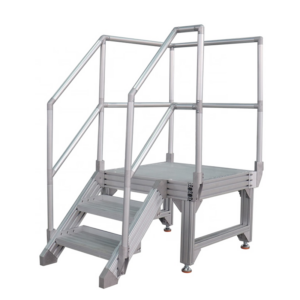

Industrial Stairs and Platforms are critical components for safe and efficient access to machinery, elevated workstations, or service areas within an industrial setting. These structures are engineered to comply with safety standards. And we can customize it to fit a variety of applications.

Descriptio

Scalae industrialis et Platforms

Industrial stairs and platforms are commonly used to connect factory equipment and personnel walkways, providing in elevated platform similar to stairs above the ground. They are fequently employed on production lines, such as machine step platforms, overhead bridge walkways, maintenance platforms, etc. Operators can quickly reach their workstations through industrial step pathways, not only increasing workers’ productivity but also ensuring their personal safety.

Constructed using aluminum profiles and accessories, we characterize industrial platforms by safety, practicality, ease of fabrication, ease of fabrication, easy installation, and convenience for fixture maintenance. Factories can design these platforms into varius shapes and functionalities based on their specific production needs.

Components of Scalae industrialis et Platforms

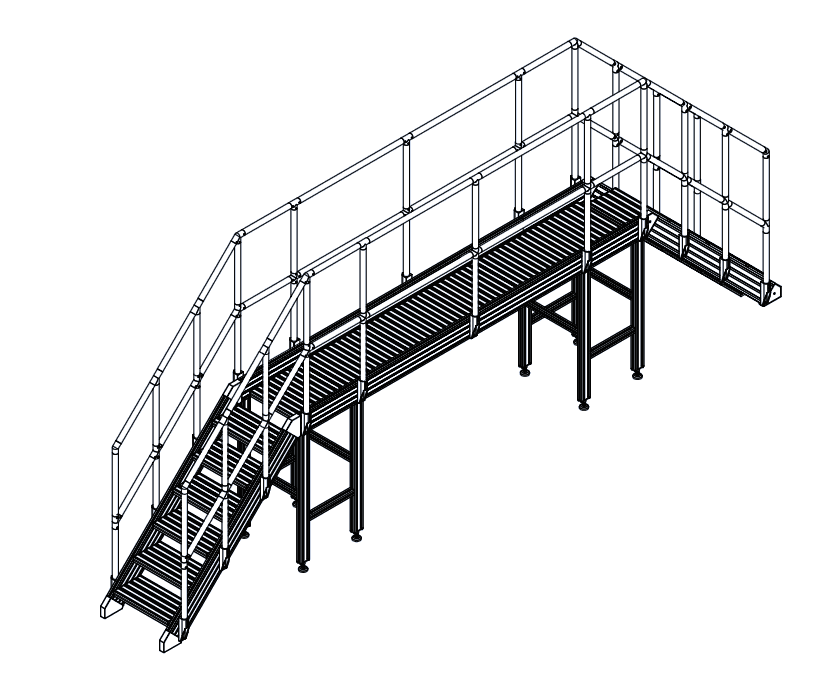

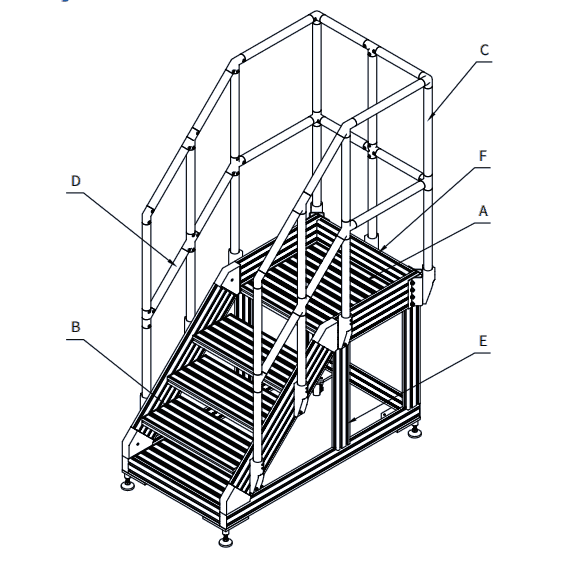

A:Platform – Elevated, stable working platform or transition platform used for high-altitude operations above the ground.

B:Stair- used for climbing, connecting the ground and the working platform.

C:Platform Railing – Surrounding the platform, a protective fence designed to ensure the safety of personnel.

D:Stair Railing – Installed on both sides of the stair, a protective fence designed to ensure the safety of personnel

E:Framework – Used to support the platform, connecting the platform, ground, and stair

F:Kick Plates – to prevent objects from falling off the platform surface.

Design Instructions for Components

Industrial Stairs and Platforms Height

The platform height should comply with ergonomic standards, i.e., the height of the working surface in an upright position should follow the standard of equipment height/body height = 6/11. Considering the actual conditions of the production line, the most comfortable operating height need be 900±150mm.

Platform Height=Working Surface Height-( 6 x Body Height/11)

Industrial Stairs and Platforms Width

The platform width is based on the scope of production requirements. Adding 200mm to the demand range decides the minimum width . The maximum width should be based on the effective space of the production line to avoid unnecessary waste of space.

Industrial Stairs and Platforms Length

The platform length is generally related to the length of production requirements. The ends should be appropriately extended to ensure the safety of operators and to reserve space for workstations, tools, and other auxiliary facilities

Industrial Stairs and Platforms Stair

The platform stair is the most crucial aspect to consider in the entire platform design. Such as the width, height, and opening positions of the stairs need to meet the requirements of ergonomics and safety in production.

The design of the stair should consider the following factors:

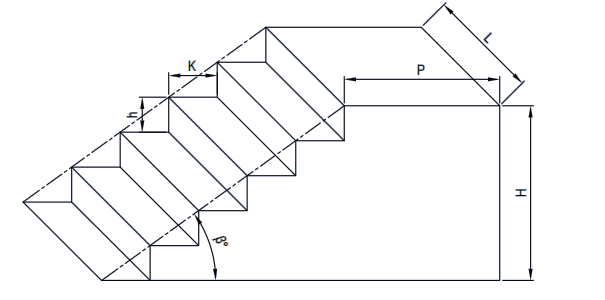

- The tread pitch K (the horizontal distance between two adjacent treads) and the vertical height h ( the vertical distance between two adjacent treads) should satisfy the following equation: 600 ≤ K + 2h ≤ 660. Where h ≤ 250mm and K ≥ 100mm. Based on practical experience and ergonomic theory, the tread pitch in on-site cascade design be set to K = 230±30mm and the vertical height be set to h = 200±30mm

- The slope β should be determined based on factors such as on-site platform height and cascade width. In general, β is between 30° and 38°, with 38° being the angle most in line with the natural gait of the human body. Depending on different situations, we can also design it to standard angles such as 45°, 60°, or other non-standard angles.

- The platform height H should not exceed 3m, in special cases, this height should not exceed 4m. Otherwise, before reaching another platform, we need to add an additional step. The length of the step should be at least 800mm and greater or equal to the width of the stairs.

- The connection position between the stairs and the platform should between adjacent workstations. And we can adjust it based on the distribution of workstations on-site

h: Stair height K: Tread pitch H: Platform height P: Platform length L: Platform width θ: Stair angle

Scalae industrialis et Platforms Railings

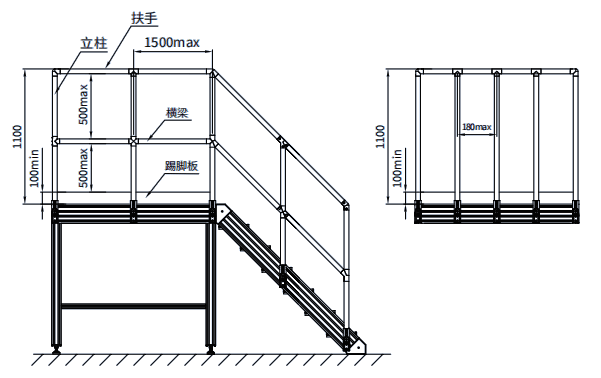

To prevent operators from accidentally falling or entering dangerous areas, it is necessary to install guardrails in the platform area. The general platform guardrail installed in the platform area. The general platform guardrail installed in the platform area you can see in Figure2.

The principle of adding guardrails in the platform area is:

- When the platform height exceeds 500mm, we should install guardrails.

- If the gap between the operating platform and the machine frame or wall is less than 200mm. And the protective effect of the frame is equivalent to a railing, it is not necessary to install a railing. tamen, when the gap between the operating platform and the adjacent frame is greater than 300mm, we should install a kick plate.

- Railings should include at least one middle horizontal beam or some other equivalent protection. The free space between rails and beams, as well as between beams and kick plates, should not exceed 500mm. In special cases where the railing height is higher, we may add an additional middle horizontal beam.

- When using strut instead of beams, the maximum horizontal spacing between each strut should be 180mm.

- When using strut instead of beams, the maximum horizontal spacing between each column should be 180mm.

- We generally set the guardrail height at 1100mm.

- The specific placement of additional rails should take into account the actual conditions on the site.

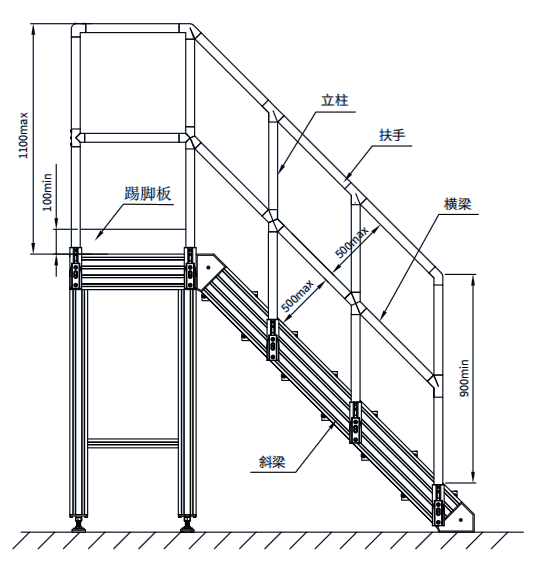

If the platform steps are too high, too narrow, or have other special requirements, we should add at the steps to ensure production safety. The general step railing you can see in Figure 3.

The design requirements for step railings are:

- When the ascending height of the step is more than 500 mm, and there is a lateral spacing greater than 200 mm on the outside of the inclined beam. So additional guardrails should be attached to its side. The vertical height of the handrail should be at least 900 mm.

- To ensure a secure grip, the handrail should have a circular cross-section with a diameter between 25 and 50 mm. Or an equivalent cross-section that is easy to grip by hand.

- The railing should include at least one horizontal beam or an equivalent device. The clear spacing between handrails and beams, as well as between beams and inclined beams, should not exceed 500mm

Industrial Stairs and Platforms Kick Plates

To prevent objects from falling off the platform surface and creating hazards, the minimum height of the kick plate should be 100mm.