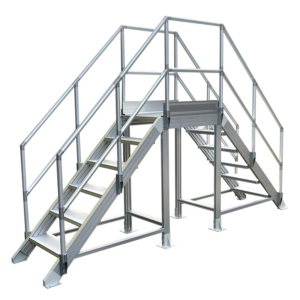

Whether it’s for manufacturing facilities, warehouses, or any other industrial application that requires safe and efficient access, our aluminum Profile ladders deliver unparalleled performance and reliability. Experience the difference of our precision-engineered solutions and elevate your access capabilities to new heights.

Descriptio

Portable Stairs with Platforms Suppliers

Aluminum Profile Ladders Advantages:

Aluminum profile ladders have many benefits, including lightness, corrosion resistance, high safety, wide application, and easy installation and maintenance.

Lightweight: Aluminum profile ladders, we use high-strength aluminum alloy profiles. They are lighter and easier to carry and transport than traditional ladders such as steel ladders. This is especially important for work scenarios where we need move ladders frequently.

Corrosion resistance: Aluminum profile ladders have excellent corrosion resistance. And we can use in harsh environments such as moisture, acid and alkali without rusting, extending the service life of the ladder.

High safety: Aluminum alloy ladders use advanced square tube extrusion riveting technology, with a stable structure and not easy to deform. At the same time, people also equip aluminum alloy ladders with strong anti-slip ladder feet. So that can effectively prevent the ladder from sliding during use and improve the safety of use.

Wide application: Aluminum alloy ladders are suitable for various terrains and usage scenarios, such as industrial sites, daily home use, etc. Its lightness and corrosion resistance enable aluminum alloy ladders to perform well in a variety of environments.

Other Advantages of Aluminum Profile Ladders

Easy to install and maintain: Aluminum alloy ladders adopt a simple and quick installation principle, and are easy to disassemble and assemble. At the same time, aluminum alloy materials are easy to clean and maintain. So it can keep the ladder looking new.

Autem, the advantages of aluminum profile step ladders include:

Various specifications: People can select different aluminum profiles for assembly according to the span and load-bearing capacity of the stair treads.

No specification restrictions: People can customize it according to actual needs to meet various specific needs.

Flexible installation: Workers use industrial aluminum profile accessories for installation and locking, without welding. So it is easy to install and disassemble, and is sturdy and beautiful.

Mobility: People can install casters, and will move flexibly, unlike traditional stair treads that we cannot move.

Durability: The structure is sturdy, anti-corrosion, wear-resistant and rust-proof, and no maintenance. It is suitable for multiple production workshops and large-scale mechanical equipment as an inspection platform

How Do you Assemble It?

Workers use the aluminum profile ladders to cross the line. We mainly use it to cross the height of the human body, and is convenient for operation and taking objects at high places. It is suitable for occasions where obstacles need to be crossed in workshop passages or assembly lines.

And can also use as a mobile platform for both sides. In real life, the specifications of aluminum profile ladders are relatively large, and many people worry about assembly problems.

1. The customized aluminum profile ladders do not need welding. And we can complete the assembly work directly with the corresponding accessories. It is simple and convenient, with a short construction period, which is convenient for later transformation work. This is also the reason why modern factories like to use industrial aluminum profiles.

We divide the specific assembly process of the aluminum profile ladders into 3 steps. Before assembly, during assembly and after assembly, and we need carry out each assembly process according to requirements.

2. Before assembling the aluminum profile ladders, find an open space to ensure that the space is large enough and does not affect the normal construction work.

It is also necessary to lay a layer of cotton cloth on the open space, put the required aluminum profiles, accessories, plates, etc. on the cotton cloth, and familiarize yourself with the specifications of various profiles, the assembly methods of accessories, etc. according to the drawings, so as to have a clear idea, which can reduce the occurrence of errors during the installation process.

Next You Need to Do

3. The entire installation process requires technicians to assemble. So as to ensure the accuracy of the assembly and the delivery time. Autem, we must follow the assembly sequence from bottom to top during the assembly process。

And workers must use professional assembly tools (hexagonal wrenches, rubber hammers, etc.) to ensure the accuracy of the installation, thereby reducing the situation of bolts and nuts being screwed. The installation of the wire ladder generally requires 3-6 people to assemble.

4. After we complete the installation, check whether the wire ladder is shaking? Are there any bolts and nuts that are not tightened? Is there any unreasonable situation in the structure, etc. If it appears, the technicians can correct it on the spot. If require rework, the technicians can return to the factory for rework until the customer is satisfied.

So this is also the reason why many wire ladder customers look for aluminum profile manufacturers. After-sales service is assured, there will be professional technicians to provide design solutions, professional experience, and reliable quality.