Descriptio

Pallet Handling Conveyors: Revolutionizing Internal Goods Transport

What Is Toshine Pallet Conveyor Handling System?

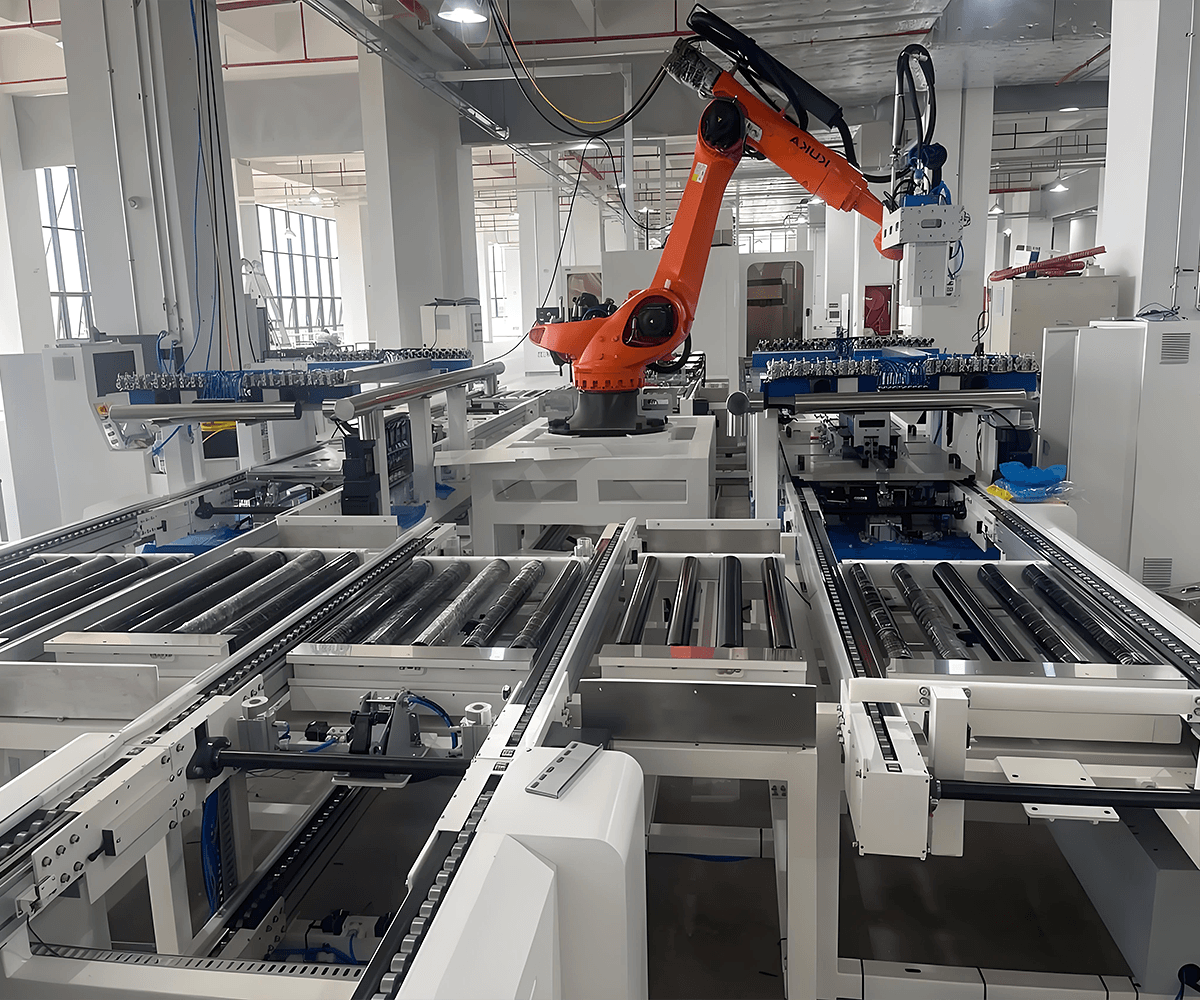

Pallet conveyor systems have become essential in modern warehousing and manufacturing. Besides, people can design them to simplify and automate the movement of palletized loads. These systems consist of motorized components like chain or roller beds that enable a controlled and continuous transfer of pallets.

| Item | Descriptio |

|---|---|

| Product Name | Toshine Automated Roller Conveyor For Cartons |

| Material | Stainless Steel / Carbon Steel / Galvanized Steel / Plastic |

| Roller Diameter | 38, 50.6, 60, 76, 80, 89…..As your application |

| Processing | Injection molding and machining |

| Structure | Height/Speed adjustable |

| Maximum Load | 1000 kg /m |

| Application | Food & Beverage, Packing Industry, Pharmaceutical etc. |

Advantages of Pallet Conveyor Systems

- Full Automation

– Pallet conveyor systems operate automatically. Once set up, they can continuously transport pallets without the need for constant human intervention. This frees up manpower for other value-added activities. - Increased Productivity

– Loading and unloading pallets is much faster. The time between different points in a large facility is significantly reduced. Exempli gratia, a pallet can quickly travel from the receiving area to the storage section or the production line. This constant product flow boosts overall productivity. - Great Versatility

– Simple circuits can move pallets in a straight line for basic transport. Besides, more complex ones can accumulate pallets in a specific area, turn them at corners, or even elevate them to different levels. This flexibility allows the system to adapt to diverse logistical requirements. - Safety

– Manual pallet handling and heavy forklift traffic pose risks. So pallet conveyor systems reduce these risks. Workers have less direct contact with heavy pallets, and there is less chance of forklift collisions or accidents related to manual lifting and moving. - Bottleneck Prevention

– Powerful simulation tools are used to optimize conveyor lines and flows. By carefully planning the layout and operation of the conveyors, bottlenecks where pallets might pile up or slow down the process, we can avoid. This ensures a smooth and uninterrupted movement of goods. - Flexibility and Scalability

– If a business expands or changes its operations, the pallet conveyor system can be modified. And we can add new conveyor sections, or relocate existing ones. This adaptability makes it a long-term solution for evolving logistical needs. - Quick Installation

– A plug-and-play system connects pallet conveyors often. This means we can install them rapidly and put into operation without significant delays. This is especially beneficial when a business needs to quickly upgrade or install a new transport solution.

Conclusion

Pallet conveyor systems offer numerous benefits that enhance the efficiency and safety of internal goods transport. So their ability to automate, increase productivity, provide versatility, and adapt to changing business needs makes them a valuable asset in any warehouse or manufacturing environment.

As technology continues to advance, these systems are likely to become even more sophisticated and integral to the success of businesses involved in logistics and production.

Pallet Conveyor System Applications

Pallet handling conveyors are to shift pallets and other heavy things. They use belts, chains, skatewheels, or rollers to do this. Thus, these conveyors can move big and heavy products in a careful and safe way. So this helps industries that deal with such large loads to have a better system throughput.

Toshine offers many choices for pallet handling. Thus, these can work for any weight of pallets, different pallet setups, or various environmental conditions.