6 Common Types of Pallet Lifts

Rod Cylinder Lift

Rod cylinder drives lifting to ensure structural stability.

Veelgebruikt zijn standaardcilinders.

Toepasbaar op dubbellaagse transportlijnen, en de heflast kan over het algemeen 200 kg bereiken.

(Combinatie van een servo-snelheidsregelklep en een vijfweg centrale afvoerklep met drie standen)

Rodless Cylinder Lift

Rodless cylinder drives lifting, compact structure, and space saving.

Applicable to small spaces and small loads (generally less than 60KG).

Commonly used in double-layer conveyor lines.

(Combinatie van een servo-snelheidsregelklep en een vijfweg centrale afvoerklep met drie standen)

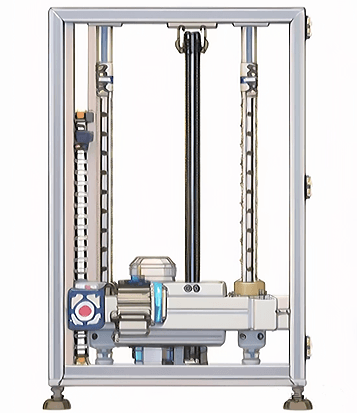

Cylinder Chain Lift

Cylinder drives chain lifting, and the lifting stroke is twice the cylinder stroke.

Compared with rod cylinder direct drive lifting, it can provide a larger lifting range.

With the same stroke, the external frame size is lower, which reduces the space occupied by the machine, improves flexibility and layout efficiency, and generally lifts 200KG load, which is suitable for double-layer conveyor lines.

(Combination of pilot-operated speed regulating valve and three-position five-way center drain valve)

Motor Chain Lift

Motor driven lifting,

Stable structure, high equipment operation safety, lifting load can generally reach 200KG,

Applicable to double-layer or multi-layer conveyor lines. (The motor must be brake type)

Motor Synchronous Belt Lift

Motor driven synchronous belt lifting, fast lifting speed, laag geluidsniveau,

Lifting load is not large (generally less than 60KG).

Applicable to double-layer or multi-layer conveyor lines, fast production rhythm,

Occasions with small load. (The motor must be brake type)

Screw Lift

Servo motor drives screw lifting, High positioning accuracy, fast lifting speed, lifting load can reach 200KG. Applicable to double-layer or multi-layer conveyor lines, fast production rhythm, high positioning accuracy. (The motor must be brake type)

Automatic pallet lift is a device used to automatically lift pallet goods between different heights. It usually consists of motor, transmission system, lifting mechanism, control system and other parts. Through precise control and mechanical transmission, pallets and goods can be lifted or lowered to the designated position efficiently and stably.

This equipment is widely used in logistics warehousing, factory workshops and other places, which can greatly improve the efficiency of cargo handling and storage, reduce manual labor intensity, and reduce the error rate during operation.

When designing and using, it is necessary to consider multiple factors such as load capacity, lifting speed, accuracy requirements, safety protection, enz. to ensure that it can meet the specific work scene requirements.

About Toshine Automation

We focus on providing high-quality, comprehensive automated and modular conveying system solutions for new energy, auto parts, 3C electronics, photostatic, logistics and other automated industrial fields, meeting the industry’s requirements for precision, snelheid, betrouwbaarheid, stability and other aspects needs.

Main products: timing belt conveyor, ribbed belt conveyor, double speed chain conveyor, gravity roller conveyor, belt conveyor, roller conveyor, mesh belt conveyor, flexible chain conveyor, pallet conveyor, as well as supporting mechanisms like lifting and transverse shifting, turnables, elevators for conveyor lines, and protective barriers system, cross-line ladders, step platforms, aluminium werkbankes and other ancillary facilities.