7 Opkomende trends die industriële automatisering vormgeven in 2025

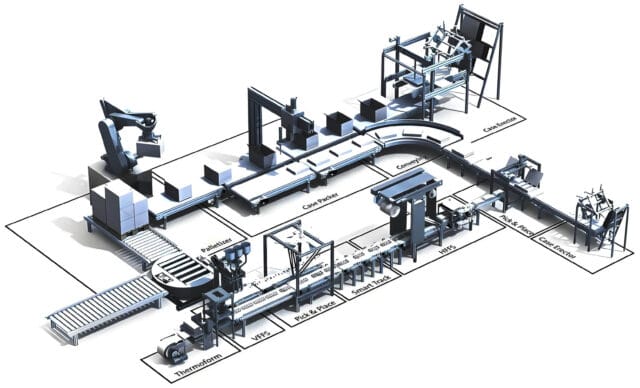

De industriële automatiseringssector ondergaat zijn meest transformerende fase in decennia. Naarmate fabrikanten worden geconfronteerd met druk voor duurzame activiteiten, Flexibele productielijnen, en veiligheidsverbeteringen van het personeelsbestand, Innovatieve oplossingen voor materiaalbehandeling worden cruciale onderscheiders. Laten we de belangrijkste trends verkennen die transportsysteem innovaties aansturen:

1. Sustainable Manufacturing Demands

Modern conveyor systems now play a dual role in production efficiency and environmental compliance. Your pallet conveyors and roller conveyors can now be equipped with:

- Energy-recovery systems in belt conveyors

- Low-friction roller designs reducing power consumption by up to 30%

- Recyclable chain components in chain conveyor systems

2. AI-Enhanced Predictive Maintenance

The integration of smart sensors in our conveyor solutions enables:

- Real-time monitoring of chain tension in chain conveyors

- Vibration analysis for roller conveyor bearings

- Predictive replacement alerts for belt conveyor wear parts

3. Collaborative Robotics Integration

Modern safety guard fencing solutions now feature:

- Modular designs compatible with mobile robot workcells

- Smart safety curtains that adapt to collaborative robot speeds

- Integrated access platforms (industrial step platforms) for hybrid human-robot workspaces

4. Digital Twin Implementation

Our conveyor system designs now support:

- Virtual commissioning of complete pallet conveyor networks

- Physics-based simulations for roller conveyor load testing

- Wear pattern predictions for chain conveyor components

5. Supply Chain Resilience Strategies

Modular conveyor components enable:

- Rapid reconfiguration of roller conveyor layouts

- Scalable extension of belt conveyor lines

- Standardized safety guard fencing systems for fast facility expansions

6. Workforce Safety Innovations

Next-gen protective solutions include:

- Anti-microbial coatings on industrial step platforms

- Smart lighting integrated into pallet conveyor pathways

- Ergonomic access points in roller conveyor maintenance zones

7. Upskilling Through Automation

Our systems support workforce development with:

- AR-assisted maintenance guides for chain conveyor repairs

- Virtual training modules for belt conveyor troubleshooting

- IoT-enabled diagnostic tools for roller conveyor technicians

Why Modern Transportband Systems Matter More Than Ever

As production lines face demands for:

- 35% faster changeovers (achievable through modular roller conveyors)

- 50% reduction in downtime (enabled by smart chain conveyor monitoring)

- 100% safety compliance (ensured by next-gen guard fencing systems)