Aluminum extrusion belt conveyors are very popular in factories. We can use 30 or 40 T slot for its structure. So it is very easy and convenient to assemble. Light weight design, high strength, corrosion resistance and modular design are its structural features.

Beschrijving

Transportband van aluminium profiel

Aluminum profile belt conveyors, we mainly use for material transportation in factories. They can achieve long-term, continuous operation and can meet the production needs for smart factories. As we know, belt conveyors can be seen in major factory workshops.

Industrial aluminum profiles were once named the special materials for belt conveyors due to their own advantages (environmental protection, recyclability, no need for welding, no need for painting, low post-maintenance costs, enz.

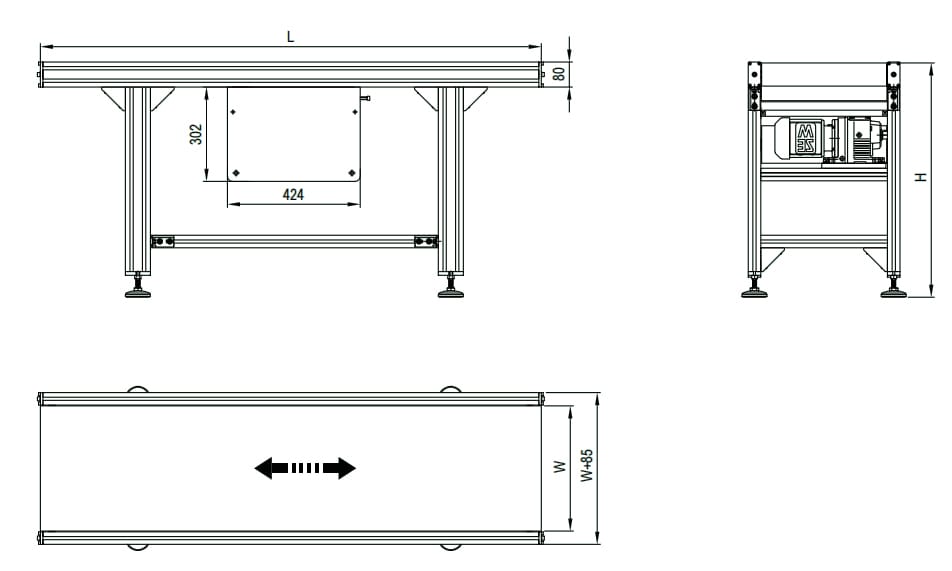

Specifications:

Model conveyor Length L Conveyor Width W Conveyor Height H Conveyor Speed V Speed Control

TOSH-BE-40M 0.6~6m 300~1000mm As needed Max 40m/min Fixed F/Variable V

Producteigenschappen:

- 40 series aluminum profiles and components, allowing easy integration with other complementary mechanisms like guardrails, sensors, enz.

- Center-driven unit enabling bidirectional conveying with a maximum load capacity of 120KG.

- Simple and reliable structure with low maintenance;

- Recommended operational speed is below 20m/min; exceeding this limit may reduce the product’s longevity.

- Guardrails are available in fixed and adjustable widths, selectable based on specific requirements.

Dimensionale beschrijving:

Design Principles of Aluminium extrusie transportband

Conveyors play an important role in the production process, efficiently moving materials from one location to another. With the rapid development of the manufacturing industry, the demand for conveyors continues to increase, and the performance requirements for conveyors are also getting higher and higher. As a material with excellent properties, we use aluminum profiles widely in conveyor design.

Aluminum profile conveyors use aluminum profiles as the main structural material. So it can realize material transmission by connecting aluminum profiles into conveyor belts or conveyor chains. Aluminum profiles have the advantages of lightweight, high strength, corrosion resistance, enz., and can meet various needs of conveyors.

Tegelijkertijd, the aluminum profile conveyor adopts a modular design and we can customize it according to actual needs, giving it high flexibility.

Structural Features of Aluminum Profile Conveyor

- Lightweight design: The low density and light weight of aluminum profiles can reduce the total weight of the conveyor, thereby reducing energy consumption and maintenance costs.

- High strength: Aluminum profiles have high tensile strength and compressive strength, and can withstand large material pressure and friction, ensuring the stable operation of the conveyor.

- Corrosion resistance: Aluminum profiles have good corrosion resistance and can maintain stable performance in harsh environments and extend the service life of the conveyor.

- Modulair ontwerp: The aluminum profile conveyor adopts a modular design and we can customize that according to actual needs for easy installation and maintenance.

Application of Aluminum Profile Conveyors

- Manufacturing industry: Aluminum profile belt conveyors are widely used in manufacturing industries, such as automobile manufacturing, electronics manufacturing, food processing, enz.

- Logistics industry: Aluminum profile belt conveyors can be used in warehouses, distribution centers and other places in the logistics industry to achieve rapid transmission of materials.

- Agricultural field: In the agricultural field, aluminum profile belt conveyors can be used to transport grain, feed and other materials.

- Other fields: In addition to the above fields, aluminum profile belt conveyors can also be used in construction, chemical industry, medical and other industries.

Future Trends

With the continuous development of science and technology, the design of aluminum profile conveyors will become more intelligent and automated. In the future, aluminum profile conveyors will adopt more advanced transmission systems and control systems. Because it can achieve more precise material transmission and higher production efficiency.

Tegelijkertijd, with the improvement of environmental awareness, aluminium profielen, as an environmentally friendly material, we use it widely in conveyor design. In aanvulling, with the development of Internet of Things technology, aluminum profile conveyors will realize functions. Such as remote monitoring and fault diagnosis, improving the reliability and safety of the equipment.

Machine Assembly Line Belt conveyor

The structure of the belt conveyor is relatively simple, the maintenance is relatively convenient. As we know, it can transport a wide variety of materials. Because rubber conveyor belts have high corrosion resistance, maintenance costs are relatively low when conveying highly corrosive or highly abrasive materials. The belt conveyor can also transport alkaline materials and hot materials at a certain temperature, as well as complete items.

The conveying capacity of the belt conveyor is wide. The conveying capacity of the belt conveyor can meet any required conveying tasks. There are light belt conveyors to complete the conveying tasks with small conveying volumes. So large belt conveyors to achieve thousands of tons per hour or even Transportation tasks of tens of thousands of tons.

The conveying line of the belt conveyor has strong adaptability. The belt conveyor can adapt to terrain with a slope of 30% naar 35%. While for truck transportation, it can only adapt to the slope of the original natural terrain of 6% naar 8%.

Conveyor lines can adapt to the terrain, bending in space and horizontal planes to reduce infrastructure investment. Bovendien, it can avoid interference from railways, roads, rivers, and mountains in factories or other congested areas. The transportation route of the belt conveyor is very flexible. Daarnaast, the length of the route can be extended as needed.

More about Lopende band

Daarnaast, the belt conveyor can flexibly load and unload materials. The belt conveyor can flexibly receive materials from one or more points according to the requirements of the process flow. And can also discharge materials to multiple points or several sections.

It has high safety. The belt conveyor has high safety, requires few production personnel. And has fewer chances of accidents compared with other modes of transportation. There will be no accidents caused by large pieces of material falling down. And injuring people or due to malfunctioning of large and heavy vehicles.

The labor hours and energy consumption required per ton of bulk materials transported by belt conveyor systems are generally the lowest among all tools for transporting bulk materials. Bovendien, it takes up less time for maintenance personnel. We can complete repair and replacement of smaller parts quickly on site, and the maintenance cost is low. Belt conveyors are usually in machine assembly lines and play a great role.