An aluminum extrusion roller conveyor is a streamlined material handling solution crafted from high-grade aluminum profiles, designed to transport goods across various industrial environments. Ideal for both heavy-duty and lightweight applications, this conveyor system provides a reliable and cost-effective method for streamlining workflow and improving overall productivity.

Beschrijving

Aluminium extrusie rollenbaan

The roller conveyor line refers to a machine. And it can transport a single piece of material with a large weight or withstand a large impact load. It is suitable for transporting various types of boxes, bags, pallets and other items. Bulk materials, small items or irregular items need to be on pallets or in turnover boxes for transportation.

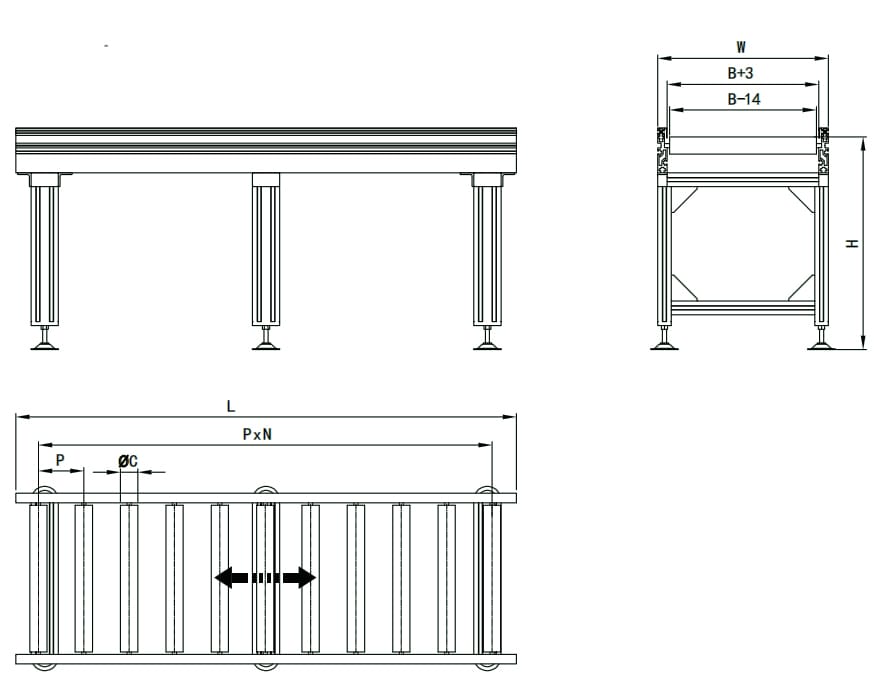

Roller Conveyor Specifications:

Model Conveyor Length L Conveyor Width W Conveyor Height H Roller Spacing P

TOSH-RL-F L≥600mm 100~1200mm As needed As needed

Producteigenschappen:

- Simple and reliable structure with low maintenance;

- Roller diameters: φ38, φ50.6, φ60, φ76, φ80, φ89… selectable based on requirements.

- Conveys via rollers made of materials such as carbon steel, stainless steel, plastic, enz. Surface options include rubber coating, selectable as needed.

- T -slot aluminum profiles frame for easy accessory attachment

- Maximum load of up to 1000kg/m, capable of withstanding significant impact loads, catering to various conveying needs.

- Suitable for accumulation conveying.

Dimensionale beschrijving:

Working Principle of Non-powered Roller Conveyor Line

The non-powered roller conveyor relies on a simple yet effective principle. And it can move materials from one point to another without the assistance of power:

- Material Positioning: Begin by placing goods at the non-powered roller conveyor’s start. These items may range from papers to fabrics of different dimensions and forms.

- Roller assembly: Central to the conveyor, rollers are arranged uniformly on a supporting frame to create the conveying surface. These cylindrical components, often crafted from metals or composite materials. Also boast a finely textured surface to enhance grip with the items they transport.

- Motion through Friction and Inclination: Once items are set upon these rollers, they begin advancing due to the traction created between their surfaces and the rollers’. A deliberate tilt applied to the setup compels the goods to glide along the rollers’ bearings, propelled by both friction and gravitational pull.

- Regulation of Movement: The conveyor’s efficiency hinges on the strategic angle of the rollers and their separation – factors that determine the rate and steadiness of item movement. Correct calibration prevents congestion and slippage, ensuring a smooth transit.

- Destination Reach: Guided by the roller’s trajectory, items eventually arrive at the conveyor’s end, where they can be collected for further processing or transferred to the next stage of operation.

Algemeen, this method capitalizes on the passive forces of friction and gravity. And it offers an economical and flexible solution for material handling across diverse applications.

Analysis of Application

Application of Non-powered Roller Line

The unpowered roller line is a conveying equipment based on the gravity of the material itself. When we use, the material only needs to be on the roller line. And the material is directly transported to the destination through the rolling of the roller.

we can widely use it in the field of warehousing and logistics. At the same time we can also use it to transport materials within the production workshop.

Advantages and Disadvantages

1. Advantages of Non-powered Roller Line

- Low cost: Compared with other conveying equipment, the cost of unpowered roller lines is low and easy to install and maintain.

- Small footprint: We can customize the unpowered roller line according to actual needs, effectively utilizing space and saving floor space.

- High transportation efficiency: The unpowered roller line uses the material’s own gravity to transport materials. It is faster and can realize batch transportation.

2. Disadvantages of Non-powered Roller Lines

- Material restrictions: Due to limitations in transportation methods, the non-powered roller line is only suitable for some materials with relatively fixed physical properties. And the types of materials that we can convey are subject to certain restrictions.

- Height restriction: Due to the effect of gravity, the unpowered roller line is only suitable for some conveying tasks with lower heights. But is not suitable for conveying tasks with higher heights or that require changing directions.

- Safety risks: During long-term operation of the unpowered drum line, safety risks. Such as blockage may occur due to excessive stacking of materials, or fire may occur due to friction of materials on the drum

How to Avoid the Shortcomings of Non-powered Roller Conveyor Lines?

In order to avoid the above problems, we could take the following improvement measures:

- When designing the unpowered roller line, we should selet the appropriate conveying method. And it is according to the properties and transportation needs of the specific materials to ensure that the materials can be transported smoothly.

- Carry out regular maintenance and upkeep on the equipment. And arrange cleaning in time to avoid blockage caused by accumulation of materials.

- In the system design, try to reduce the number of turns and vertical height of the material to avoid safety risks.

Samenvattend, as an effective material conveying equipment, the unpowered roller line has certain application advantages and scope of application. But it is also necessary to pay attention to its shortcomings and precautions during actual use to ensure its safety and stability.