Automated pallet conveyors emerge as a game-changer in the logistics and manufacturing arenas. Their versatility, efficiëntie, betrouwbaarheid, and adaptability make them an indispensable asset for enterprises.

By streamlining operations, reducing costs, and enhancing productivity, they pave the way for businesses to thrive in a competitive global market. Embracing this technology not only resolves immediate logistical challenges but also unlocks the door to a future of intelligent and sustainable growth. So it’s an investment that promises to yield long-term dividends and position companies at the forefront of innovation and success.

Beschrijving

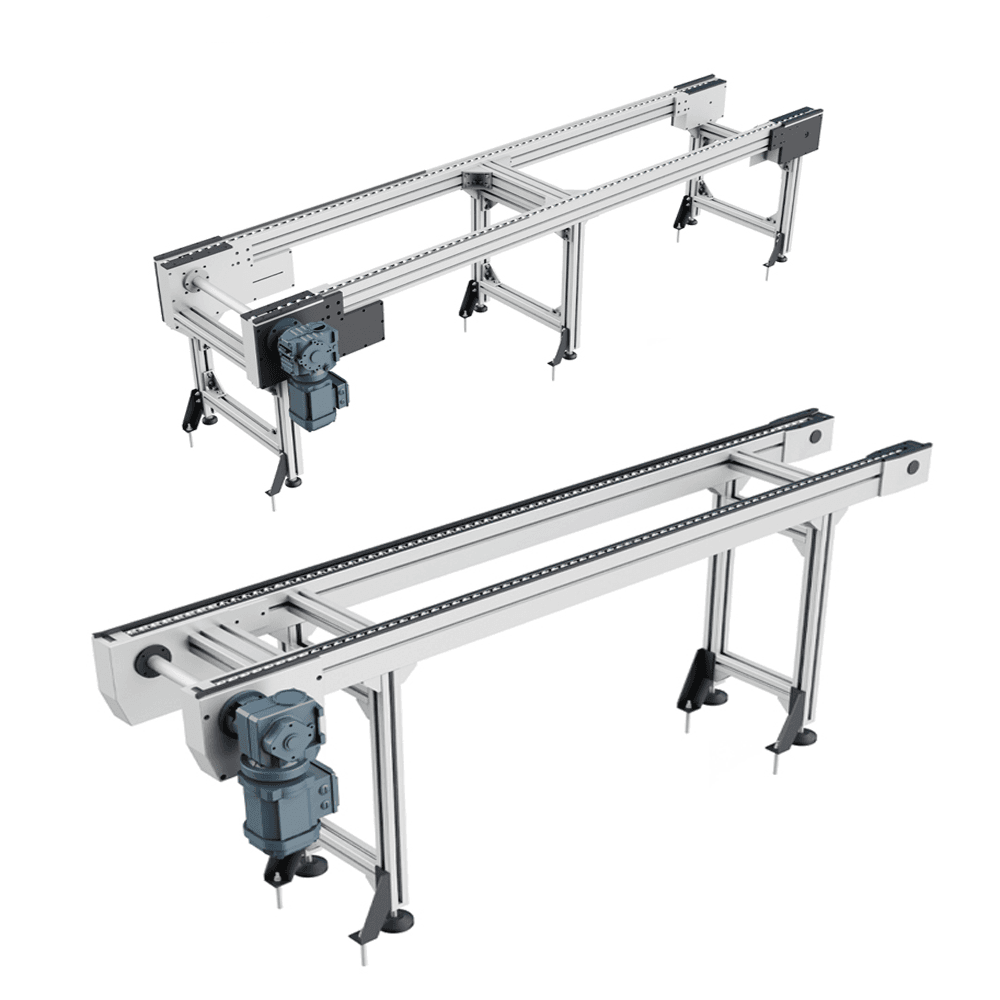

Toshine Automated Pallet Conveyors For Industry

Automated Pallet Conveyor: the Transformative Force of Modern Logistics and Manufacturing

What is an Automated Pallet Conveyor?

Automated pallet conveyors are crucial in modern logistics and manufacturing. So they automatically and continuously move palletized goods. In big e-commerce warehouses, they take pallets full of products from storage to sorting areas. Thus, they work precisely in busy warehouses or between production lines. They follow set routes and programs.

This automation cuts manual work. Because it saves labor costs and makes transport faster and more accurate. Unlike old manual or forklift methods, they can run 24/7. Daarnaast, this shortens the time to handle goods. Dus, companies can fill more orders quickly and meet customer needs.

Customer Question: Are automated pallet conveyors good with all pallet types?

Answer: They usually work well with common pallets. But for special ones, we can adjust them during setup to make sure they run smoothly.

Where Can It Be Applied?

Automated pallet conveyors are very useful in the automotive industry. Because they carry heavy parts like engines between workshops and assembly lines. At a famous car maker’s factory, these conveyors made the material supply 30% sneller. So this stopped production delays from late part deliveries.

In één woord, the conveyors are flexible. They fit different factory layouts and processes. Daarnaast, they can go straight, turn, or even go up and down slopes. So they connect well with other logistics gear like storage systems and sorters. Thus, this makes a great automated logistics line and boosts the whole system’s teamwork.

Customer Question: Can we install it if our space is small?

Answer: Yes. We can design it to fit small spaces. We can use tall or multi-level setups. This uses space well and keeps the conveyor working fine.

How Reliable and Stable Is It?

Automated pallet conveyors are reliable and stable. In a food factory that needs clean and steady equipment, these conveyors are great. They are made well and last long. Sensors and smart systems watch over them. If something goes wrong, they tell us right away. We can then fix it fast and avoid production stops. This helps the factory focus on making food and not worry about logistics problems.

Customer Question: Is the equipment hard to maintain? Do we need pros all the time?

Answer: No. Maintenance is easy. We clean and oil parts like belts often. There are guides and training for the electrical and control bits. Normal staff can do most of the upkeep after a short training. Only for tough electrical or software issues might we need experts.

What is the Cost of Installing a Conveyor Belt?

The cost to install a conveyor belt depends on several factors, including the size of the belt, the type of conveyor, and the application:

- Belt size: The size of the belt is the most important factor in pricing. The larger the belt, the more it will cost. Size is measured by length, width, and the size of the drive pulley.

- Type of conveyor: Belt incline conveyors are more expensive than typical conveyor belts. In 2021, the average price for a belt incline conveyor in the U.S. was between $4,050 and $6,710.

- Sollicitatie: The cost of a conveyor system depends on the specific application. Bijvoorbeeld, an underground conveyor system with a 30-inch wide belt moving at 450 feet per minute over 1,000 feet might cost between $275,000 and $400,000.

- Other factors: Other factors that can affect the cost include the belt type, motor size, and simplicity of manufacturing. In het algemeen, experts recommend budgeting around $1,500 per linear foot of conveyor.

In addition to the initial installation costs, there are also operational and maintenance costs to consider. The “whole life cost” of a conveyor belt includes the cost of installation, reparaties, and lost output during maintenance.

The Future of Automated Pallet Conveyors

Investing in automated pallet conveyors is smart for a company’s growth. It makes things run better, cuts costs, and makes the company look good. In our digital world, these conveyors are key for Industry 4.0. With new tech like IoT, big data, and AI, they will get even better. So they will be able to check themselves, predict problems, and schedule jobs smarter. This will bring more value to companies in the end.

If you have slow logistics and high costs, think about automated pallet conveyors. They are efficient, smart, and reliable. They will help your company do well in the tough market and reach success. Let them start a new age of logistics for you.