A slat chain conveyor is a specialized type of conveyor system. And it utilizes slats attached to a chain to transport materials and components in various industrial applications. This system is particularly popular in manufacturing environments. So it plays a crucial role in enhancing efficiency and productivity along assembly lines.

Beschrijving

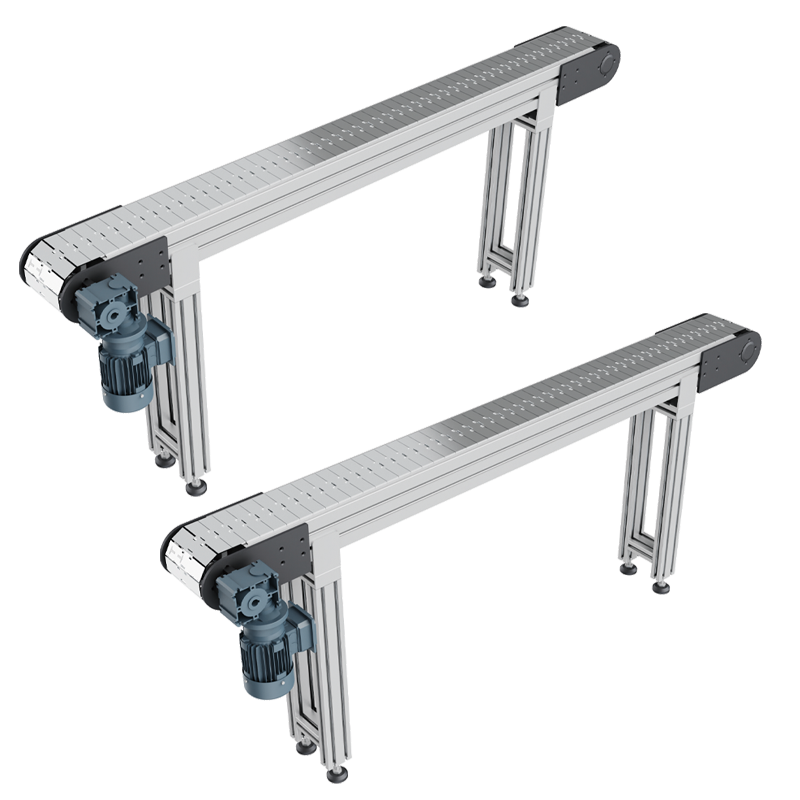

Toshine Slat Chain Conveyor System

What is a Slat Conveyor?

A slat conveyor is a type of conveyor system that uses slats and a chain to move components along an assembly line. This type of system is frequently employed in production settings. And we carry out tasks with parts positioned directly on the conveyor. Steel panels are securely attached to the chain using special fittings. And an electric motor and gearbox drive the chain.

Consequently, slat conveyors rank among the most commonly used systems for moving parts along an assembly line during active work. They are particularly effective for applications where components are assembled at an ergonomic working height.

Aanvullend, slat conveyor systems enable production operators to work from one or both sides of the line. Fixtures can be added to the slats, allowing parts to rotate 90, 180, or even 360 degrees for improved ergonomic access. During model changeovers, workers can adjust or replace tooling or fixtures, making the conveyor adaptable for new applications.

In the automotive manufacturing sector, slat conveyor systems transport components such as instrument panels, center consoles, and door trims. In de tussentijd, we also emply them in engine and powertrain assembly, as well as in the sub-assembly of frames and axles.

On a larger scale, slat conveyors facilitate the movement of vehicles after fitting them with chassis components, transporting them to the final assembly line, often known as a ‘flat top’ conveyor line. Customers often refer to these systems as slat conveyor belts because the slats function similarly to a traditional belt conveyor.

Technical Specifications

Model NO. Condition Voltage Power Feature HS Code Origin Production Capacity

TOSH-TC New 110V/220V/380V 90/120W Sturdy and Durable 8428330000 China 1000 Sets Per Month

Slat conveyors are available in various lengths, widths, heights, controls, and accessories to meet diverse application needs. Daarnaast, the slats materials can be mild steel, stainless steel, or plastic. Depending on the design, products may sit loosely on the slats or be mounted on one or more fixtures. Here are some typical specifications, with many combinations available:

- Widths can range from 12” to 108” between frames.

- Speeds can vary from 10 feet per minute (FPM) to a maximum of 60 FPM.

- Available with fixed or variable speed control.

- Adjustable legs are standard.

- Supports continuous or indexing movement from station to station.

Benefits of Slat Conveyors

- Ideal for assembling products on a moving assembly line or at workstations when halting the line, providing a stable working surface.

- Effective for applications where part access is primarily from above; for access from both sides, consider an overhead conveyor with a swiveling fixture.

- Suitable for products that we need to securely hold in place during transport along the line.

- Fixtures should be appropriately sized to ensure they can return beneath the conveyor. If limiting space, we need raise the conveyor by 10” to 24”, with a compensating work platform added for ergonomic access.

- Industrial slat conveyors can function in continuous or indexing modes, stopping and starting to move products using sensors.

- Well-suited for robotic loading and unloading tasks, as the fixtures remain in consistent locations. With proper guarding, both human and robotic operations can coexist on the same assembly line.

- We can adjust speeds easily when equipping the system with a variable frequency drive (VFD).

When Not to Use a Slat Transportband

- Accumulation Needs: Slat conveyors do not permit products to accumulate since hold items in fixed positions. For accumulation purposes, consider roller conveyors with pallet systems or overhead power-and-free conveyors.

- Curved Paths: Slat conveyor systems operate only in straight lines and are not suitable for moving products around curves.

- Product Flexibility: Slat conveyors are not very flexible in accommodating various tooling for different models unless the tooling can handle all variations. For greater flexibility, overhead conveyors or roller conveyors with pallets may be more suitable options.

Digital Transportband Design for Optimal Ergonomics

Bij Toshine, we design all our conveyors by using advanced 3D CAD software. Our conveyor designs encompass the entire assembly line, including tooling, slat conveyor chains, overhead lighting, power outlets for torque tools, and all necessary tool rails and spring balancers.

We adhere to detailed ergonomic standards to ensure that assembly operations align with automotive and other industry requirements for height, reach, and operator comfort. As a leading slat conveyor manufacturer, we prioritize making your new conveyor as ergonomic as possible.

All safety systems are included, such as guarding, emergency stops, and pull cords. Daarnaast, we design and assemble the conveyor at our facility before delivery. You can attend for testing and run-off, after which we can reinstall at the final assembly plant location.

If you want to learn more about slat conveyor design, the booklet from CEMA (Conveyor Equipment Manufacturers Association) is an excellent resource for engineers.

Control Systems

The control system can range from a simple on-off switch for the electric motor to a more advanced programmable logic controller (PLC). A PLC can accept inputs from sensors and manage the movement of the machinery.

The slats can move continuously, or the motor can cycle on and off to transport slats and tooling between stations. For enhanced safety, workers can place emergency stop buttons and pull cords at intervals along the length of the system.

When cycle time is critical, a variable frequency drive (VFD) can control the motor’s speed, allowing for smooth acceleration and deceleration as the conveyor indexes from one station to another.

VFDs are also beneficial if you need to adjust the conveyor speed, such as when assembling the product. Some VFDs come with basic sensor inputs and logic processing. So that makes them a viable option if a PLC is not necessary.

Contact Us for Assistance

Call us at 0086 159 4048 3014. Our team is ready to help you with load calculations, speed requirements. And any other needs you may have as a top slat conveyor manufacturer.

If you need help understanding other types of conveyors, which ones to use, or how to specify them, this step-by-step guide will provide valuable insights.