Automatic pallet roller conveyors are a type of conveyors. And you can use that in many fields. Besides roller conveyors, there are other types conveyors you could choose. Unlock unparalleled productivity and efficiency—our cutting-edge industrial automation solutions are according to revolutionize your operations, allowing you to surpass your performance goals with ease and precision!

Description

About Conveyor

Automatic pallet roller conveyors are widely used in production lines, logistics and warehousing. In production, conveyors are indispensable. Conveyors can greatly improve the efficiency of factory logistics transportation, so conveyors are increasingly used by factories. At the same time, different customers have different needs for conveyors, and their personalized needs are increasing.

To quickly respond to the market and design, conveyor products need meet customer needs. That is of great significance to every conveyor manufacturer.

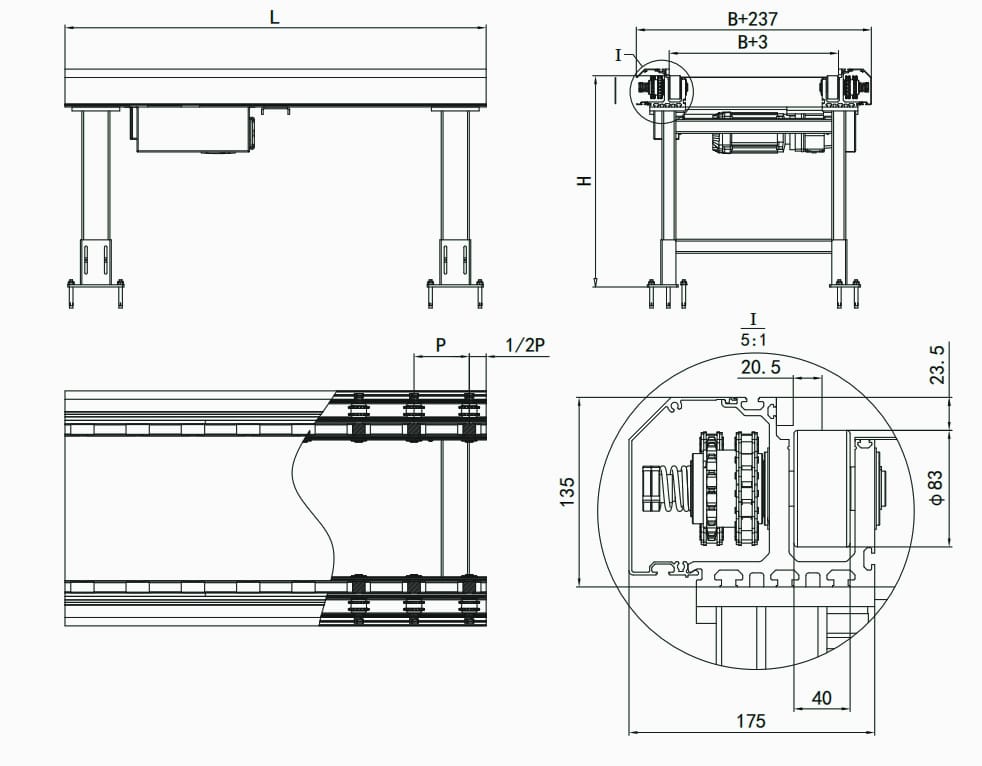

Specifications:

Model T Conveyor length L Conveying Width W Conveyor height H Conveyor Speed V Motor Position Motor Direction

TOSH-5-CS 400~6000mm 160~1200mm As needed Max 20m/min Refer to page 12 Refer to page 12

Product Features:

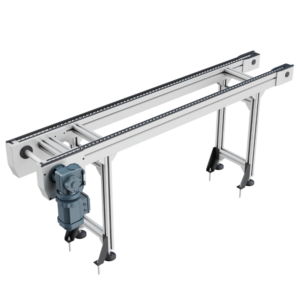

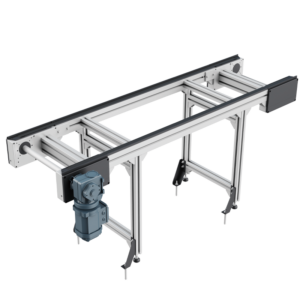

- High modularity, comprehensive supporting mechanisms, and easy maintenance.

- Conveying medium: rollers.

- The frame of the line comprises specialized high-strength aluminum profiles, featuring a doubly supported structure for added stability, standardized section connections, and double-sided sprocket-driven transmission.

- Suitable for heavy-duty Pallet conveying, enabling automatic Pallet circulation and flexible control.

- Toal load ≤ 3000KG.

- Applicable for accumulation conveying.

Dimensional Description:

Application:

TOSH-5: Mainly in scenarios with heavy loads, featuring a robust structure capable of withstanding significant impact loads. Often utilized in automatic assembly production lines for automotive engines and transmissions.

Automatic Pallet Roller Conveyors Feaures during Use:

- Continuous efficiency: Repeating the production process of the assembly line is according to a certain rhythm, and its operation is efficient and has a strong rhythm. We do not allow continuity in the middle. Therefore, we do not allow excessive waiting time of products and processing stop time of equipment at all. Therefore, an assembly line shutdown due to various factors (such as component quality, material distribution delays or wrong materials that often let line shutdowns) is usually as a comprehensive evaluation index. And that index is to measure the production of assembly lines or production.

- Balance: The production capacity of each process on the assembly line is balant and proportional, and bottlenecks are not allowed. The distribution of production materials must be in place according to the rhythm, on time, in accurate quantity, and in a qualified manner.

- Simple one-way: The assembly line only produces one or a few series of products with similar technical layout, and the materials only move in one direction.

- Dominance: Various auxiliary processes of production and material distribution are the keys around the assembly line.

- Professionalism: On the assembly line, each process (a work center in production) is highly specialized. We must arrange each process in the order of the technical process, and each process only completes one or more processes.

Precautions During Operation of Automatic Pallet Roller Conveyor

- During the operation of the power drum, we should note that we must repair the bearing with suitable tools. Especially when repairing and disassembling, please notice not to use existing items instead.

- Notice that the bearings of the power drum will not suffer from serious corrosion problems. Workers should wear gloves during operation. Sweaty palms will cause important parts of the mechanical equipment to rust.

- The bearings of the power drum and many parts around the bearings require regular cleaning and maintenance. Based on this, dust and debris almost can not fall into the bearing and cause damage to the bearing.

- When using the bearings of the electric roller, we should note that it is prohibited to be subjected to strong impact force. If we did, it will directly cause serious cracks during the operation of the equipment. If serious, it will lead to cracks and cracking.

- Finally, during the operation of the power drum, the operator should know the operating status of the equipment and bearings to ensure that certain quantitative aspects can be compensated. Besides those issues, we need make necessary work standards and operational standards.

Control Motor Balance Problem of Roller Conveyor

Multiple AC variable frequency motors drive long-distance roller conveyors. Because of many factors, imbalant power in each drive motor is inevitable. Although, power imbalance causes unequal load distribution on the motor, excessive wear on the drive device, and even burns out the motor. Therefore, power control must be balant on the roller conveyor.

Factors of affecting motor balance can be roughly divided into two categories:

First, it is is the influence of static factors. Meanwhile, it mainly depends on the design of static parameters. Good design can achieve the ideal effect of static power balance.

Second, it is the influence of dynamic factors.So the power imbalance is a transient process. The problem of dynamic power balance mainly depends on the response speed of the transportation system used to eliminate dynamic power imbalance, which can meet the engineering response speed requirements. , it plays a role in dynamic power balance.

Through the modeling analysis of the roller conveyor, we can conclude that the static factors affecting the power imbalance of the multi-point drive roller conveyor include:

1. The enclosing angle of the drum;

2. Friction factors between the steel core belt and the roller;

3. Mechanical characteristics of each motor;

4. The transmission ratio and efficiency of each mechanical transmission device;

5. The elastic modulus of the conveyor belt;

6. The diameter difference of each driving roller;

Automatic Pallet Roller Conveyor Conclusion

As we can see,these factors relate to the power distribution on the roller. These parameters are important selection parameters when designing the roller conveyor. On the contrary, after designing the roller conveyor system, the power distribution on the roller is also determined. This is the key point of static power balance.

And we must strictly control that during design, otherwise any power balance measure will not achieve the purpose of power balance. So the dynamic factors of power imbalance include: total resistance (determined by factors such as transportation volume);

The electromagnetic torque output by the motor (AC asynchronous motor). For a specific roller conveyor, that determines the static factors during design, so we can only adjust the power balance of the motor through the frequency of the power supply.

So if you meet that issue, come on and contact us. We will provide he best solutions for you.

-300x300.png)