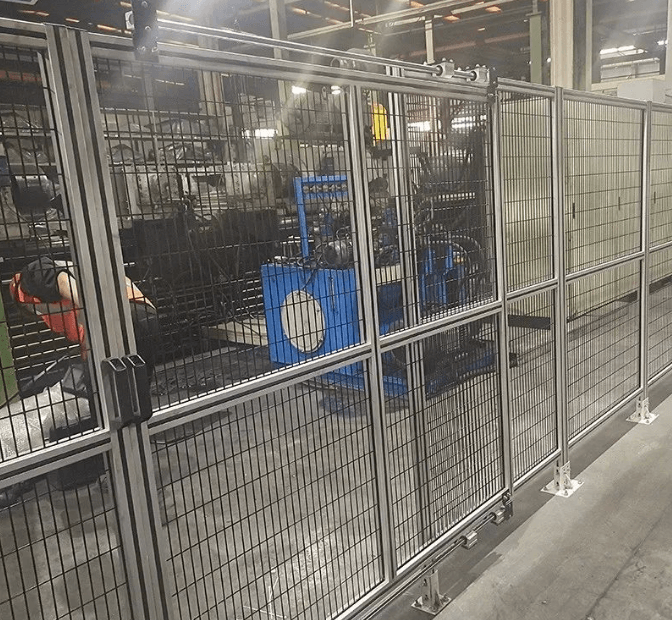

Safety Guarding and Fences are essential components designed to ensure the protection of personnel and equipment in industrial environments. These systems are engineered to create a secure perimeter around machinery, robots, and other hazardous areas, effectively minimizing the risk of accidents and improving workplace safety.

Description

Custom T-Slot Safety Guarding Solutions

Safety guarding and fences are with industrial aluminum profiles. They are beautiful, easy to clean and corrosion-resistant, have high load-bearing performance and have a long service life. You can choose different baffles according to your needs.

For example: mesh grids are cheap and easy to install, acrylic panels are transparent. But have diversified colors, aluminum alloy panels have high hardness, elegant appearance, and strong anti-collision properties. It is suitable for various mechanical equipment and is modular and multi-functional without complex design and processing.

Safety guarding and fences have a relatively stable structure and can carry mechanical equipment of a certain weight. They have a high safety factor and people can use to isolate some mechanical equipment from working and divide the safety range, blocking direct contact between people or objects and the equipment, and serving as a safety warning.

Safety guarding and fences can isolate the mechanical equipment from direct contact with the working environment. Also prevent dust and water mist generated during production operations from entering the mechanical equipment. Besides, protect the mechanical equipment, and extend the service life. It can improve the environment and enhance the image.

The use of aluminum profile equipment hoods can give the dirty working environment a new look. And make production more standardized.

Standards for Aluminum Alloy Safety Guarding and Fences

The function of the aluminum alloy safety guarding and fences is to prevent production personnel from entering dangerous places or being injured during the operation of machinery and equipment. The main purpose is to protect the safety of production personnel and machinery and equipment.

Aluminum alloy profile safety fences are suitable for factory workshops, mechanical equipment transmission parts, dangerous parts protection and barriers, company pedestrian passages, operating platforms, and places with risk of falling. Aluminum alloy profile safety fences have three types

No entry security fence. This is to prevent close proximity and contact with dangerous parts. Safety fence to prevent falls, the purpose is to prevent falls from heights.

The function of area division fence is to divide areas. We can select the height according to different places of use.

Workshop safety guarding and fences, we also call it industrial protective fence, equipment protective fence, pit entrance guardrail, robot safety fence, workshop protective barrier, regional partition guardrail, etc.

Their heights are all standardized and cannot be set arbitrarily, and in some automated machinery and equipment industries, some safety fences are closed, such as robot production sites, machinery fences, welding machine equipment sites, etc. We need customize the height of the safety guarding and fences in these special places of use needs according to the actual situation.

Advantages

- The aluminum profile equipment cover can be dust-proof, waterproof and oil-proof. It can isolate the contact with the surrounding environment of mechanical equipment and extend the service life of mechanical equipment.

- The aluminum profile equipment hood has better heat insulation and temperature resistance. It can effectively protect mechanical equipment from damage in high temperature environments.

- The aluminum profile equipment cover is anti-static, which can prevent the safety of mechanical equipment during operation.

- Aluminum profile equipment hoods can improve the production environment and regularize the area.

- The aluminum profile equipment cover is easy to disassemble, simple and fast.

Why Choose Aluminum Profile Safety Guarding and Fences?

Aluminum profile fence is a high-performance fence system with aluminum profiles and connectors. Compared with fences made of other materials, aluminum profile fences have the following advantages:

- Lightweight: Aluminum profiles are lighter than steel and other metal materials, so the aluminum profile fence system is also lighter and easier to install and maintain.

- Corrosion resistance: Aluminum profiles are not easy to rust and have good corrosion resistance. So the aluminum profile fence system is suitable for high-corrosion environments such as seaside and chemical plants.

- Strong durability: Aluminum profiles have high strength and hardness, so the aluminum profile fence system is not easily damaged and has a long service life.

- Beautiful appearance: The aluminum profile has a smooth surface and various colors, which not only can beautify the environment, but also has strong adaptability.

- Quick installation: Aluminum profile fence adopts modular design, which is easy and quick to install.

To sum up, when choosing a fence, aluminum profile fence is undoubtedly a better, more reliable and more beautiful choice. Its durability, safety and environmentally friendly features make it the first choice for all types of projects. Contact us to choose an aluminum profile fence to add value and protection to your project!

Features and Uses of Industrial Aluminum Profile Robot Safety Barriers

Robot safety barriers serve a crucial role in automated production environments by shielding robots and manipulators. Their primary function is to maintain a clean work area for robots. Also block out debris that could disrupt operations and lessen the likelihood of workplace accidents.

Characteristics of Aluminum Profile Safety Barriers: Durability against corrosion is a major concern for safety barriers. While wrought iron barriers often rely on a protective coat of paint, this is only effective if the iron is properly pre-treated; otherwise, it’s prone to internal corrosion that leads to flaking paint. Aluminum profile barriers, on the contrary, undergo an anti-oxidation treatment in their manufacturing process.

This treatment creates a protective oxidation layer, sometimes up to 12μ thick, which provides formidable resistance to corrosion. The aluminum profile fences, as a result, resist oxidation over time. And require minimal maintenance, ensuring the consistent performance of the barrier.

Applications of Robot Safety Fences: The primary purpose of robot safety fences is to protect both machinery and personnel within automated production areas. They act as a shield to prevent debris from compromising robot functions and causing unnecessary downtime. They also serve as a deterrent, preventing personnel from accidentally entering the operational zone of manipulators and potentially sustaining injuries.

Safety fences, we design to delineate a secure area within the production site, tailored to the specific motions of the robots in use. This strategic placement significantly elevates safety levels on the production floor while also safeguarding the robots themselves.