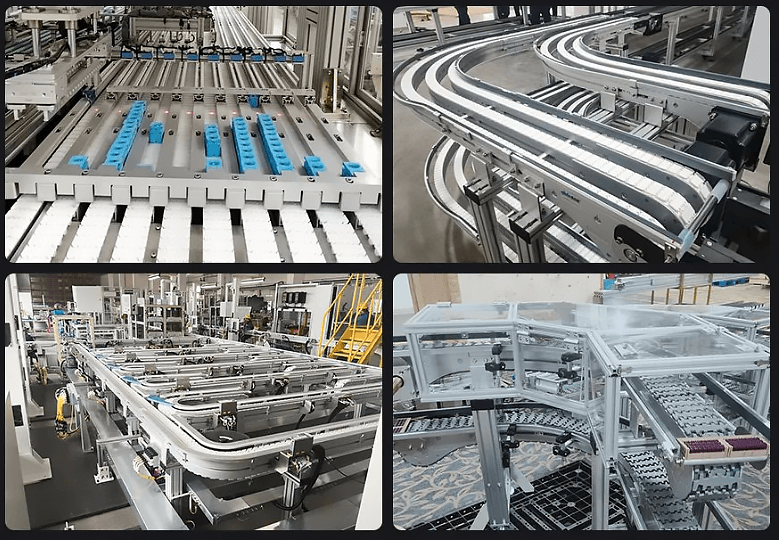

Crafted with durable materials, this flexible chain conveyor conveyor offers a hygienic, modular design perfect for the dynamic needs of the pharmaceutical, cosmetic, food, and bearing industries. Achieve seamless automation and efficient material handling with minimal downtime, tailored to elevate your production line to peak efficiency.

Description

Flexible Chain Conveyor

Conveyor Data:

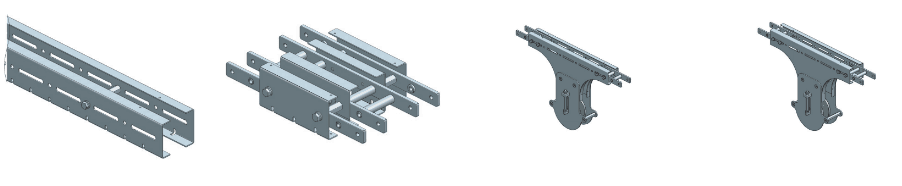

Basic Structure of Flexible Chain Conveyor

The basic components of flexible chain conveyors system include central control system and flexible conveyor belt. The central control system is generally including PLC or PC or single chip microcomputer, sensor, control console, actuator. While the flexible conveyor belt is including the following basic parts.

- Conveyor chain: Made of high-strength engineering plastic. We can divide It into flat chain, universal chain, steel top chain, wedge chain, ball chain, brush chain, elastic chain, etc. The conveyor chain uses the carefully designed staggered yielding structure and hinge cooperation. That is between the two links to enable the conveyor chain to turn freely in the horizontal and vertical directions. Thereby realizing the turning of the entire conveyor belt in space.

- Conveyor beam: It is including aluminum alloy profiles or stainless steel materials with anodized surface and friction slide rails. We can divide it into standard type and reinforced type.

- Conveyor frame: It is also including aluminum alloy profiles or stainless steel materials with anodized surface. It is divided into light, medium and heavy types.

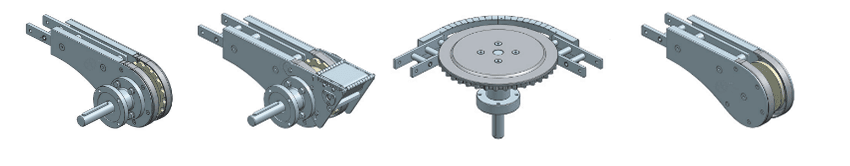

Other Components

(4) Drive device: It is including an aluminum drive head and tail die-casted by powder metallurgy. We can divide it into single drive, double drive and intermediate drive. The active element is generally a motor.

(5) Guide device: The two side guardrails that can keep the material running in the middle of the chain plate.

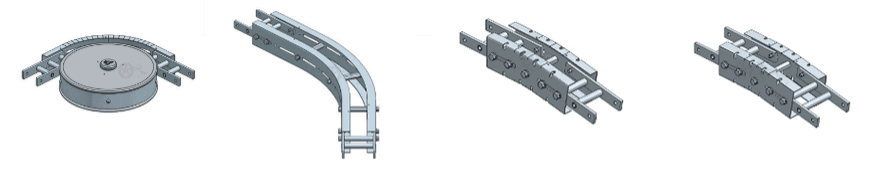

(6) Turning device: The internal support device when the chain plate turns. We can divide it into horizontal elbow, vertical elbow, horizontal wheel elbow and horizontal wheel.

(7) Accessories: There are connectors, liquid trays, etc.

Assembling the above parts together will form a flexible conveyor. Of course, workers can install some automatic sorting devices, assembly devices, and detection devices on the conveyor belt as needed to improve efficiency.

Characteristics

The flexible conveyor has the following characteristics:

(1) Clean: People assemble the entire conveyor line from high-strength engineering plastic chain plates and anodized aluminum alloy profiles. The chain plates are generally pure white, and the equipment does not require lubrication, is pollution-free, and will not be corroded, which complies with GMP standards.

(2) Quiet: The equipment operation sound is less than 30dB.

(3) Dexterity: The flexible conveying system is including arbitrarily disassembled components. With vertical and horizontal curves of different radii, people can transport products in any 3D space. And people adjust it anytime and anywhere according to the current production situation.

It can complete horizontal, climbing, vertical, turning, spiral, clamping, hanging, flipping, rotating and other conveying forms. There is no need to replace the entire conveyor belt due to the extension of the automatic production line.

(4) Convenient: The overall conveyor line installation does not require any special tools. Only common hand tools are needed, and basic disassembly and assembly work can be completed by one person.

(5) Stability: Stable performance and guide devices can ensure that the conveyed products will not fall or slide during the conveying process.

Contribution of Flexible Chain Conveyors

By installing flexible conveyors, the possibility of conveying to any location is realized, the manpower and time of manual handling are reduced. That not only reduces labor expenses, but also improves the efficiency of the entire production line.

In addition, since the continuity of the process is promoted, we reduce the accumulation of work-in-progress (WIP) and temporary land use , save the factory production land, and improve the land use efficiency. In addition, the flexible conveyor can also realize the function of transporting goods between floors by cooperating with the lifting.

We can make the flexible conveyor into various conveying modes. Such as supporting, pushing, hanging and clamping to form various functions such as gathering, diversion, sorting and converging.

Besides, we can equip it with various pneumatic, electric and motorized automatic control devices according to different needs. It can form various forms of production lines and storage lines. So as to improve efficiency, save costs and increase benefits. The use of flexible conveyors will become more and more extensive in the future.

In Conclusion

The Flexible Chain Conveyor presents a sophisticated three-dimensional transport solution, featuring a lightweight aluminum alloy structure and a durable plastic steel conveyor chain. Noted for its smart design and standard modular construction, the system assembles quickly and operates smoothly—quiet and free from pollution.

Particularly advantageous in environments requiring rigorous cleanliness, limited space, and high levels of automation, it excels with its minimal turning radius and impressive incline capabilities, making it the conveyor of choice in the pharmaceutical, cosmetic, food, and bearing industries for streamlined automated connections.

Versatile and unobtrusive, the conveyor’s size and function are adaptable, easily reconfigured for tasks including supporting, pushing, suspending, and securing materials. With the capacity to integrate various mechanical, electronic, and automated control options, it enables the creation of diverse production line arrangements. That will meet the specific needs of different users.