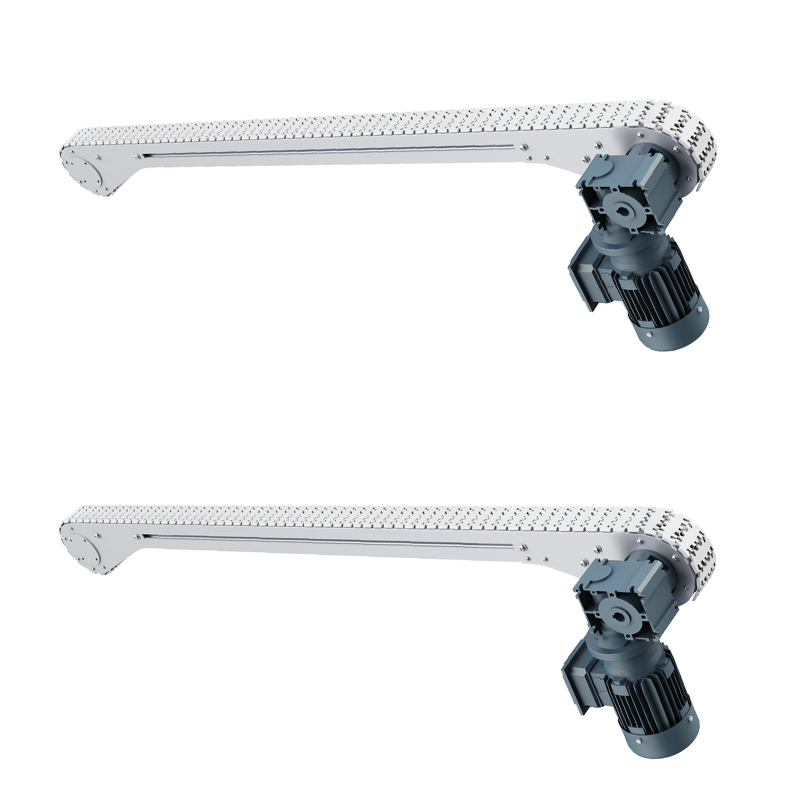

Engineered for efficiency, flexible plastic chain conveyors feature a durable plastic chain plate that glides products along the production line with ease. Its adaptability shines in its ability to navigate complex routes with various elevations and angles.

Ideal for industries requiring hygienic conditions and swift, reliable product movement, this conveyor is a low-maintenance solution that maximizes productivity while minimizing operational noise. Experience seamless integration into your workspace, perfect for the dynamic demands of modern manufacturing.

Description

Flexible Plastic Chain Conveyors

As automation constantly advances, conveyor systems have become integral components of automated warehousing and logistics operations. Conveyor equipment is categorized by its primary operational components. And it can be into several types including chain conveyors, belt conveyors, pneumatic conveyors, and screw conveyors. Flexible plastic chain conveyors are one type.

Out of all conveyor systems, chain conveyors stand out due to their extensive range of specifications and their prevalent application across various industries.

Flexible Chain Conveyor in the Biopharmaceutical Industry

In the burgeoning realm of biopharmaceuticals—a field marrying cutting-edge biotechnological advances with new pharmaceutical discoveries—flexible chain conveyors have become pivotal. As the industry hastens forward, production line efficiency, adaptability, safety, and eco-friendliness are increasingly critical to its evolution. Herein, flexible chain conveyors, armed with a suite of unique benefits, prove indispensable for the sector’s push toward high-caliber growth.

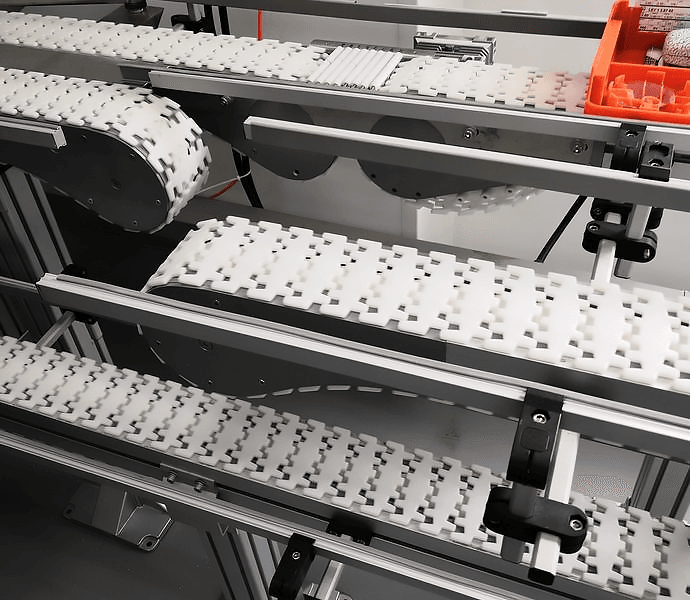

These conveyors, merging modularity with a three-dimensional conveying system, boast agility, aesthetic appeal, and lightweight construction. Their structured use of an aluminum alloy frame and a composite of plastic. And steel for the conveyor chain results in an installation, culminating in an operation. And that is stable, compact, whisper-quiet, and resilient against contamination.

Their implementation is especially valuable in biopharmaceutical production environments that mandate stringent hygiene, spatial efficiency, and purity.

Foremost, their ability to expedite the movement of raw materials, intermediates, and final products crystallizes their contribution to biopharmaceutical manufacturing. As the flexible chain conveyor impels its chain plates forward via the rotation driven by the sprockets, it ensures not just rapid but also precise transit to predetermined destinations, uplifting production efficiency in its wake.

Furthermore, the intrinsic modularity and customizability of flexible chain conveyors are a boon to the biopharmaceutical sector. Given the array of biopharmaceutical goods and the often-transforming landscape of production lines, these conveyors can be reconfigured in tune with on-the-ground requirements. Whether the task at hand is to support, push, hang, or clamp materials during conveyance, this flexibility augments the malleability and applicability of the system.

Flexible Plastic Chain Conveyor Importance

Quality and safety, twin pillars within the biopharmaceutical industry, are robustly supported by flexible chain conveyors. They guarantee the preservation of material stability and integrity throughout transit, preventing damage or contamination. Coupled with their low noise, pollution-free performance, they align with the industry’s stringent environmental standards. Additionally, the potential to integrate various automated controls elevates their stance in safety and reliability.

Beyond these traits, flexible chain conveyors also excel in energy consumption and ecological stewardship, aligning with the rising wave of eco-consciousness in the biopharmaceutical landscape. Featuring sophisticated transmission mechanisms and reduction gears, they minimize energy use and emissions, thereby fulfilling heightened environmental expectations. Their compact framework further aids in the reduction of the factory footprint, complementing energy-saving efforts.

The success stories stemming from the deployment of flexible chain conveyors in biopharmaceutical settings are many. One such narrative involves a major pharmaceutical entity that harnessed these conveyors to boost the efficiency and accuracy of transporting essential production elements, optimizing line flexibility, elevating output, and curtailing costs. The conveyor’s stable operation and eco-friendly attributes also broadened the company’s environmental credentials and competitive edge.

In summary, the role of flexible chain conveyors in the biopharmaceutical industry is transformative. Championing efficiency, adaptability, safety, and environmental harmony, they buttress the industry’s ascent to exceptional standards. Looking ahead, as the biopharmaceutical sector continues to flourish, flexible chain conveyors are poised to amplify their contributions. And remain instrumental in the industry’s quest for quality and excellence.

Flexible Chain Conveyor Introduction And Features

All in all, the Flexible Chain Conveyor is a highly adaptable system, specifically engineered to enhance processing and production efficiencies. Also ideal for transporting raw materials, semi-finished goods, or final products. Utilizing a plastic chain plate, this conveyor system operates through frictional sliding, providing continuous material movement.

We commonly employ it in settings requiring assembly line operations. And we use it extensively across various sectors, including food and beverage, paper product transport, the cosmetics industry. Besides, tobacco production, motor manufacturing, and the machining of mechanical components. Customizable to user requirements, it allows for the formation of diverse production line configurations.

Key Benefits:

- Intelligent Design: Composed of easily detachable parts, it boasts a flexible conveyance system. That supports multi-dimensional spatial product transport, adjusting to production changes on-the-fly. It can handle horizontal, inclined, vertical, and turned paths, as well as spiraling, clamping, suspending, flipping. And rotation without the need for a complete conveyor belt replacement if the production line expands.

- User-friendly: With a modular setup, this system can be rapidly established to create a production line. Installation is simple, requiring no specialized tools—just basic hand tools are sufficient, enabling a single individual to perform most assembly and disassembly tasks.

- Reliable: Designed for stable operation, integrated guide devices ensure that products remain secure and stable, preventing tipping or slipping throughout transit.

- Quiet Operation: The equipment operates with minimal noise, creating a more comfortable work environment.

- Hygienic: Constructed from high-strength, engineering-grade plastic chain plates and anodized aluminum profiles , the system operates without lubrication. Thus avoiding pollution and corrosion, and adheres to GMP (Good Manufacturing Practice) standards.