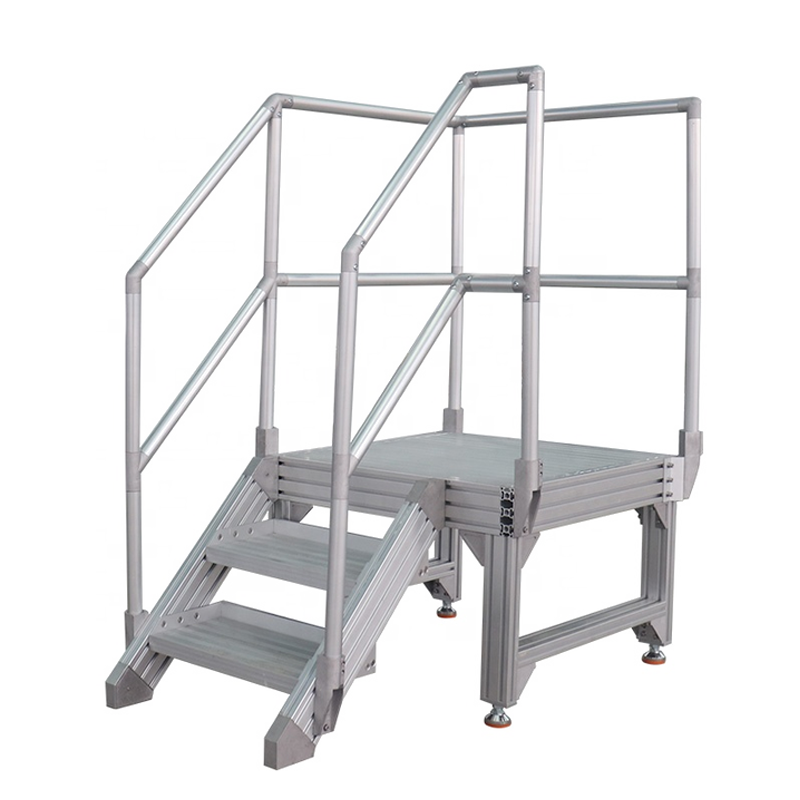

Aluminum work platforms constructed from premium aluminum profiles offer a combination of robustness, safety, and versatility. Adjustable to various industrial requirements, these structures boast anti-slip treads and we can customize specific dimensions, ensuring secure and efficient access across different levels within the workspace.

Description

Mobile Aluminum Work Platforms

Aluminum work platforms are a type of climbing and line-crossing platform commonly used in large factories that require mid-to-high-altitude production operations. Because mobile aluminum work plarforms can save space and improve production and processing efficiency.

But the big difference is that it uses aluminum profiles.

As we see, aluminum profiles are beautiful and durable, anti-corrosion and wear-resistant, easy to disassemble and assemble. Besides, we can customize it in size. Currently, most industrial aluminum work platforms on the market, we customize by using industrial aluminum profiles.

Besides, aluminum work platforms are mainly assembled from handrails (aluminum tubes), European standard 40160 aluminum profiles, and patterned aluminum pedals. According to the load-bearing requirements of different parts, we can use aluminum profile models of different sizes.

Commonly used aluminum profile specifications are 40160 aluminum profiles, 8080 aluminum profiles, etc. Because of the need to bear a large load and for safety and stability reasons, it is generally recommended to use large and heavy-duty materials.

And the connection method of the bottom profile of the platform is mostly at a 45-degree angle. We connect the handrails with step pipe connectors. Such as 45-degree four-way, 135-degree two-way, etc. We connect the armrest to the lower part using step accessories, including side bases, corner plates, etc.

We mostly connect the aluminum profile frame structure at the bottom with strong angle pieces. The bottom of the platform uses corner pieces and nylon hoofs to stabilize the steps. If there is no need for movement, we can fix it on the ground with feet. If there is a need for movement, we can install it on casters.

Detailed introduction of Aluminum Work Platforms

We mainly use aluminum work platforms for the upper and lower entrances and exits of industrial production workshop equipment maintenance platforms or step and walkway systems for climbing operations; we need use the step system in conjunction with the maintenance aluminum work platforms, workshop operation platform, and production line bridge walkway system. Forming a complete industrial escalator step and platform system.

Aluminum work platforms features:

The main body of the aluminum work platforms system is an aluminum profile frame, and we can quickly assemble with the help of matching connection accessories. The step platform system is developed on the basis of the 6063 series of industrial aluminum profiles.

And is also part of the industrial aluminum profile rapid assembly system, which is systematic. The product application model facilitates the flexible application of aluminum profile products in more fields and industries to meet different usage needs.

Application scenarios of Aluminum Work Platforms:

We mainly use aluminum work platforms in factory workshops, airports, high-speed rail stations and large equipment maintenance work. We can flexibly design according to application scenarios to meet production needs.

The aluminum work platforms system is an aluminum profile escalator step platform system developed based on the needs of large-scale industrial production workshops and heavy industrial equipment construction/maintenance. It develops non-standard escalator step platforms into a complete escalator step platform system. It has realized a standardized, systematic and modular product model.

Besides, it is more convenient for users to use flexibly. And greatly improves the stability of the product performance of the industrial escalator step platform system. Modern aluminum work platforms materials are industrial aluminum profiles, with a load-bearing capacity of more than 3,000 kilograms, easy assembly and disassembly, and we can recycle and reuse it.

Benefits of Aluminum Work Platforms Treads:

- A vast array of aluminum profile specifications are available, enabling selection based on the required span and load capacity for the stair treads.

- Stair tread dimensions are highly versatile and we can customize according to specific needs.

- Utilizing industrial aluminum profile accessories for assembly avoids the need for welding, resulting in a flexible installation process and an aesthetically pleasing, sturdy finish that can be easily dismantled when needed.

- Optional addition of casters allows for mobility, offering a significant advantage over traditional, immovable stair treads.

- Constructed for durability, the stair system resists corrosion, wear, and rust, maintenance-free, making it ideal for maintenance platforms in varied production environments and around large machinery.

Safety Considerations:

- Material Specification: The application environment dictates the necessary aluminum profile specifications. For stair tread applications that bear considerable weight, profiles typically exceed 4040 specifications, whereas spans demand 8080 profiles or larger to support over 3,500 kilograms.

- Stair Angle: The staircase’s angle of incline depends on the available space and intended use. It is with common angles ranging between 45 and 60 degrees.

- Anti-Slip Surface Selection: Aluminum alloy checkered plates are commonly used for their anti-slip properties to ensure safety.

- Span and Structural Support: Larger spans necessitate stronger support, often requiring larger aluminum profiles to prevent bending and deformation.

Aluminum alloy ladder or steel ladder, which one is better?

1. Durability

Aluminum work platforms have better corrosion resistance and rust resistance than steel ladders. As long as we do not use them in an environment with high acid and alkali, aluminum alloy ladders will hardly rust. As we know, and the surface is anodizing and will not fade. Steel ladders also have anti-rust measures, but they are prone to rust after long-term use, affecting their appearance.

2. Portability

Aluminum work platforms are lighter than steel ladders, easy to carry and move. And are suitable for use in a variety of indoor and outdoor situations. Although steel ladders are stronger, they are also heavier and more difficult to carry and move.

3. Security

Aluminum work platforms have strong pressure resistance and wear resistance and are not easy to deform and break. At the same time, aluminum work platforms have good anti-skid properties . Besides it will not slip easily even if there are dust and water droplets on the soles of the feet. So the anti-slip performance of steel ladders is relatively poor and it is easy to slip or slip.

4. Structural stability

The structure of the aluminum work platforms is relatively simple, and riveting fixes the components. So it has good stability and long service life. While the structure of the steel ladder is relatively complex. The most important is that we need to connect it through different components. If the connection method is not stable enough, it is easy to affect the quality of the ladder lifespan.

Conclusion

To sum up, aluminum work platforms and steel ladders each have their own advantages and disadvantages. If you need to be light and easy to carry, have high requirements for anti-rust and anti-slip performance. Because it has diverse usage situations, it is recommended to choose an aluminum alloy ladder.

If you need higher pressure resistance and load-bearing capacity, and use it in an environment with less aesthetic requirements. Because it is more appropriate to choose a steel ladder. Only by choosing a ladder that suits you can you better ensure safety and convenience.